Source: Efe

The construction of buildings based on 3D printing could mean that the new industrial revolution has arrived in the industry and is an opportunity to stand out from competitors, lower costs and avoid the economic crisis.

A consortium of major companies is participating in a strategic project, funded by the Spanish Ministry of Economy and Competitiveness and the Spanish National Infrastructure CDTI, which aims to introduce 3D printing technologies in the construction industry, both in the field of new construction as well as in the renovation and restoration of heritage.

The project, entitled "3DCONS: New Construction Processes through 3D Printing", has a budget of just over eight million euros and a completion period of three and a half years, after being approved last November.

The project is "a gateway to new ways of building", where it will be possible to go from "a three-dimensional design to manufacturing a building element in an automated way", according to Carlos Martínez Bertrand, deputy director of R&D at Vías y Construcciones (ACS Group).

"The development of this technology from Spain will place us at the forefront of the industry on an international level both in the field of construction, where we already hold a prominent position, and in other technological industries with high added value," emphasised Martínez Bertrand.

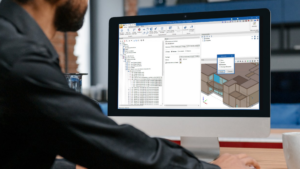

In fact, its implementation is a compendium that encompasses the development of robotics, the search for new ranges of materials for construction and the technological boost of design and construction, according to two CYPE executives, Benjamín González and Carlos Fernández.

The fall in the price of technology means that in less than a decade the use of 3D printing will be common in many areas of economic activity, making the construction industry's entry into the sector "essentially as soon as possible", says CYPE.

The project aims to develop new robotic systems for printing full-scale building elements or rehabilitating façades by direct printing on vertical elements, with little or no disruption to building users, which is a truly unprecedented challenge

The project aims to develop new robotic systems for printing full-scale building elements or rehabilitating façades by direct printing on vertical elements, with little or no disruption to building users, which is a truly unprecedented challenge.

"We are also looking for new ranges of materials that allow us to control their thermal and aesthetic properties at each application point and new design tools that convert drawings and models of the building into manufacturing orders for full-scale printing systems," explained Martínez Bertrand.

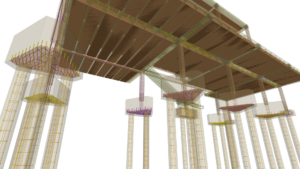

By avoiding the need for moulds or formwork systems, 3D printing technology makes it possible to produce geometric shapes that were previously unthinkable on a practical level, opening up creative freedom for architects.

One of the two practical applications of the project focuses on the printing of single or prefabricated parts made to order, which contributes to new solutions such as elements with variable curves that adapt better to building supports and to savings in materials.

Other advantages of this technology are the reduction of occupational risks associated with working at heights and the optimisation of material consumption with zero waste production.

The companies involved in the project are Vías y Construcciones (project coordinator), Saint Gobain Placo Iberica (plaster and laminated plasterboard producer), Lafarge (mortar and concrete manufacturer), Proingesa (process automation engineering) and CYPE.

Other participants include Geocisa, whose activity is mainly focused on heritage renovation, and Atanga, an architecture and engineering firm specialising in Building Information Modelling (BIM) and the integration of 3D systems in construction.

The Eduardo Torroja Institute for Construction Sciences (CSIC), the Universidad Politécnica de Madrid, the Universidad de Burgos, the CARTIF Technology Centre and the CIM Foundation are collaborating in the development of the project.