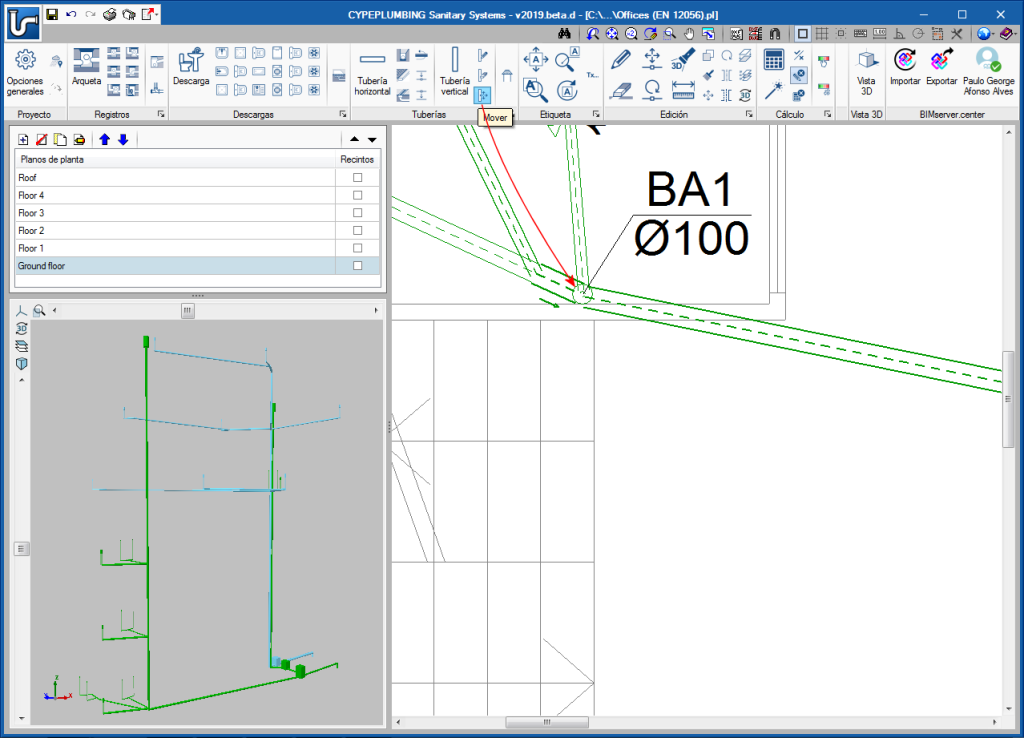

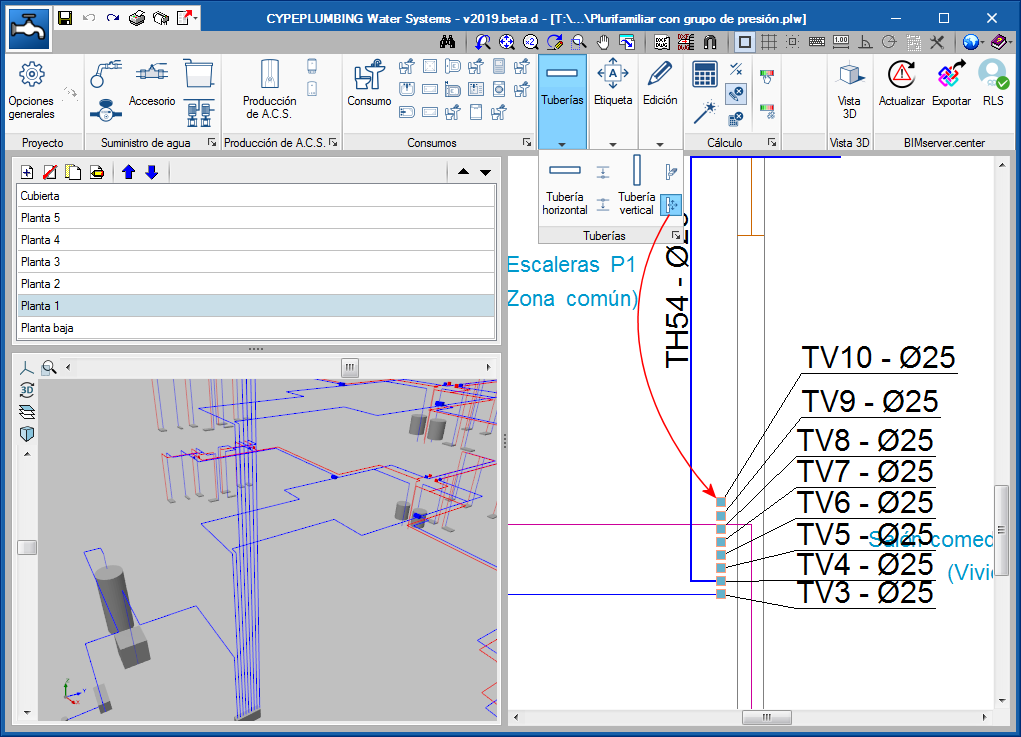

A new icon  has been added to the “Pipes” toolbar, which users can use to completely move a drainpipe, from its initial floor to the last. In previous versions, they could only be moved using the generic “Move” tool

has been added to the “Pipes” toolbar, which users can use to completely move a drainpipe, from its initial floor to the last. In previous versions, they could only be moved using the generic “Move” tool  from the “Edit” menu, which continues to exist to move any element. However, when this tool is used to move drainpipes, only the span of the pipe of the floor that is shown on-screen is moved.

from the “Edit” menu, which continues to exist to move any element. However, when this tool is used to move drainpipes, only the span of the pipe of the floor that is shown on-screen is moved.

In both cases, only the drainpipe is moved and not the horizontal pipes that connect to it.

The tool to move complete vertical drainpipes ( ) has also been implemented in CYPEPLUMBING Water Systems and CYPEPLUMBING Solar Systems.

) has also been implemented in CYPEPLUMBING Water Systems and CYPEPLUMBING Solar Systems.

has been added in the “Label” menu.

has been added in the “Label” menu.