Analysing, checking and designing

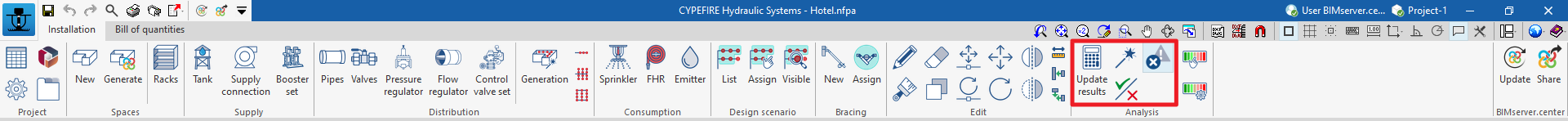

Within the "Installation" tab, in the "Analysis" group of the main toolbar, there are options for analysing, checking and designing the elements in the model:

The program uses the EPANET 2 analysis engine (developed by the Water Supply and Water Resources Division of the National Risk Management Research Laboratory) to perform the hydraulic analyses required for the design of sprinkler and fire hydrant networks. The use of EPANET allows an accurate analysis result to be obtained, valid for compliance with any of the codes available in the program or the configuration that is entered manually.

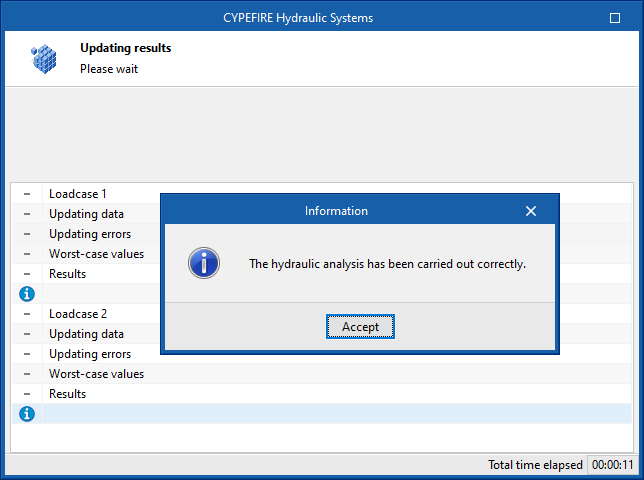

Update results

This will analyse the entered system according to the latest changes, including all design scenarios, update the calculated parameters in the elements and check if they are within the permitted ranges.

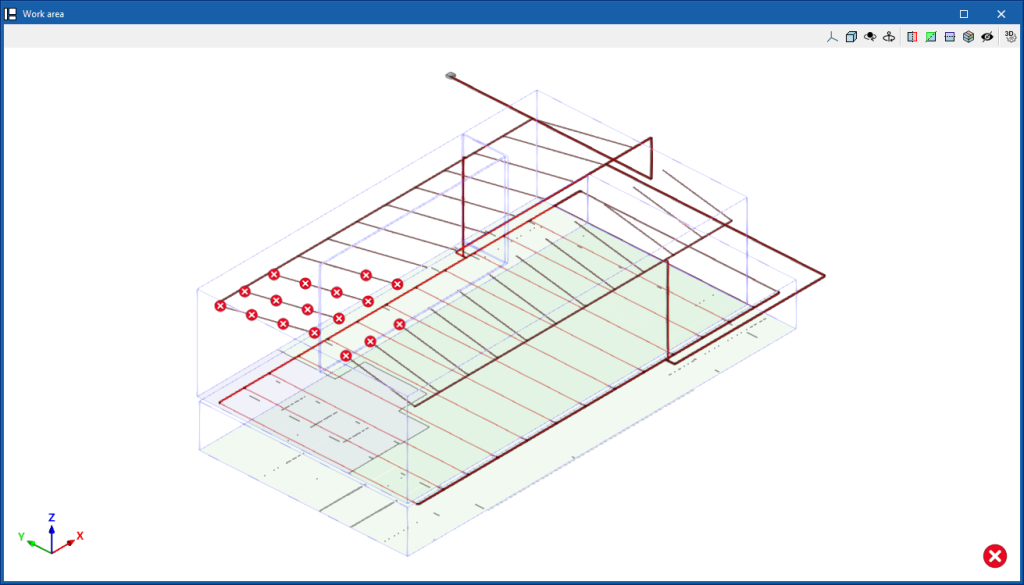

The result is a direct display with error or warning messages about the parts of the system that have a problem or fail a check, as well as the results and reports available after the analysis in the "Checks" section of the editing panel of the elements that have this feature.

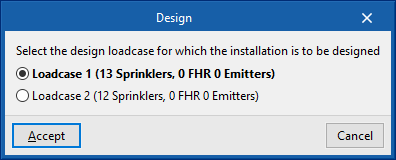

Design

Selects a design scenario and sizes the network accordingly, i.e. it automatically selects the pipe size.

In the editing panel of some elements such as tanks, the program also allows partial designs with the corresponding tool in the lower right-hand area.

The sizing tool can be configured from "Design criteria" under "General options". From this panel, the pipe diameters to be used in the design and the maximum number of sprinklers that each diameter can feed until jumping to the next diameter can be edited.

The "Design" tool will launch the diameter selection process and subsequently the hydraulic analysis. This selection and hydraulic analysis process shall be completed if no errors are found when comparing the results obtained with the requirements defined in the project options. Otherwise, the process shall be repeated until valid diameters are selected to comply with the selected standard or the defined configuration.

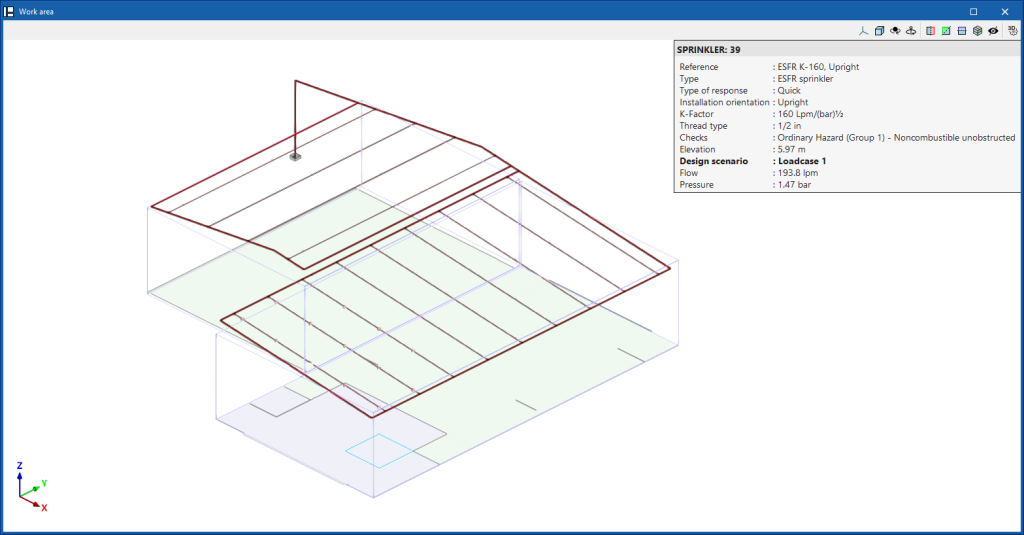

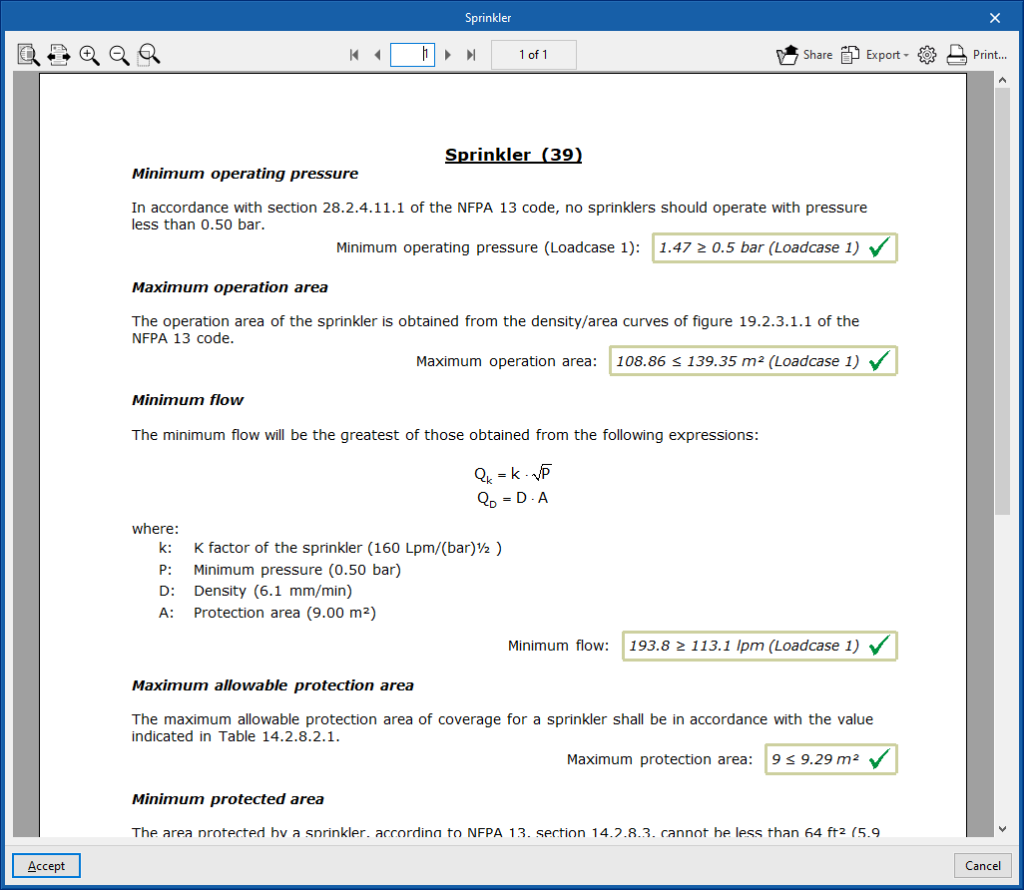

Consult checks

Consults the checks carried out in the last analysis performed on the job. After selecting the option, users can click on the elements in the system to directly access the list of checks carried out on the same.

If any changes have been made to the elements in the system, the "Update results" option must be used so that the program will update the results displayed.