In the search for a comfortable and healthy indoor environment, ventilation plays a key role. Controlled mechanical ventilation (CMV) is presented as a solution ready to ensure that the air quality in buildings and dwellings is pleasant. This type of system offers effective and controlled reinforcement in closed spaces that are not naturally ventilated.

What do we mean by controlled mechanical ventilation or CMV systems?

CMV is a forced ventilation system that controls the air flow inside buildings and dwellings to ensure maximum air quality. Unlike natural ventilation, which relies on external air currents, this system uses fans and a network of ducts to manage air flows and exchanges.

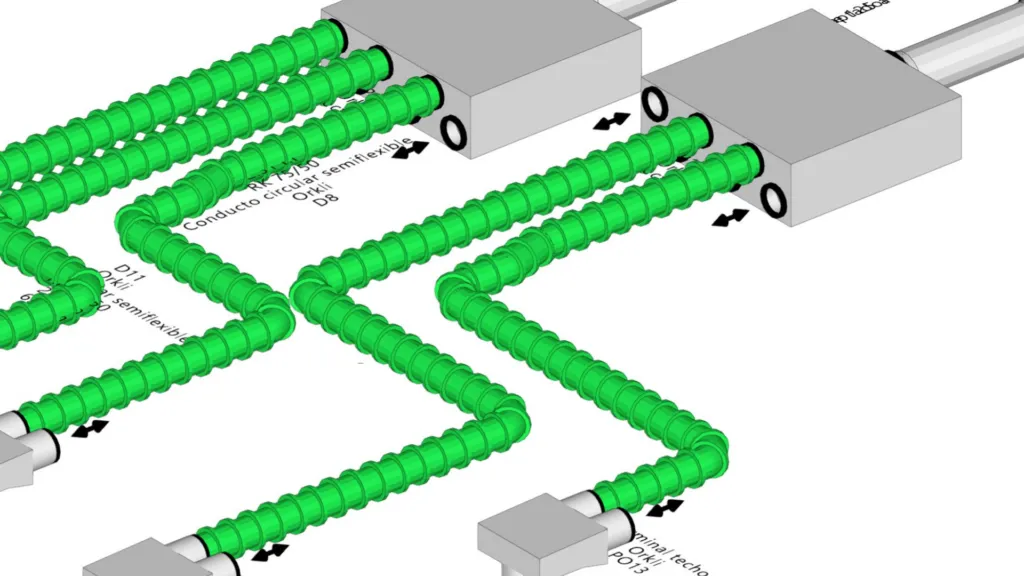

Thanks to two types of ducts, supply and exhaust valves, stale air is removed from areas such as bathrooms and kitchens and fresh air is brought into living areas such as living rooms and bedrooms, respectively. Therefore, these types of systems are very useful in very isolated buildings where natural air renewal may be limited, as they ensure a constant and controlled circulation of clean air at all times.

The importance of controlled mechanical ventilation

This system can improve indoor air quality, promote energy efficiency, increase thermal comfort and protect occupants' health. By effectively removing pollutants, dust, pollen and other allergens, CMV reduces CO2 concentration and excessive humidity, creating a healthier environment.

There are mainly two types of CMV systems: single-flow and dual-flow. Both manage energy consumption efficiently by renewing and adapting the indoor air temperature. However, dual-flow systems offer an additional advantage: they recover part of the heat from the extracted air to preheat the fresh air entering the building, thus maximising energy efficiency.

This indoor climate control not only maintains a constant temperature, but also reduces the risk of mould and dust mites, which improves the general well-being of the people living or working in the building.

To make the most of these advantages, it is important to have specialised design tools such as CYPEHVAC, which allow you to optimise the implementation of CMV systems.

Design CMV systems with CYPEHVAC and its new module

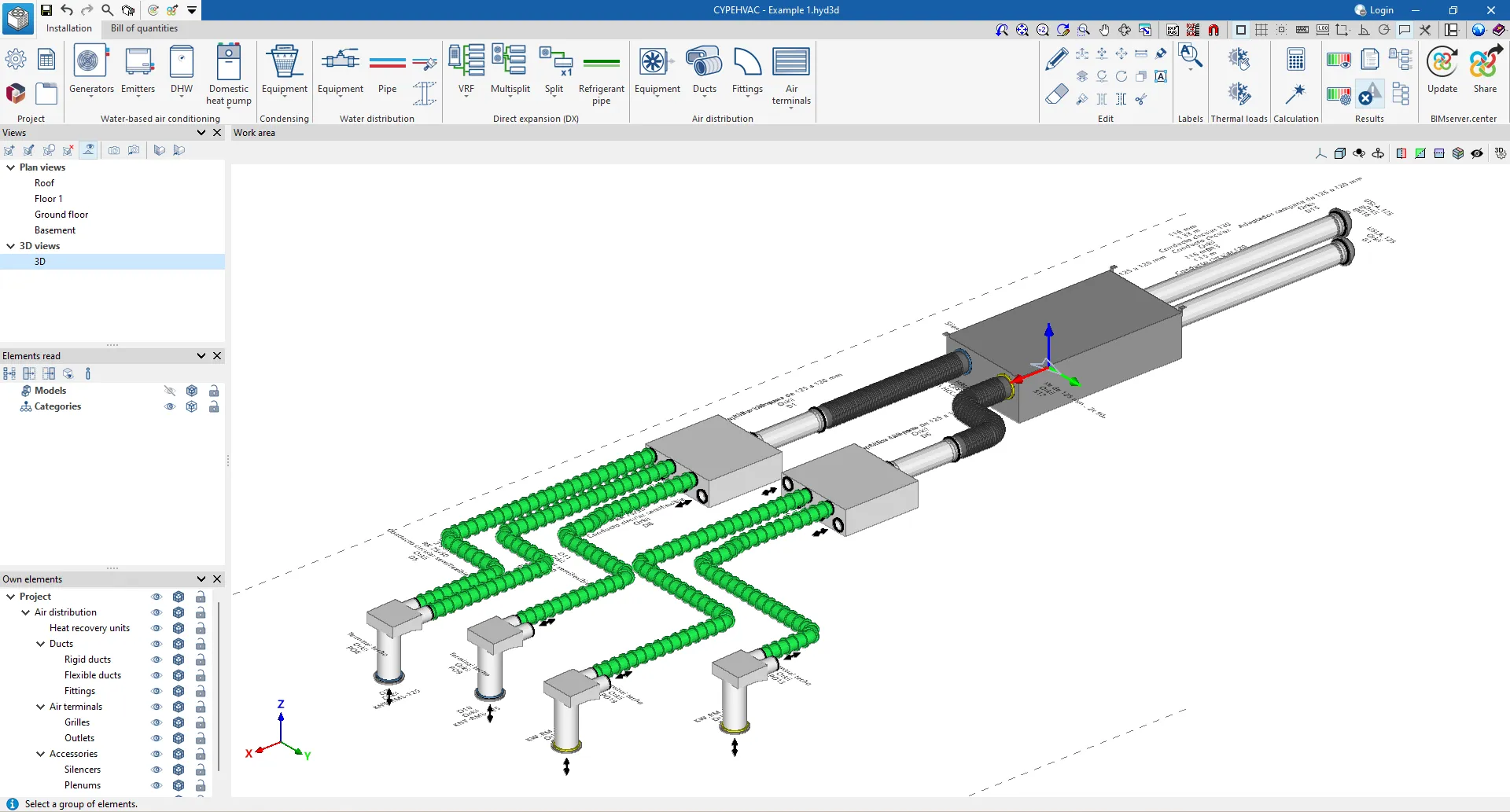

We are taking a step forward in the design of controlled mechanical ventilation systems by adding a new module for version 2025.d of CYPEHVAC. With this tool you will be able to include radiators, fan coils, boilers, heat pumps, ducted ventilation networks, heat recovery units, fans and air handling units. It also includes the possibility of importing the necessary information extracted from other Open BIM tools.

- Learn about all the new features in CYPE version 2025.d.

This update is an advance in the ability to analyse and design CMV systems, as it includes all the elements needed to create them, such as ducts, heat recovery units, plenums, supply and exhaust valves, and silencers.

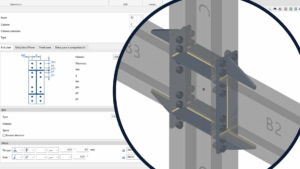

On the other hand, you will be able to select the supply and exhaust valves, which are mainly used in CMV systems, for the air terminals available in this tool. You can now select hoses and flow regulators compatible with each valve model, as long as the manufacturer's catalogue includes this information.

Elements can be entered using catalogues from different manufacturers, thanks to the connection to the Open BIM Database. This results in a precise selection of real components for each project.

Thanks to the implementation of the new module in CYPEHVAC and the integration of manufacturers' catalogues via the Open BIM Database, CYPE offers you a complete solution for the design of CMV systems. These tools provide professionals in the AEC industry with the necessary resources to create healthy and energy-efficient indoor environments.