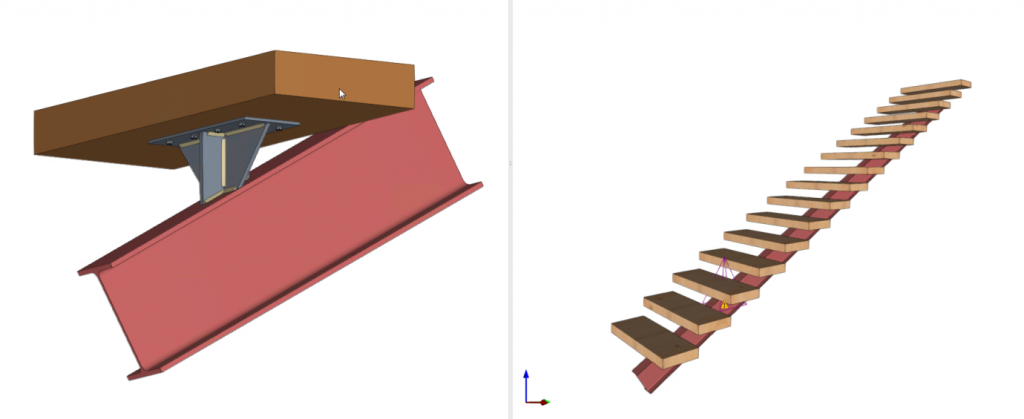

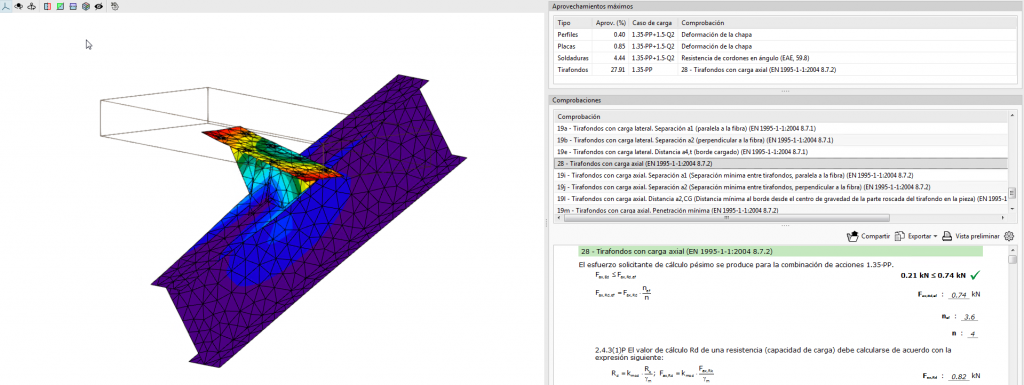

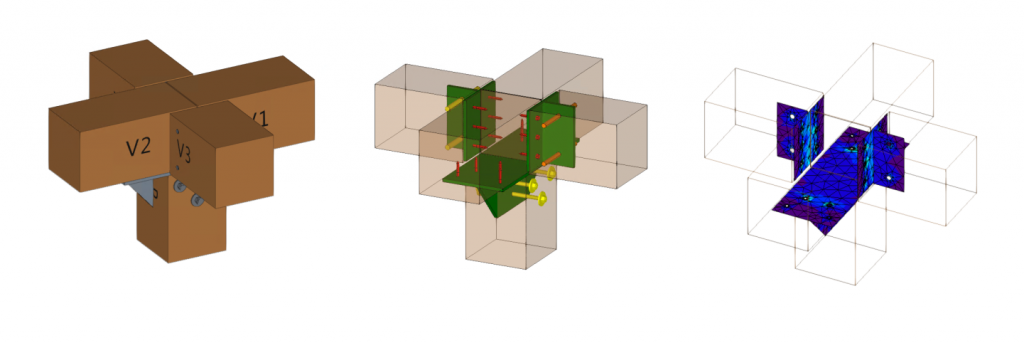

The CYPE Connect application for modelling and analysing connections for steel structures continues to improve and will incorporate a new feature in the coming weeks, thanks to which technicians will be able to design, analyse and verify steel-to-timber connections.

With this update, the software, available at BIMserver.center, goes a step further in offering state-of-the-art solutions to professionals working with structures in an Open BIM workflow; something becoming increasingly more important in the current context, where the use of timber in structures is increasing thanks to its benefits from an environmental point of view.

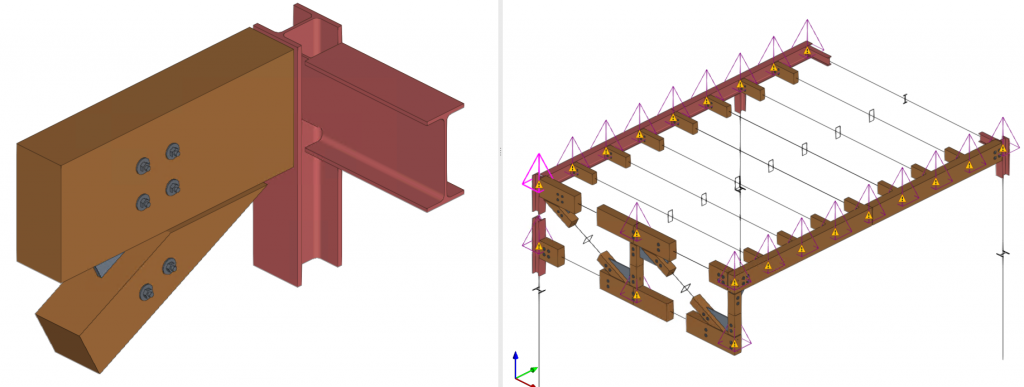

The new possibility for analyses offered by CYPE Connect will facilitate the work of technicians when it comes to solving the most complex part, which takes place during the joining of two or more elements in a timber structure and which requires, in the case of mechanical connections, mechanisms for coupling parts of the structure and transmitting forces.

The technological advances experienced by the construction industry and the use of timber as a structural material go hand in hand with this need to use different metal "fittings" adapted to each situation, thus requiring technicians to design customised connections or use prefabricated connections whenever possible.

Today, there are many new construction projects, including multi-storey buildings, where timber is becoming the structural material of choice. Overthrown by concrete during the real estate development boom, timber is now being presented as an alternative material that is sustainable over time, has a negative carbon footprint and is in line with Sustainable Development Goals (SDGs).

Furthermore, timber boasts a high degree of dimensional stability, structural capacity, lightness, quick assembly, and good energy performance, making it easy to adapt to different architectural styles and converting it into a popular material in industrialised construction.

New techniques, together with the development of industrial timber, the circular economy and the industry’s decarbonisation commitment have made timber construction a real alternative that requires solutions such as the one being implemented at CYPE Connect to facilitate safe and sustainable projects.

Different technical solutions for designing and analysing with structural timber

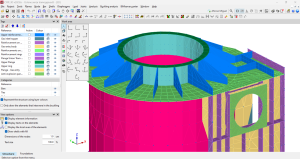

The new feature to be implemented by CYPE Connect for designing, analysing and verifying steel-to-timber connections is added to other technological solutions that CYPE has been incorporating in recent years to simplify project execution, both in new construction and refurbishment, that both use timber as a structural material.

More specifically, the CYPECAD structural design software includes the "Timber columns", "Timber joist floor slabs" and "Timber sections" modules, while StruBIM CYPE 3D allows, as well as the previous modules, the design of general three-dimensional structures based on timber bars.

The installations in Spanish, French and Portuguese have the option of drawing up bills of quantities, technical specifications, life cycle analysis, waste management and other information. The Price Generator contains different sections that meet the needs of technicians in the following areas:

- Structural sawn timber: Structural sawn timber is timber that is specifically graded for structural use, the species and origin of which has its mechanical properties determined by standardised testing.Structural glued laminated timber: Popularly known as glulam, is a manufactured timber product. It is made by bonding together individual laminates (layers) of solid timber boards with durable, moisture-resistant structural adhesives. The laminates of timber boards are layered and glued together so that the direction of the grain of each board runs parallel with the longitudinal axis of the member being fabricated. The laminating process allows a single, large structural member to be manufactured by laminating a number of smaller pieces of timber. All manufactured beams have the same physical properties, which makes it possible to adjust the calculations more precisely than with the use of solid wood.

- Timber frames: It describes a system of panelised structural walls and floors constructed from small section timber studs, clad with board products, in which the timber frame transmits vertical and horizontal loads to the foundations.

- Structural Cross Laminated Timber or CLT: Cross-laminated timber panels are produced having an odd number of layers of softwood planks laid on top of each other perpendicularly at right angles and glued together under pressure.

- Straw bale construction: Building method that uses bales of straw as structural elements with a separate, load-bearing structural frame, typically made from timber. Only assembly is required at the construction site with this prefabricated timber and straw panels. This way, all the panels fit together perfectly and, using dry construction, the entire building can be assembled in a very short time compared to traditional constructions.