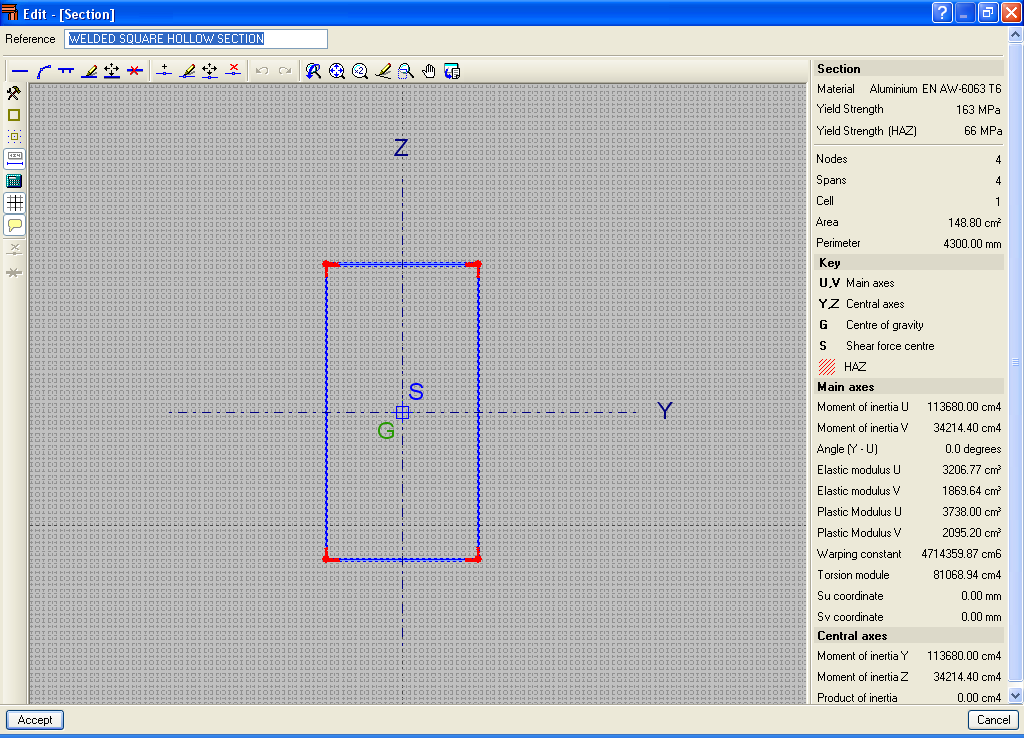

In this new version, aluminium sections requiring longitudinal welds can now be introduced in the Special aluminium sections editor. The program checks these sections taking into account the reduction of the resistance properties which arise in areas close to these welds: where the elastic limit of the material is affected significantly. The softened zone is referred to as the HAZ (heat affected zone), its extent and severity are calculated by the program.

Update history

CYPE 3D

Heat affected zones

- Published on

- 2012.a

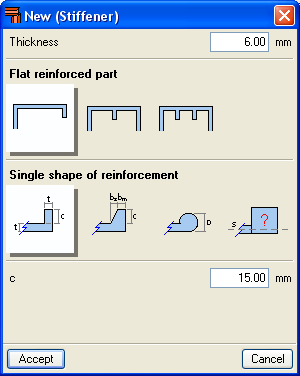

Automatic calculation of the susceptibility to local buckling due to compression

In previous versions of the program, the automatic calculation of the susceptibility to local buckling due to compression was already included assuming that each of the flat elements making up the section buckled in an isolated manner (independent from the rest), and the possibility was included, for any other type of buckling other than the individual type to be considered, to modify the local buckling coefficient which affects the slenderness parameter associated to each element. In this new version, the automatic calculation of the susceptibility to local buckling due to compression considering the possibility that several elements can buckle together as if they were a single element, is also included, hence combined buckling modes are obtained. The program is able to detect and analyse the buckling in a group of elements in the following cases:

- Element sequence with all their ends aligned along a straight line

- Element sequence with all their ends arranged along a circumference arc with small curvature

- Element sequence making up a cell

The combined buckling is also studied if the elements making up the section have been stiffened, which is commonly referred to as buckling due to distortion. Regarding the stiffened elements, a new assistant has been implemented for the design with standard reinforcement in accordance with that exposed in EC9.

- Published on

- 2012.a

New codes for the Joints modules

The following rolled steel codes have been implemented for the five joints modules (Joints I, Joints II, Joints III, Joints IV and Joints V):

- ANSI/AISC 360-05 (LRFD) (USA – International )

- IS 800: 2007 (India)

- Published on

- 2012.a

Code implementation. NCh433.Of1996 Modified in 2009 (Chile)

NCh433.Of1996 Modified in 2009 (Chile). Official Chilean Code. Seismic Design of Buildings.

Implemented in CYPECAD and Metal 3D. Includes the emergency modifications presented in the Decree Nº117 (V. and U.) of the Diario Official de Chile of the 14th February 2011.

- Published on

Code implementation. NSR-10 (Colombia)

NSR-10 (Colombia): Reglamento Colombiano de Construcción Sismo Resistente

Code implemented in CYPECAD and Metal 3D.

The NSR-10 code substitute the outdated NSR-98 code. Nonetheless, any of the two codes can be used in CYPECAD and Metal 3D.

- Published on

- 2011.d

Code implementation. IS 456: 2000 (ACI 318M-08) (India)

- IS 456: 2000 (ACI318M-08) (India): Plain and Reinforced Concrete – Code of Practice.

Implemented in CYPECAD and Metal 3D.

Includes materials, steel bar diameters and load combinations of the code with the design criteria of the ACI 318M-08 (USA) code. The design criteria of the IS 456: 2000 code will be included in upcoming updates of the 2011 version.

- Published on

- 2011.d

Code implementation. CFE 2008 (Mexico)

CFE 2008 (Mexico): Manual de diseño de Obras Civiles. Diseño por sismo. Comisión Federal de Electricidad. México 2008.

Code implemented in CYPECAD and Metal 3D.

- Published on

- 2011.c

Code implementation. DIN 18800:2008-11 (Germany)

DIN 18800:2008-11 (Alemania): Deutsches Institut für Normung. Stahlbauten.

Code implemented in CYPECAD and Metal 3D for the following sections:

Rolled and welded steel

- I

- C

- L

- Rectangular hollow section

- Circular hollow section

Cold-formed steel

- C and stiffened C

- L and stiffened L

- Rectangular hollow section

- Circular hollow section

- Published on

- 2011.c

Export to Tekla® Structures

The following elements have been implemented when exporting to Tekla structures:

- Concrete beams and columns of CYPECAD, and concrete bars of Metal 3D and integrated 3D structures of CYPECAD. The elements that are exported have rectangular, circular, T or L sections.

- Special extruded aluminium sections

- Trims at hollow section ends processed by the new Joints V module.

These elements are exported as macros type “Tube-Saddle+Hole” for versions 15.0 SR1 and 16.0 of Tekla Structures.

- Published on

- 2011.a

Faster seismic analysis

An optimisation in the analysis procedure now reduces the time taken to analyse structures with applied earthquake loads.

- Published on

- 2011.a

Ties

Metal 3D has incorporated the possibility to define Ties between nodes. The ties between the nodes are used to indicate that two or more nodes have the same displacements for all the loadcases. This displacement can be in one, two or three directions in accordance with the X, Y and Z global axes. The number corresponding to each group of nodes whose displacements have been tied is displayed on screen.

Bear in mind that for two or more nodes to have the same displacement, an element or construction arrangement must be present in the structure that will effectively materialise the equal displacement hypothesis.

Ties cannot be assigned to nodes that form part of braced frames when the tied displacement has its projection on the plane of the braced frame.

- Published on

- 2011.a

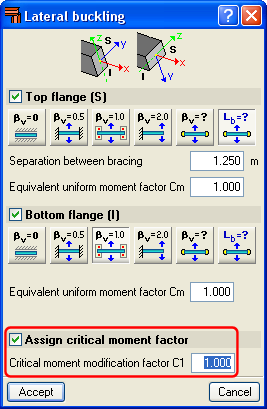

Improvements in the definition of lateral buckling moment coefficients

- Published on

- 2011.a