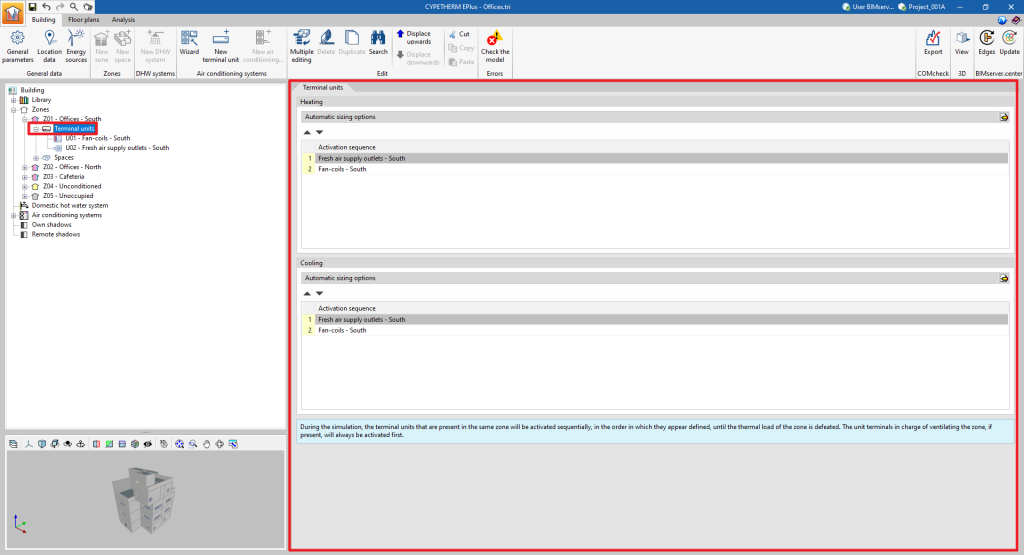

Terminal unit management. Activation sequence and automatic sizing options

The "Terminal units" panel can be used to manage the operation of the terminal units defined in each zone and to define the EnergyPlus™ automatic sizing options.

Activation sequence

During this simulation, the terminal units in the zone are activated sequentially until the thermal load of the zone is overcome, according to the order defined in the "Activation sequence" sections, distinguishing between "Heating" and "Cooling".

The terminal unit responsible for the zone ventilation, if present, is always activated first.

Automatic sizing options

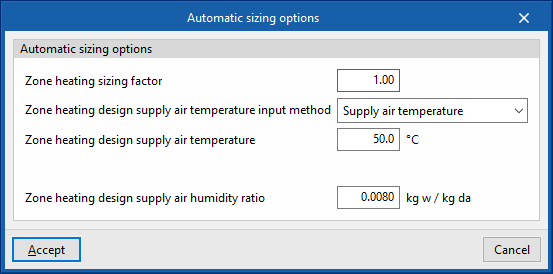

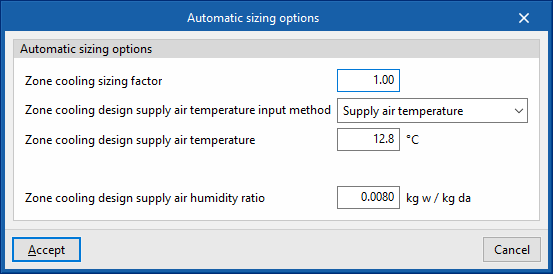

The automatic heating/cooling sizing options are advanced features that allow users to edit the parameters that EnergyPlus™ uses to determine the characteristics of the HVAC units that have not been specified by the user (autosize function):

- Zone heating sizing factor/Zone cooling sizing factor

The scaling factor on the calculated thermal load in the zone. The capacity of the air-conditioning units is determined by the thermal load of the zone multiplied by this factor. - Zone heating design supply air temperature input method/Zone cooling design supply air temperature input method

The air flows that the units must deliver to overcome the thermal load are calculated based on a user-defined design supply temperature. Three options are available:- Supply air temperature

The design supply air temperature for heating/cooling must be defined. - Temperature jump

The temperature difference between supply air and zone temperature must be defined. - System supply air temperature

This is only valid if the zone is connected to an all-air system. The "supply air temperature" shall be taken as the supply air temperature defined as the cooling/heating design supply temperature on the panel of the air handling unit of the all-air system.

- Supply air temperature

- Zone heating design supply air humidity ratio/Zone cooling design supply air humidity ratio

Sizing factor:

The zone sizing factor multiplies the zone demand on the design day to obtain the power of the air conditioning units.

For example, if there are two radiators in a heating zone and their power has not been specified, when the simulation starts, EnergyPlus™ calculates that the heating demand of the zone on the design day is equal to 1000W. In this case:

- If the "Zone heating sizing factor" equals 1, EnergyPlus™ assigns a power of 1*1000=1000 W to each radiator. In total, there will be an installed power in the zone equalling 2000 W. This means that effectively only one of the radiators is switched on, as it is already sufficient to meet the heating demand.

- If the "Zone heating sizing factor" equals 0.5, EnergyPlus™ assigns a power of 0.5*1000=500 W to each radiator. In total, there will be an installed power in the zone equalling 1000 W. The radiators will be switched on consecutively: the first one will be switched on to deliver a power of up to 500 W and, if the heating demand of the zone is higher, then the second one will be switched on.

For example, if there are two radiators in a heating zone and their power has not been specified, when the simulation starts, EnergyPlus™ calculates that the heating demand of the zone on the design day is equal to 1000W. In this case:

- If the "Zone heating sizing factor" equals 1, EnergyPlus™ assigns a power of 1*1000=1000 W to each radiator. In total, there will be an installed power in the zone equalling 2000 W. This means that effectively only one of the radiators is switched on, as it is already sufficient to meet the heating demand.

- If the "Zone heating sizing factor" equals 0.5, EnergyPlus™ assigns a power of 0.5*1000=500 W to each radiator. In total, there will be an installed power in the zone equalling 1000 W. The radiators will be switched on consecutively: the first one will be switched on to deliver a power of up to 500 W and, if the heating demand of the zone is higher, then the second one will be switched on.