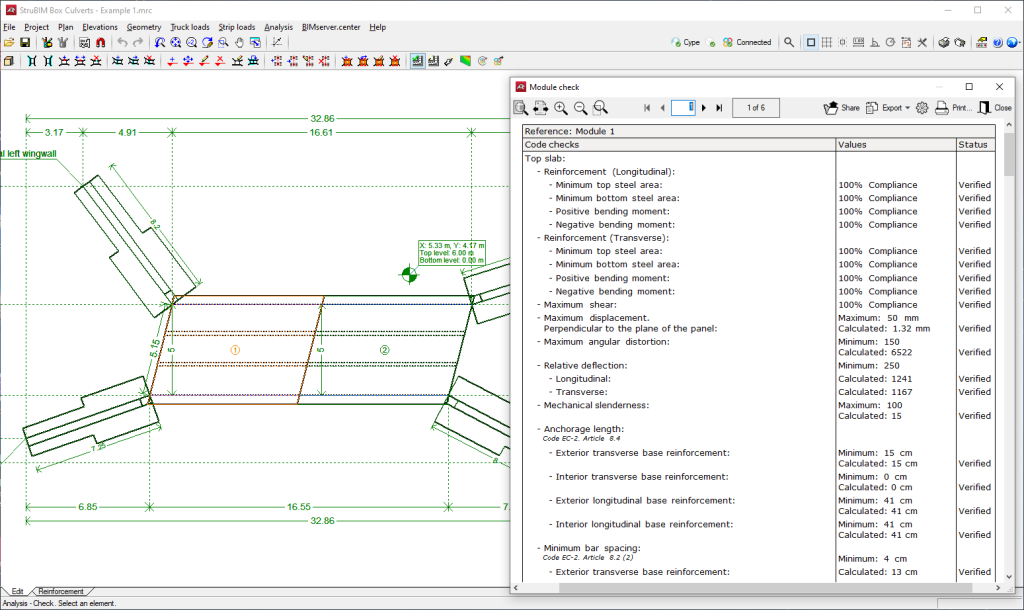

Design and checking

Designs and checks all box culvert elements: top and bottom slab, intermediate cell walls and lateral walls, and wing walls (wall and footing), obtaining the reinforcement for all of them.

Checks the angular distortion in the top slab, bottom slab, lateral walls and dividing walls.

The reinforcement of any selected part of the box culvert can be consulted or edited.

The reinforcement and dimensions of the wall and the wing wall footing can be modified and then checked.

Modules

In each module, eight stresses are obtained through elastic and linear analysis to verify and design the concrete section and reinforcement. Displacements are used to check deflections, stresses on the soil and the detachment of the foundation slab, among others.

The checked states are:

- Minimum geometric reinforcement ratio

In order to control the cracking due to deformations caused by temperature and shrinkage, minimum reinforcements ratios are applied, which vary according to each standard. - Minimum mechanical reinforcement ratio

Minimum mechanical reinforcement ratios are required to prevent brittle failure when the section cracks due to bending moment stresses. - Bending moment check

The structural check of the cross-section is carried out using the simplified parabolarectangle stress-strain diagram as the constitutive law of concrete, which is suitable for delimiting the bending moment rupture stress zone from the non-rupture zone of a reinforced concrete cross-section. The bending moment verification is implemented for all standards supported by the program, with specific considerations for stress integration in the cross-section and the pivots that define the maximum allowable deformations for the materials constituting the cross-section (steel and concrete). For the bending moment check, the reinforcement must be anchored in order to be considered effective in the bending moment analysis. Furthermore, as bending moment stresses act simultaneously with shear stresses, there is an interaction between them. This phenomenon is considered by shifting the bending moment law by a certain distance in the most unfavourable direction. - Shear check

This ultimate limit state is checked in the same way as the bending moment. Since there is no transverse reinforcement in the cross-section, only the contribution of concrete to shear resistance is considered. The contribution of concrete to shear stress is evaluated using the experimental term Vcu. This term is usually included in the tensile fatigue shear check of the cross-section’s web. Various expressions for evaluating the Vcu component have been considered based on the chosen standard. - Maximum displacement and relative deflection

The displacements and deflection for structural elements are limited according to the applicable standard. - Angular distortion

The angular distortion generated in the top slab, bottom slab, lateral walls, and dividing walls, is considered as a serviceability limit state (SLS). - Slenderness ratio

The maximum slenderness of compressed elements, such as lateral walls and module slabs, is limited. - Minimum anchorage hook length

Calculations are carried out in compliance with the various implemented standards. - Minimum reinforcement spacing

The minimum spacing between reinforcement bars according to standards is required in order to allow the concrete to be poured correctly. - Maximum reinforcement spacing

This limit is set to ensure that there are no areas without reinforcement. This is a minimal condition for distinguishing between “reinforced concrete” and “mass concrete”. - Uplift

A check is carried out to verify that there is no upward vertical displacement at any node in the foundation slab, as this would invalidate the analysis (the soil cannot pull the slab). If this occurs, the structure should be checked, by stiffening the slab if possible. - Allowable bearing pressure

The maximum bearing pressure that can be applied to the soil is limited to the value specified by the user.

Wingwalls

The states to be checked are as follows:

- Check for joint shear at base of wall/span

The calculated shear at the joint between the wingwall elevation and the footing is checked to ensure that it is less than what the section can withstand at that point, considering the concrete cross-section and the steel provided. - Minimum thickness

The minimum thickness is restricted according to the standard’s requirements. - Minimum geometric ratio

Minimum reinforcement ratios are imposed to control cracking due to deformation caused by temperature and shrinkage and vary according to each standard. - Minimum mechanical ratio

For vertical reinforcements, minimum mechanical ratios are required to prevent brittle failures when the section cracks due to bending momentum stresses. - Maximum geometric ratio

A maximum ratio is imposed on the total vertical reinforcement. - Minimum reinforcement spacing

The minimum spacing between reinforcement bars according to standards is required in order to allow the concrete to be poured correctly. - Maximum reinforcement spacing

This limit is established to ensure that there are no areas without reinforcement. This is a minimal condition for distinguishing between “reinforced concrete” and “mass concrete”. - Bending moment check

The structural check of the cross-section is carried out using the simplified parabolarectangle stress-strain diagram as the constitutive law of concrete, which is suitable for delimiting the bending moment rupture stress zone from the non-rupture zone of a reinforced concrete cross-section. The bending moment verification is implemented for all standards supported by the program, with specific considerations for stress integration in the cross-section and the pivots that define the maximum allowable deformations for the materials constituting the cross-section (steel and concrete). For the bending moment check, the reinforcement must be anchored in order to be considered effective in the bending moment analysis. Furthermore, as bending moment stresses act simultaneously with shear stresses, there is an interaction between them. This phenomenon is considered by shifting the bending moment law by a certain distance in the most unfavourable direction. - Shear check

The ultimate limit state is checked in the same way as the bending moment. As there is no transverse reinforcement in the section, only the contribution of concrete to shear resistance is considered. The value of the concrete contribution to shear stress is evaluated using the experimental term Vcu. This term is usually included in the tensile fatigue shear verification of the section’s web. Various expressions for evaluating the Vcu component are considered based on the chosen standard. - Cracking check

The cracking limit state is a Serviceability Limit State (SLS) that is checked to control the appearance of cracks in the concrete structures. Crack control is crucial for walls as it occurs primarily on the backfill face. This is an area where the reinforcement corrosion is likely to proliferate and where it cannot usually be observed. Deterioration of the structure can occur without the negative effects on the wall being clearly visible. The cracks caused by actions directly acting on the wall (soil, water table, surcharges, etc.) should be controlled, rather than the cracks caused by shrinkage and temperature, which are already taken into account when considering geometric minimums.

A simplified process in simple bending has been followed to calculate the limit crack opening, which provides safer results than those that can be obtained by applying bending moment methods.

The general crack opening method is followed for the different standards applied in the program. The results obtained are compared with the limits imposed by each standard, according to the type of exposure or environment in which the structure is located.

Unlike the ultimate limit states of bending moments and shear, in which the combination of actions related to the ultimate limit states are used, in the case of cracking, the combinations of actions related to the characteristic actions are applied. The program works by calculating the characteristic crack opening for all the loadcases.

The calculation is repeated at different screen heights in the same way as for the bending moment and shear checks. The most unfavourable value is extracted and StruBIM Box Culverts – User’s Manual / 12 compared with the limit crack opening indicated by each standard. This way, it is possible to determine whether or not the Serviceability Limit State (SLS) is met. - Lap splice length check

The lap splice length check analysis is carried out according to the different implemented standards. - Base reinforcement crown anchor check

- The anchor length analysis is carried out according to the different implemented standards.

Wingwall footings

The load on a wall is converted into a load distribution along the wall in a discrete way. This is like transforming a resultant force into a stress distribution applied along the base of the wall, discretised into steps that the program calculates internally according to the dimensions.

The states to be checked are the following:

- Overturning/Sliding stability check

By applying the corresponding limit state combinations, the resultant is checked to ensure that it lies within the footing, and the stability coefficient for overturning and sliding is calculated. - Soil bearing pressures A plane strain deformation assumption is made for the footing, so that, depending on the stresses, trapezoidal-shaped soil bearing pressure will be obtained. Traction is not allowed, therefore, if the resultant force falls out of the central core, unstressed areas will appear. The resultant must lie within the footing; otherwise, there would be no equilibrium. The self-weight of the footing is considered. The average stress is checked to ensure that it does not exceed that of the soil and that the maximum edge stress does not exceed the average stress by more than 1%.

- Minimum depth

The minimum depth specified by the corresponding standard is checked. Anchor length The anchors at the ends of the reinforcements are checked, placing the corresponding hooks as necessary and according to their position. - Minimum bar diameter

The diameter is checked to ensure that it does not exceed the minimum specified in the standard. - Maximum bar spacing

This limit is established to ensure that there are no areas without reinforcement. This is a minimal condition for distinguishing between “reinforced concrete” and “mass concrete”. - Minimum bar spacing

Minimum spacing between reinforcements specified by the standard are checked. - Footing bending

The footing bending is checked with the reference section located at 0.15 times of the wall dimension towards the interior. Bending design is needed to provide adequate depths to avoid the need for compression reinforcement. If tractions appear in the top face of the footing, upper reinforcements will be inserted. - Shear

The reference section is placed at a useful depth of the wall edges. Shear design makes it necessary to provide adequate depths to avoid the need for transverse reinforcement. - Geometric and mechanic reinforcement ratio

Compliance with the minimum mechanical and geometric reinforcement ratios specified in the standard is checked.

Codes available in the program

The concrete codes implemented in the StruBIM Box Culverts program are the following:

| Codes: |

|---|

| The wide range of codes included in the CYPE programs can be found at this link. |

| Best practice: |

|---|

| To change the codes applied in the program, select the ‘Codes’ button available in the globe icon in the top right-hand corner of the program. |