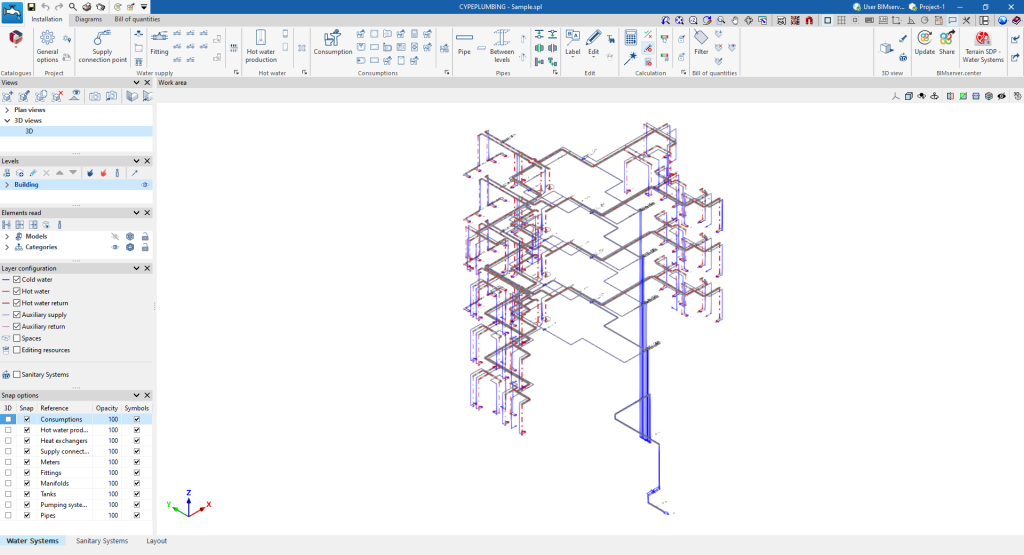

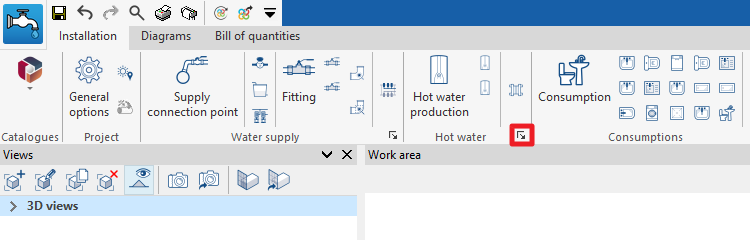

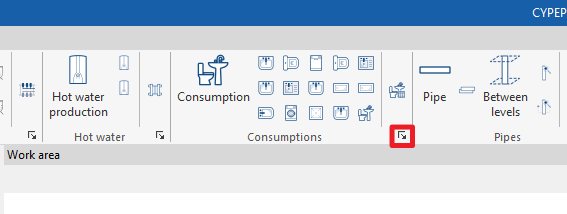

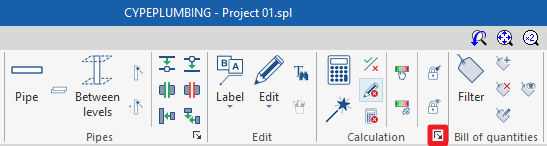

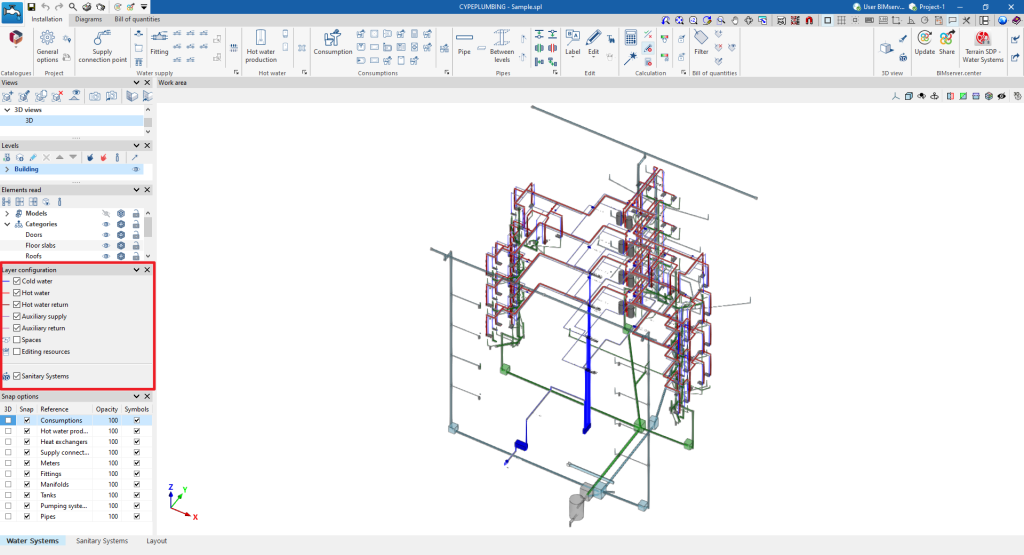

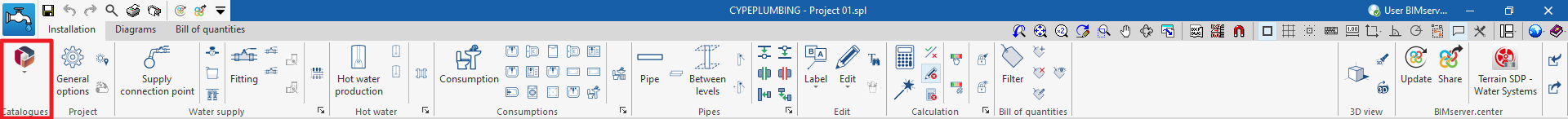

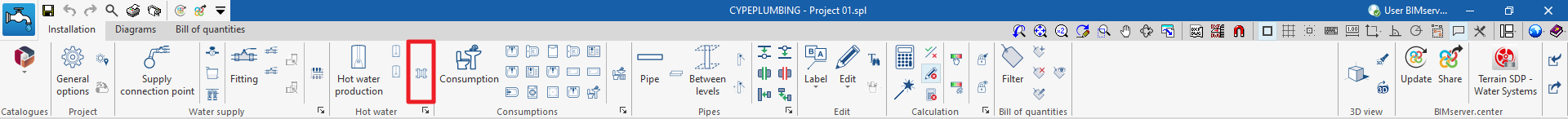

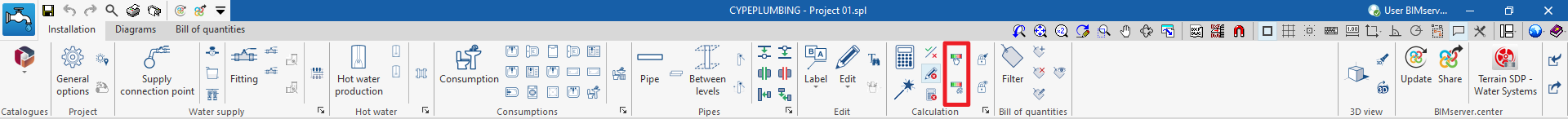

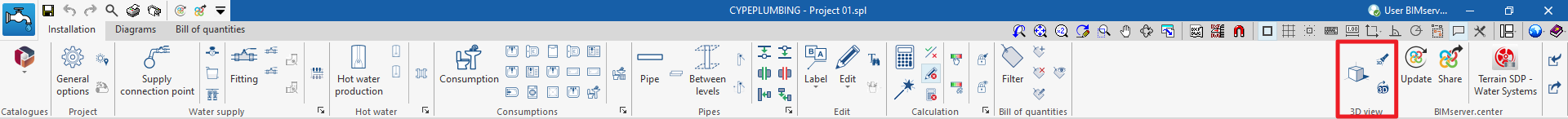

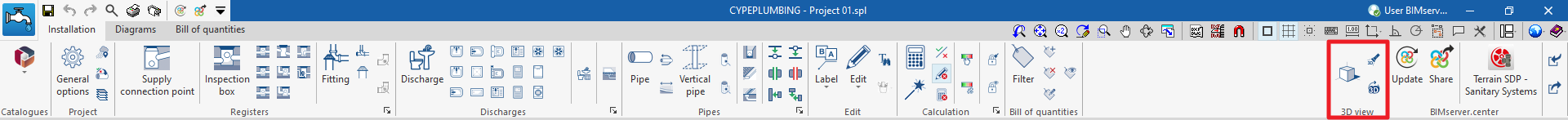

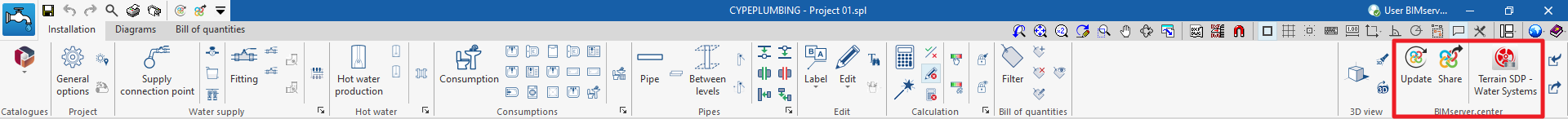

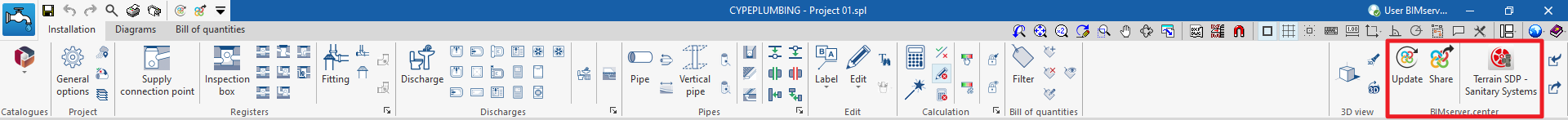

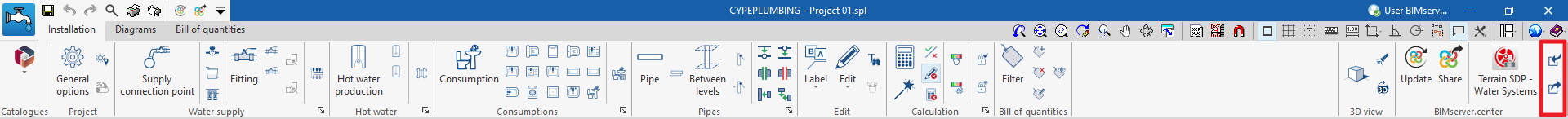

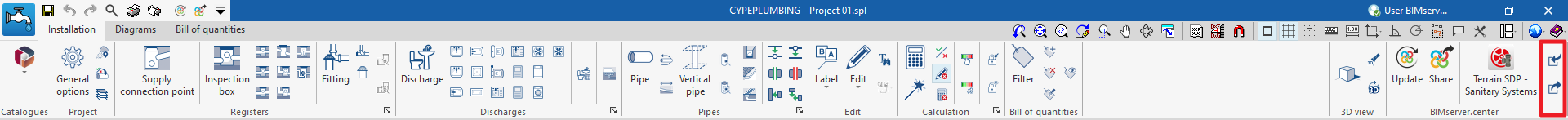

CYPEPLUMBING. "Water Systems" tab

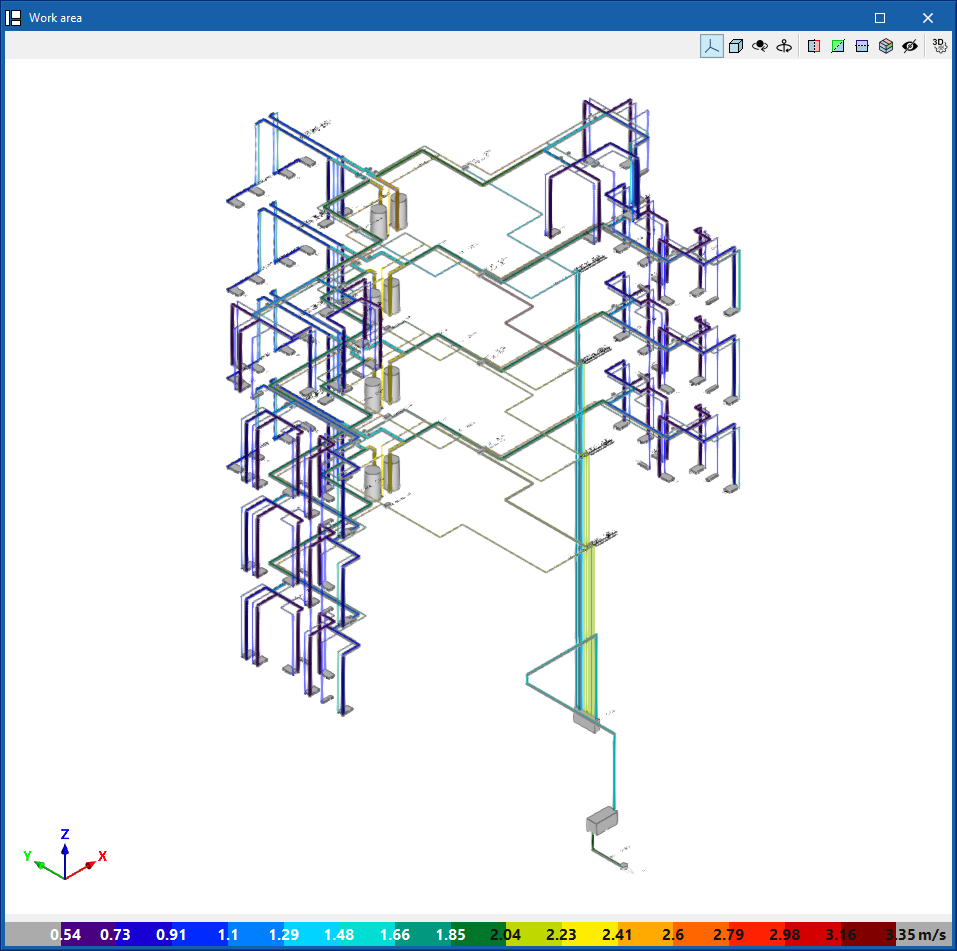

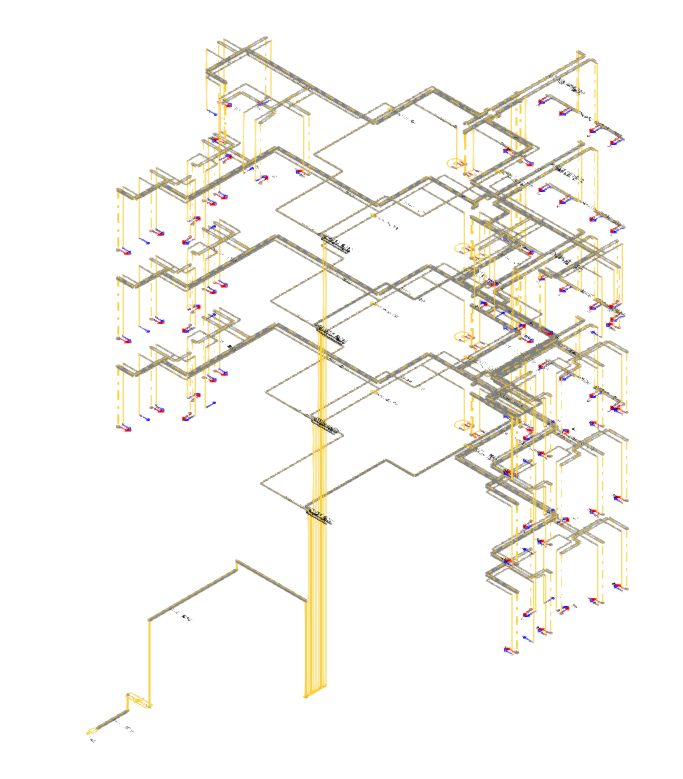

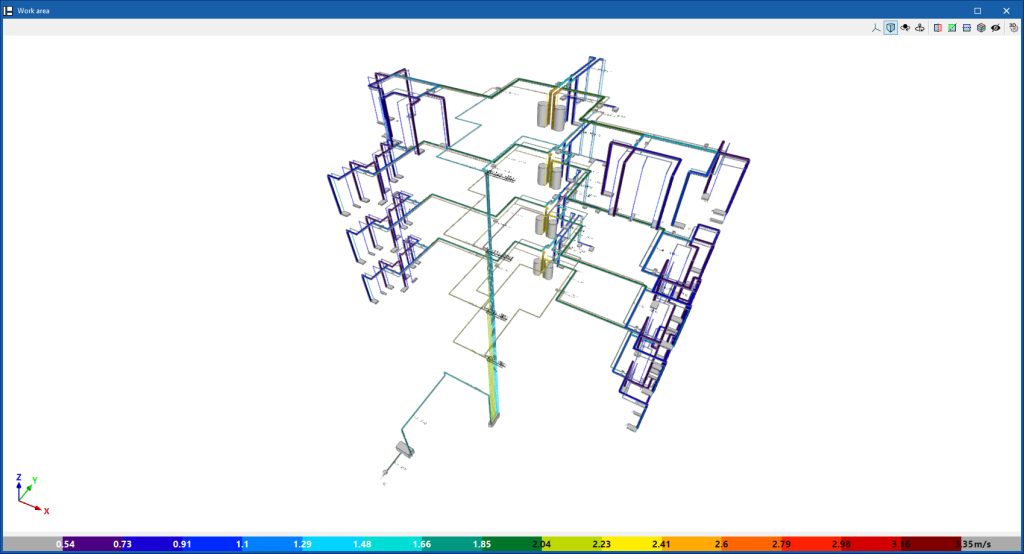

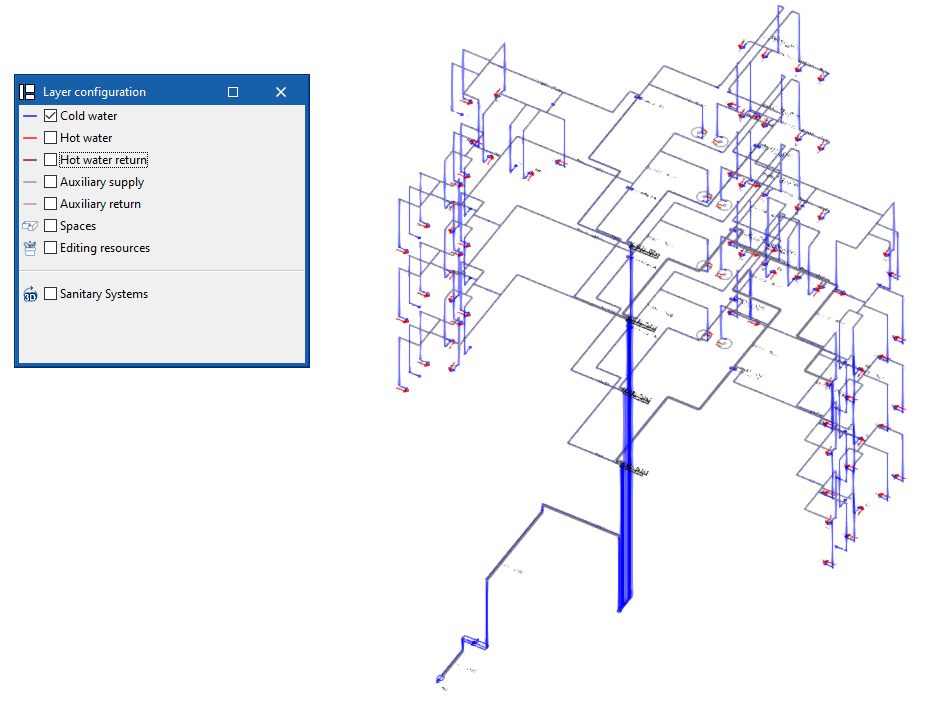

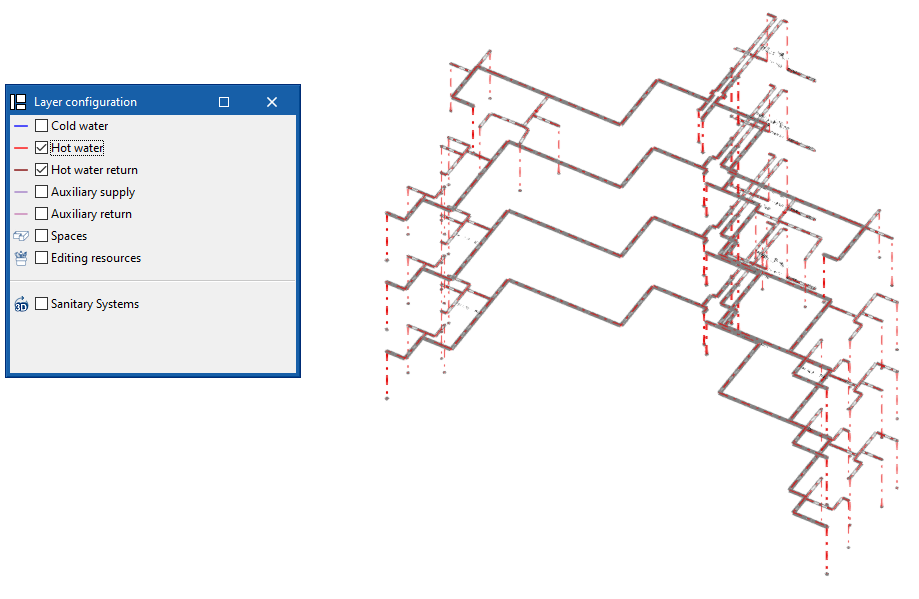

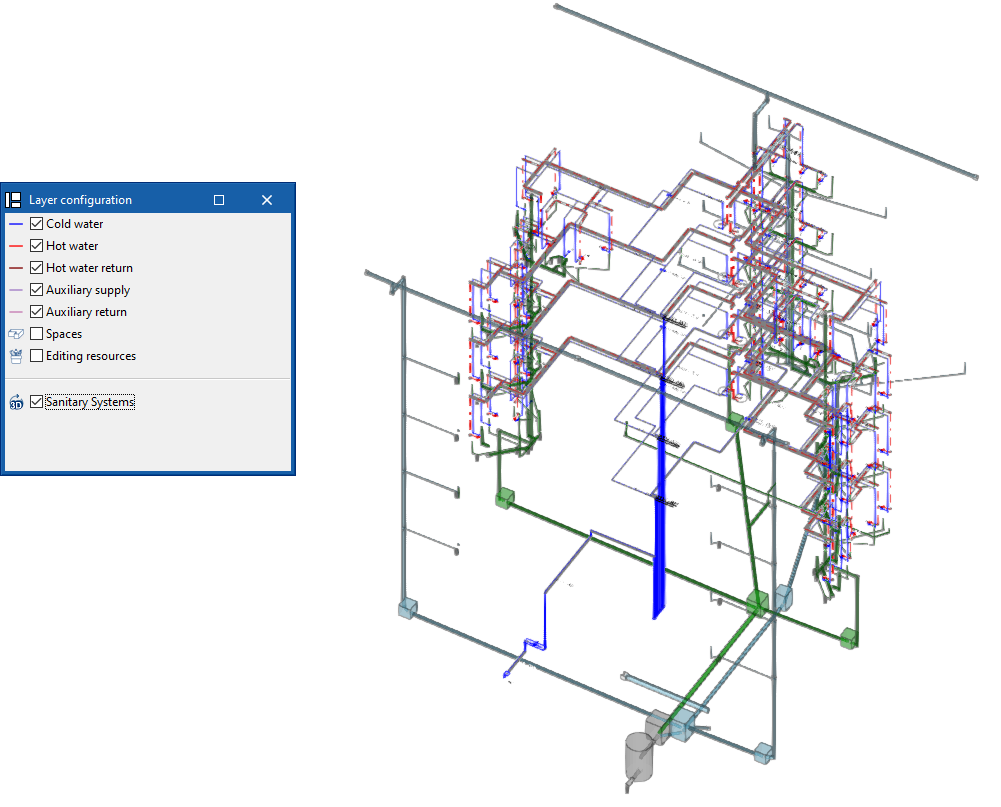

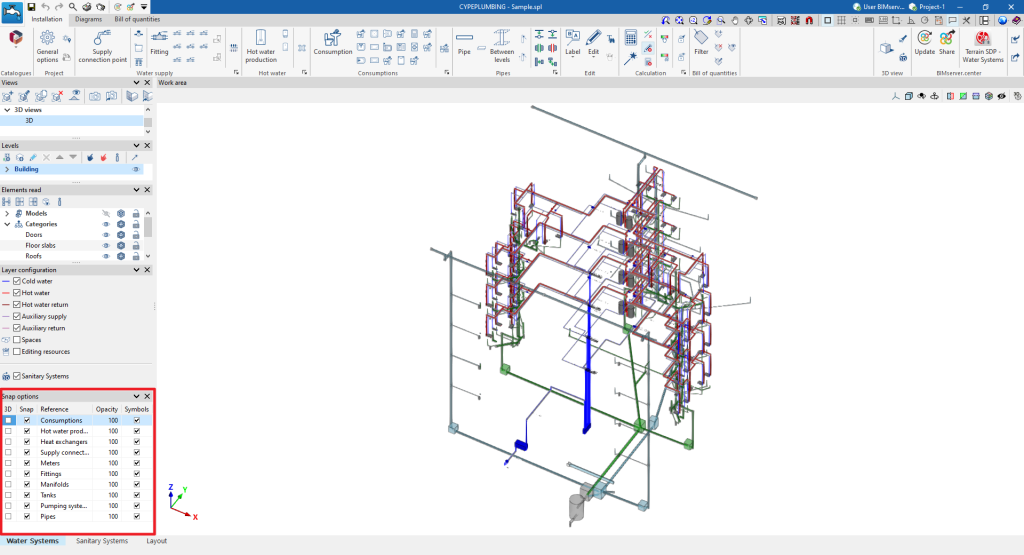

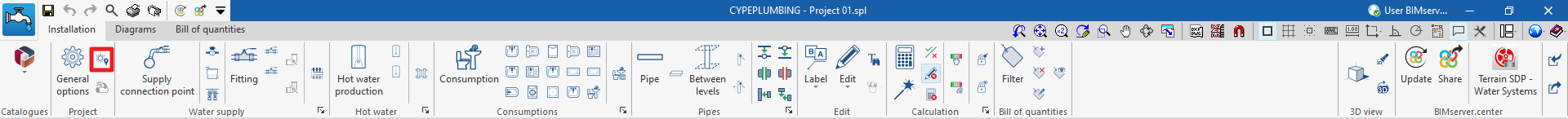

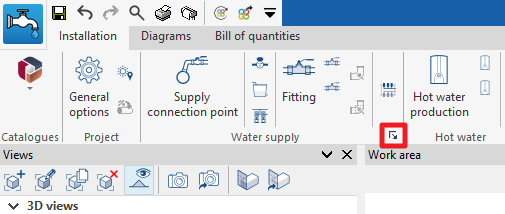

Work environment of the "Water Systems" tab

The interface of the "Water Systems" tab of the CYPEPLUMBING program has three tabs at the top with different work environments: "Installation", "Diagrams" and "Bill of quantities". These environments are similar to those in other CYPE tools and have a system of dockable windows that can be customised to adapt the workspace to the project's needs.

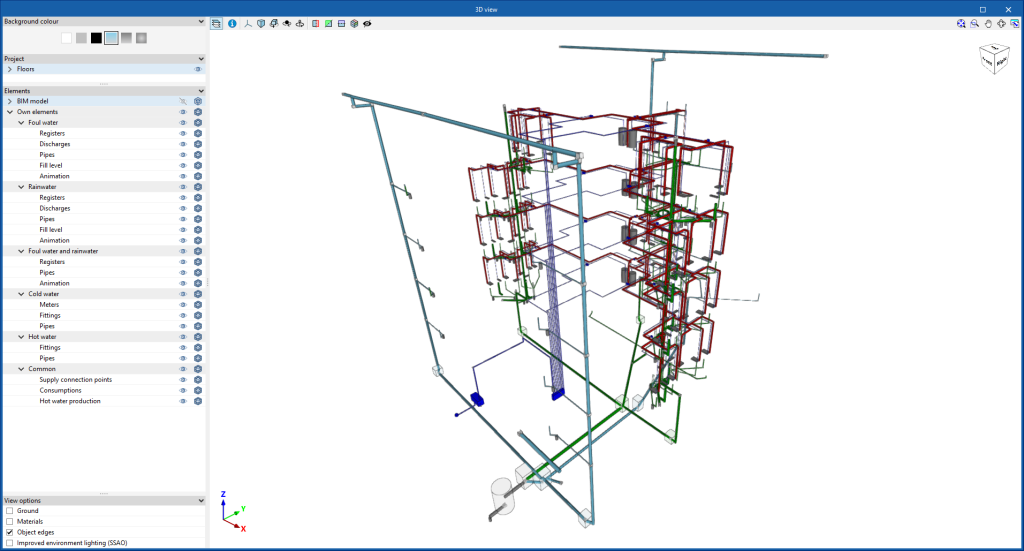

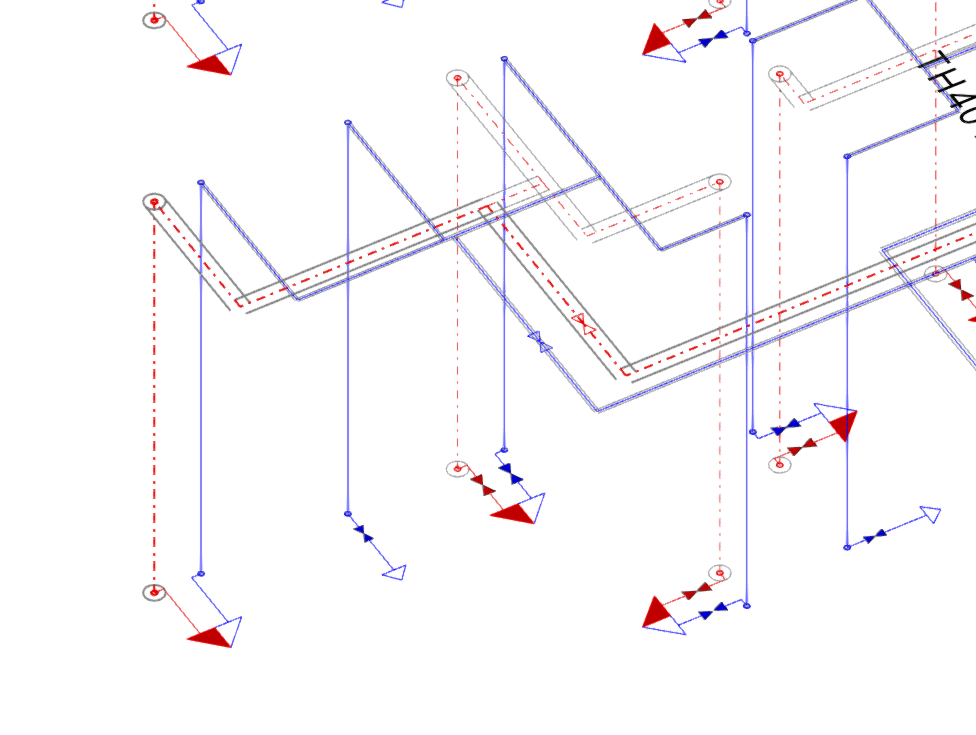

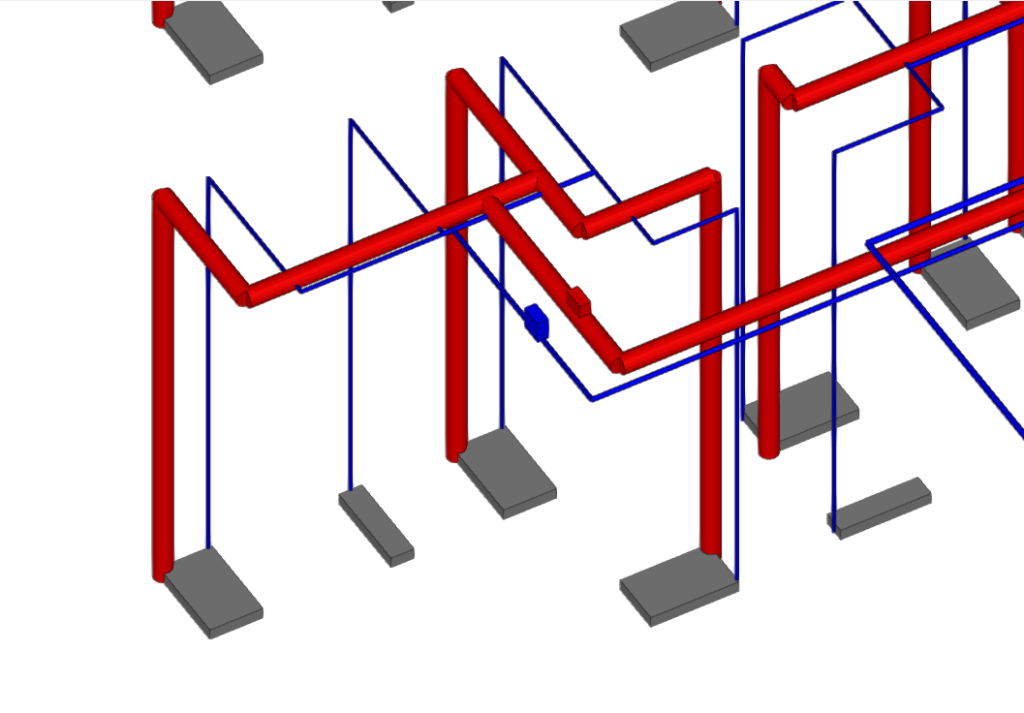

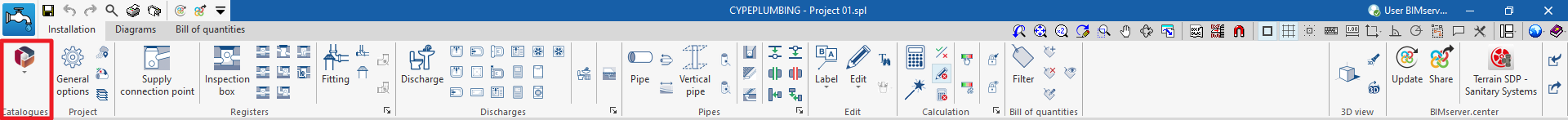

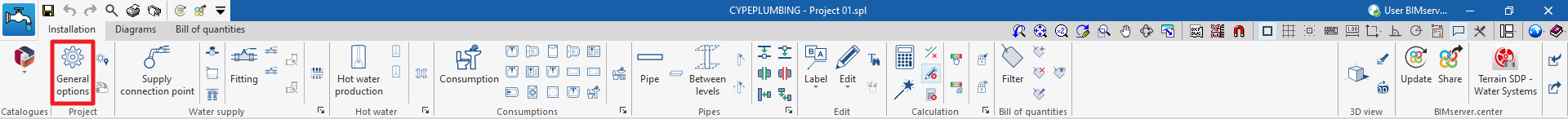

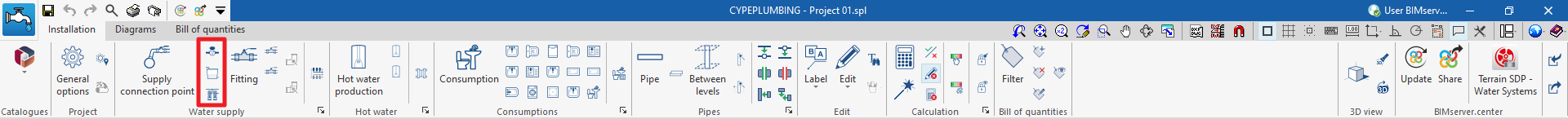

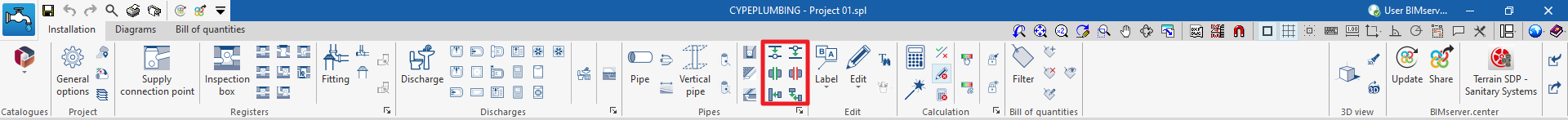

"Installation" tab

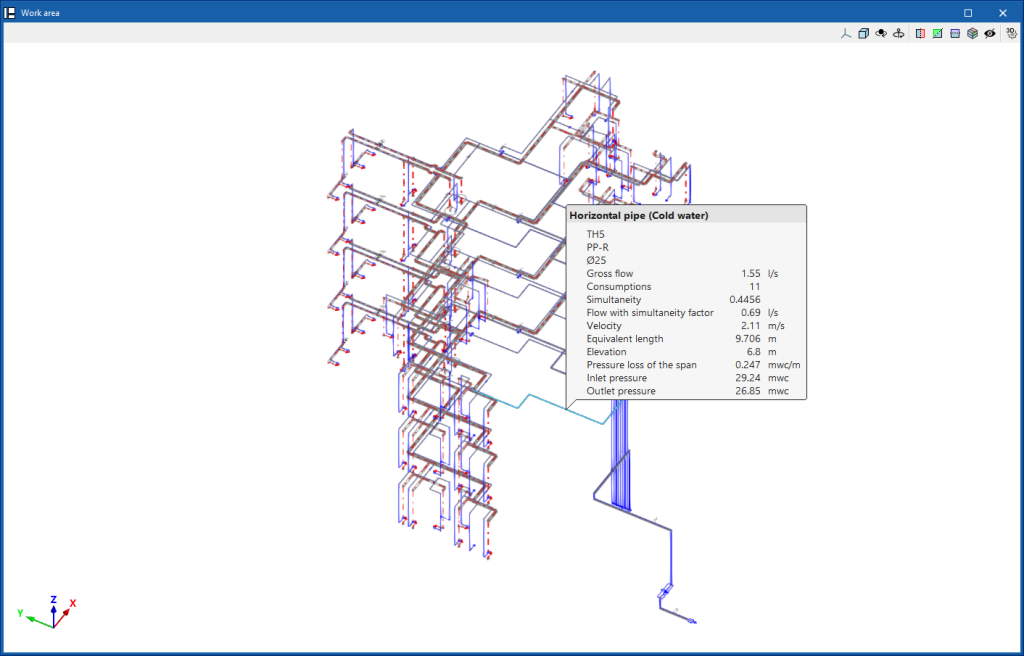

The "Installation" tab contains a work environment that is used to design the water supply system, both in a 3D view and in any type of 2D view (such as floor plans and elevations). This way, the elements in the system can be entered using the most appropriate view at any given time.

This tab displays the following:

- A top toolbar containing the tools for managing the catalogues and project options; entering and editing the elements of the water supply system (supply connection points, meters, tanks, pumping systems, fittings, collectors, hot water production equipment, heat exchangers and pipes); and analysing, checking and designing the system.

- The work area, on the right-hand side of the screen, where the aforementioned elements are entered, edited and displayed.

- On the left-hand side, several panels with tools for defining the views and levels of the project, managing the visibility of the elements read and configuring the layers and snapping options.

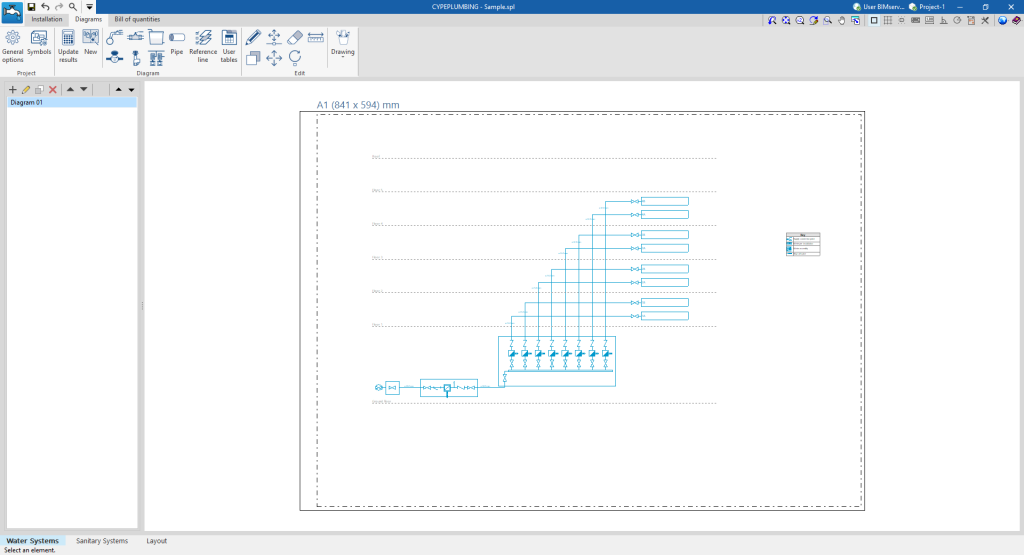

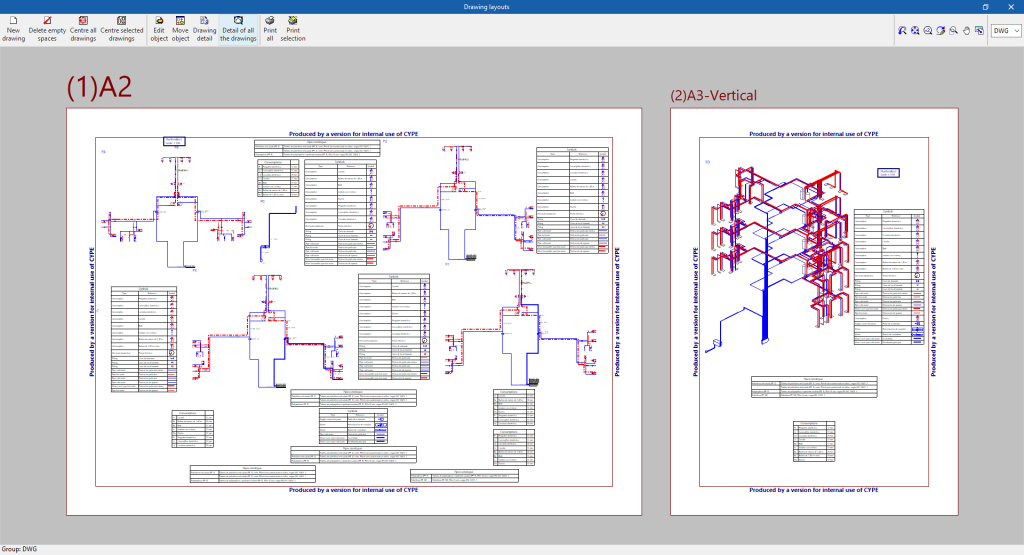

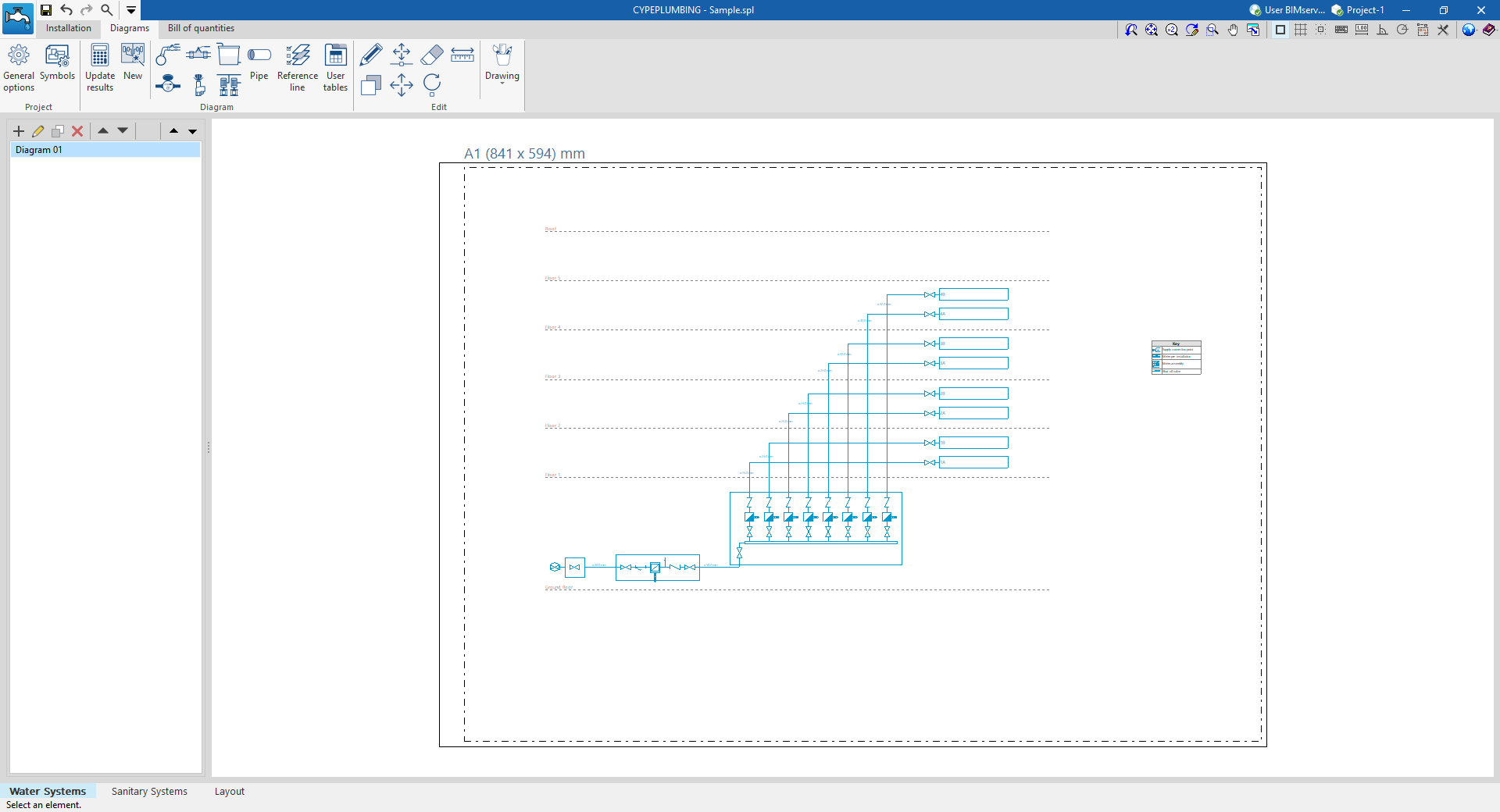

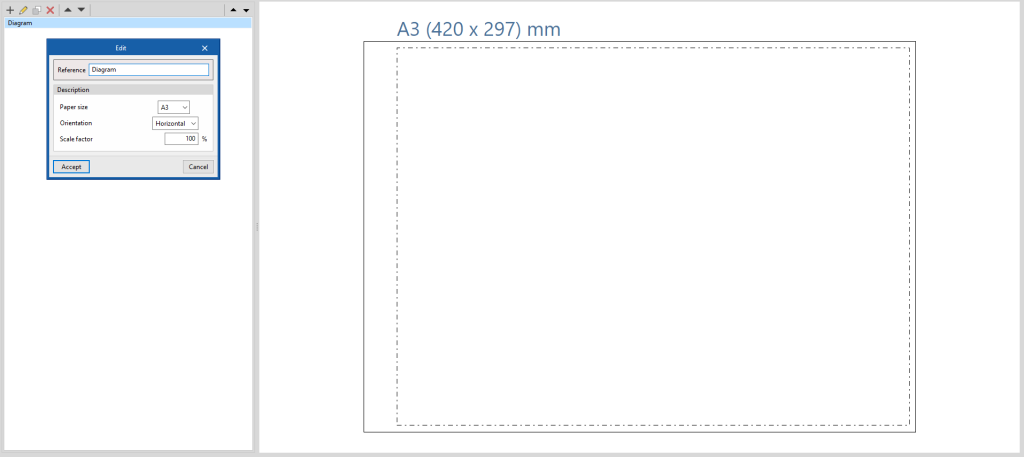

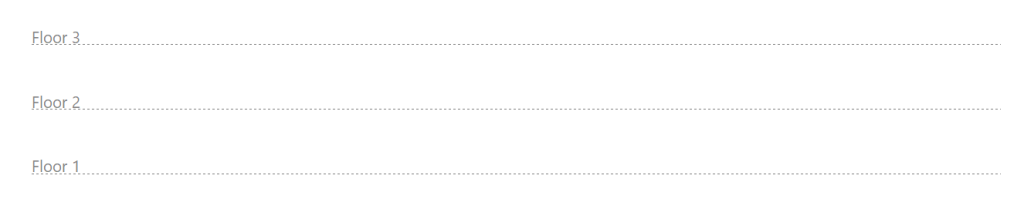

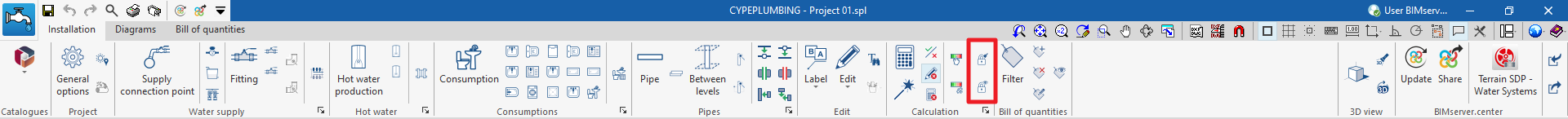

"Diagrams" tab

The "Diagrams" tab contains a work environment that is used to generate diagrams of the water supply system and to create them on sheets in the desired formats.

This tab displays the following:

- The top toolbar contains the tools for generating the water supply system diagrams; entering and editing the elements that make up the diagrams; and adjusting and configuring the general options and symbols.

- The workspace, on the right-hand side of the screen, where the system diagrams are entered, edited and displayed.

- On the left-hand side, a navigation panel between the different diagrams created, which are made up of sheets of editable format and scale.

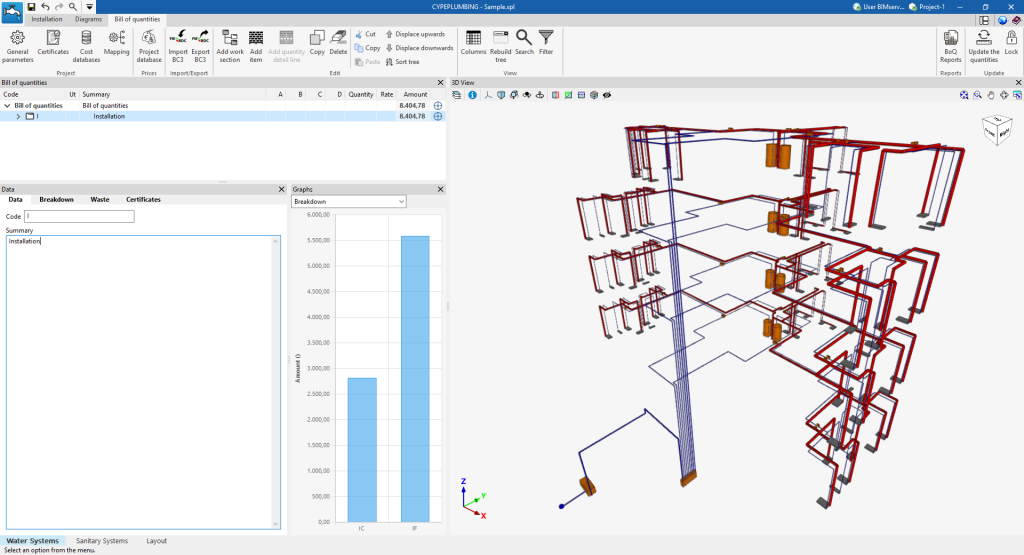

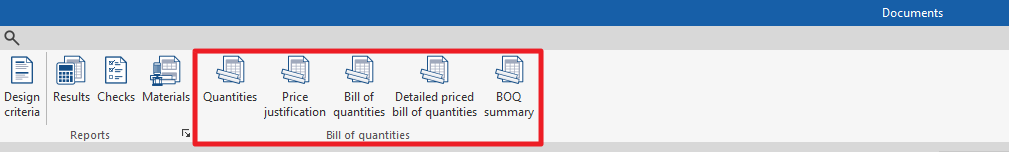

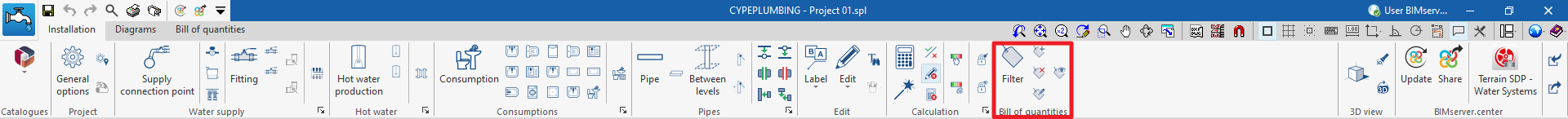

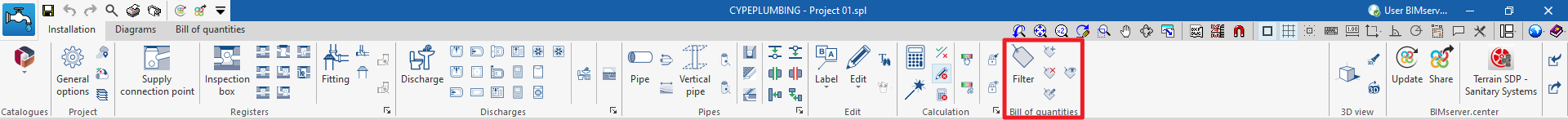

"Bill of quantities" tab

On the other hand, the "Bill of quantities" tab is used to manage the quantities and bill of quantities of the water supply systems, and displays the following:

- A top toolbar containing the tools for creating and editing the bill of quantities as well as those for managing and creating lists.

- A graphic window with its own toolbar, located on the right-hand side, where the different elements in the job can be viewed.

- A specific area for structuring the bill of quantities, on the left-hand side.

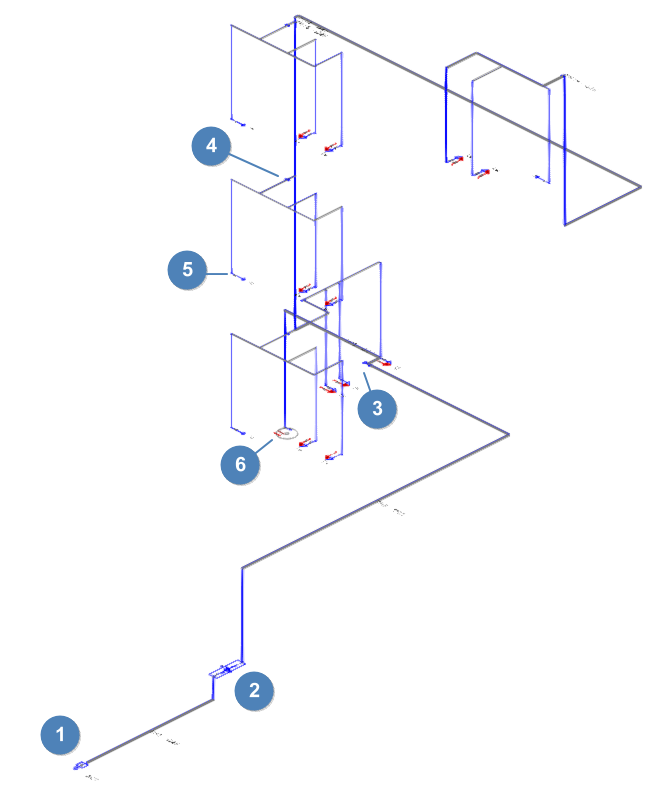

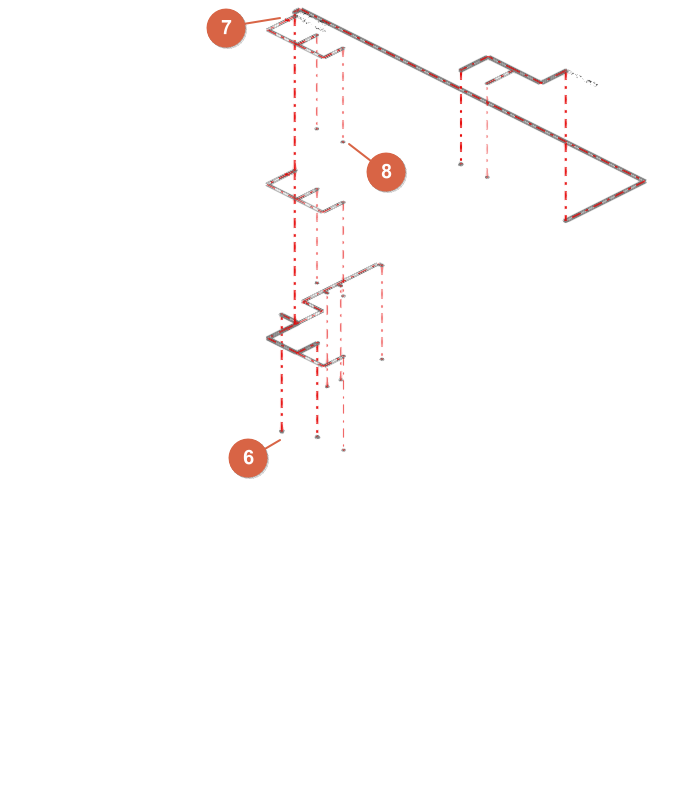

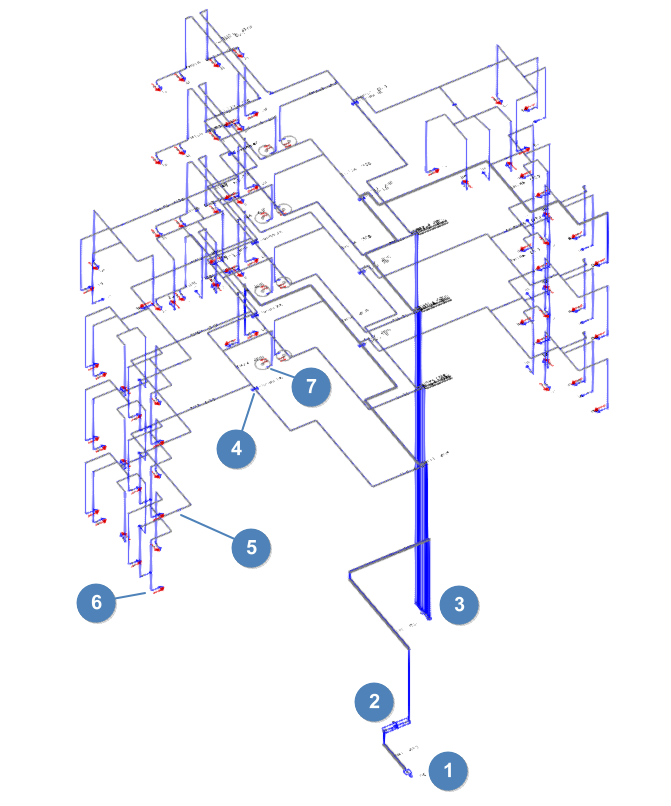

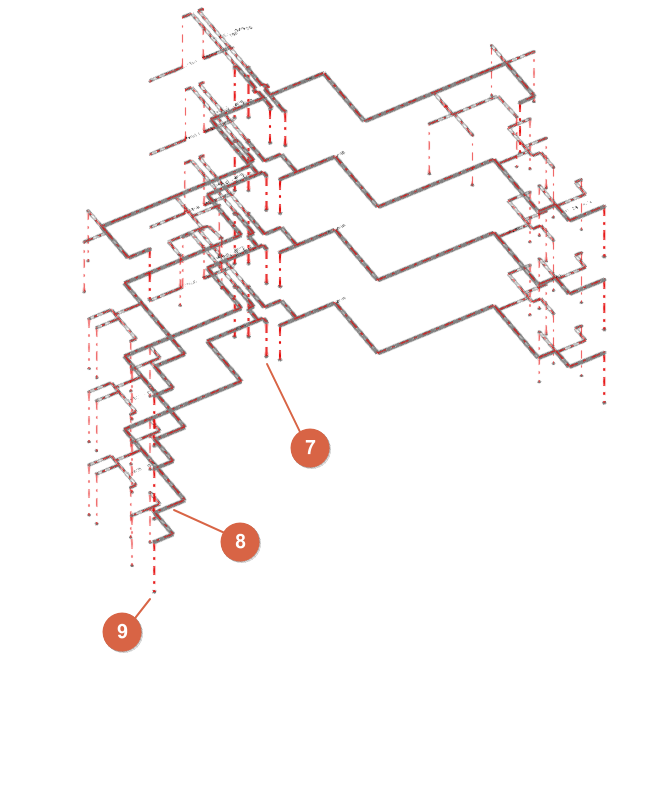

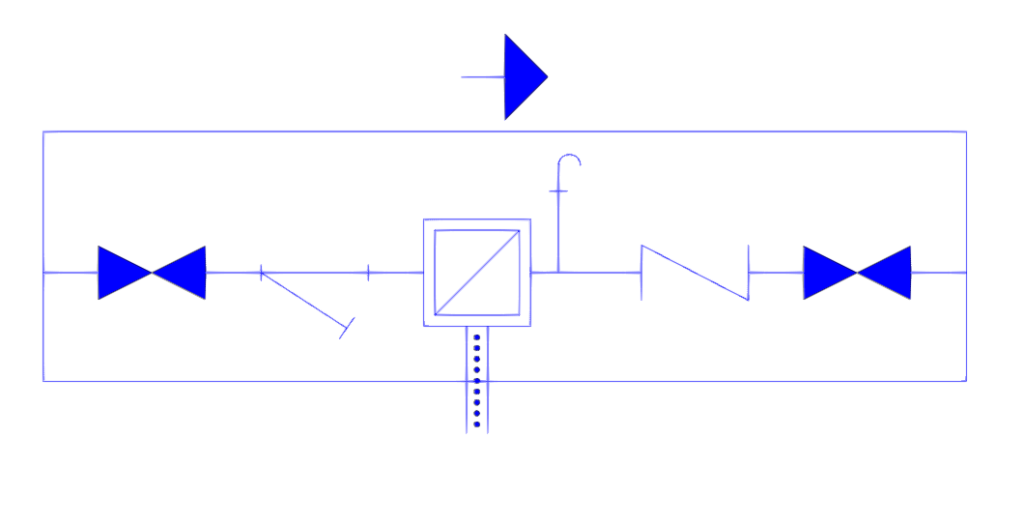

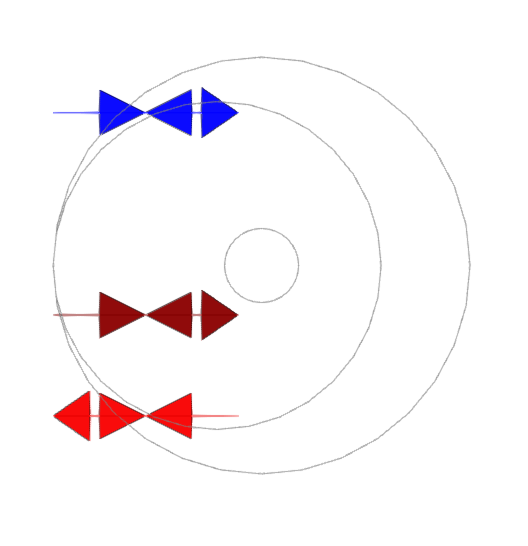

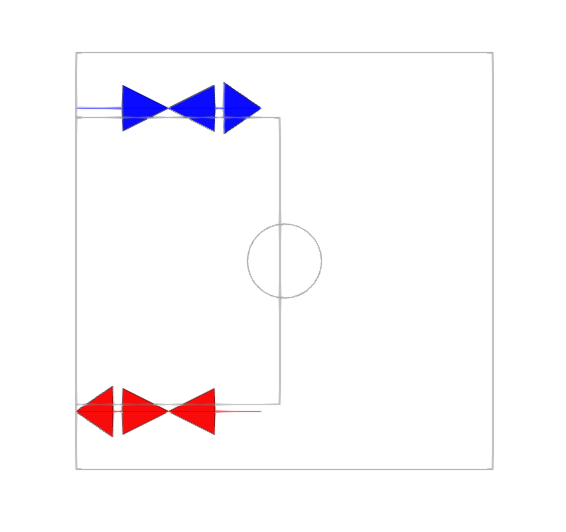

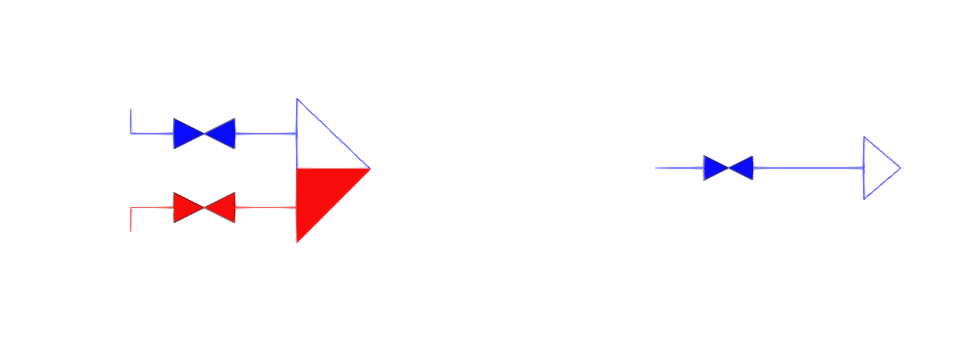

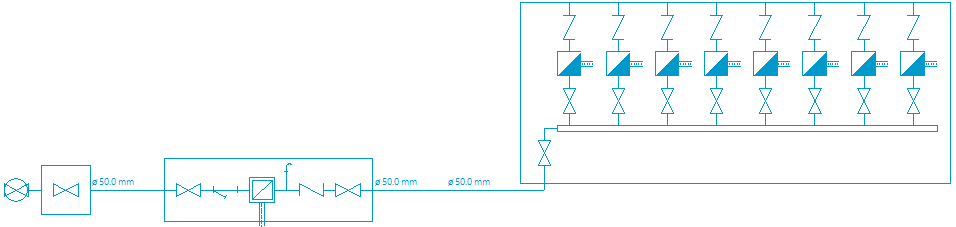

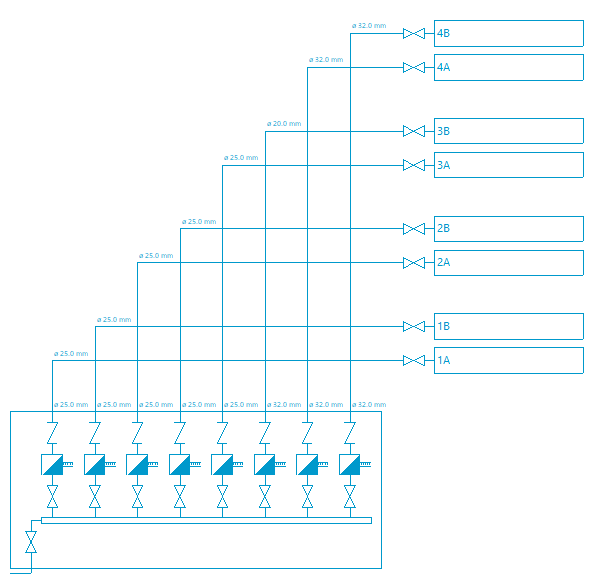

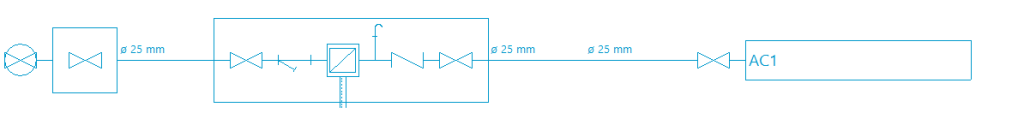

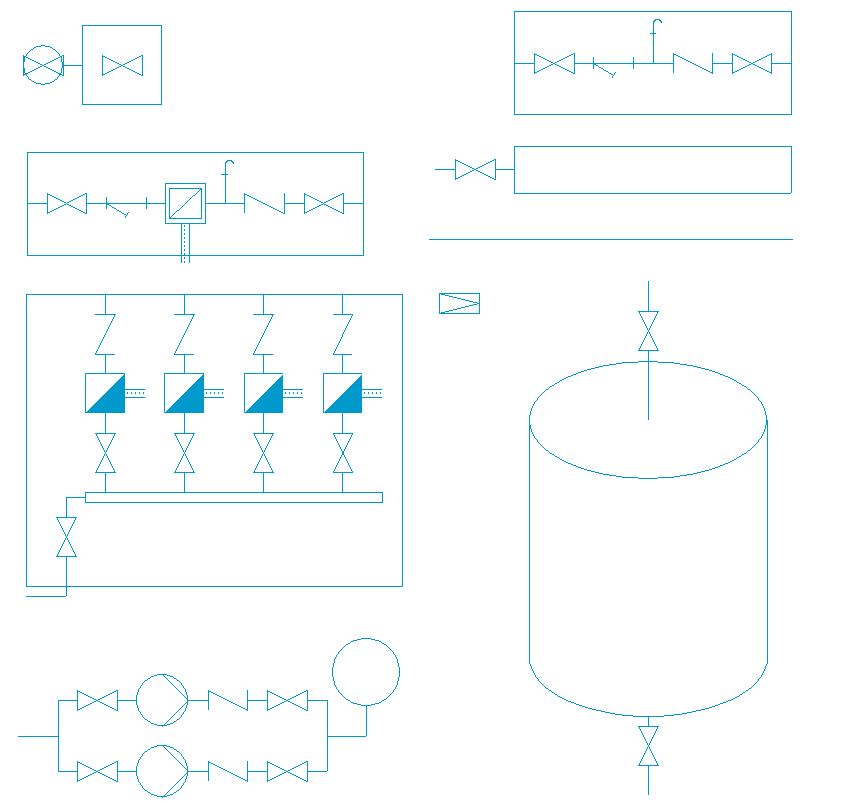

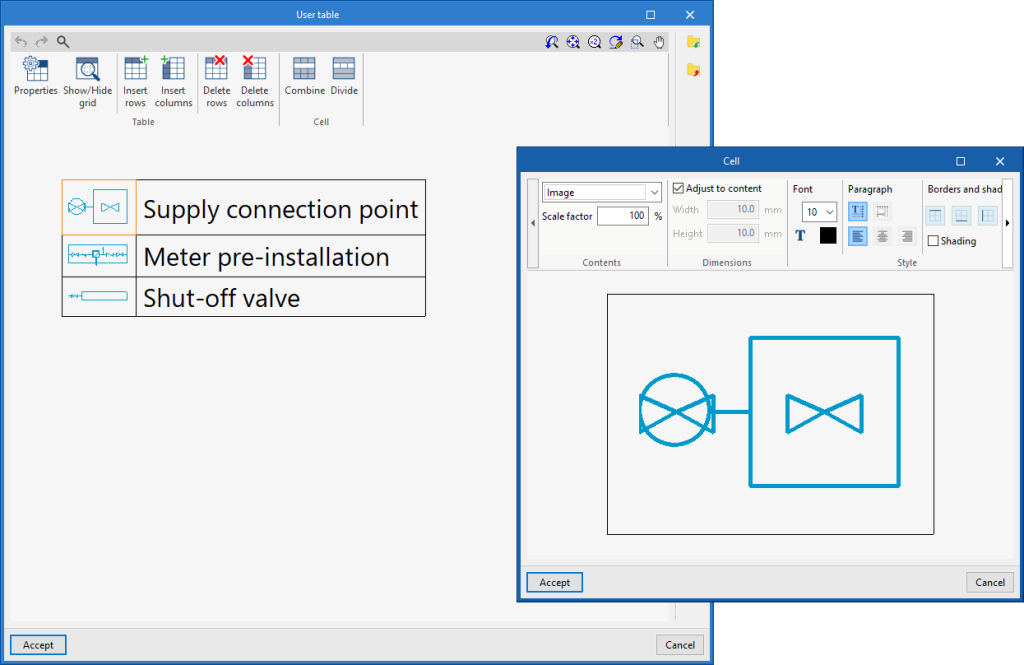

Examples of water supply system diagrams

Below are several diagrams of water supply systems that can be developed in the program, indicating the layout of the elements and the options that allow them to be entered into the model:

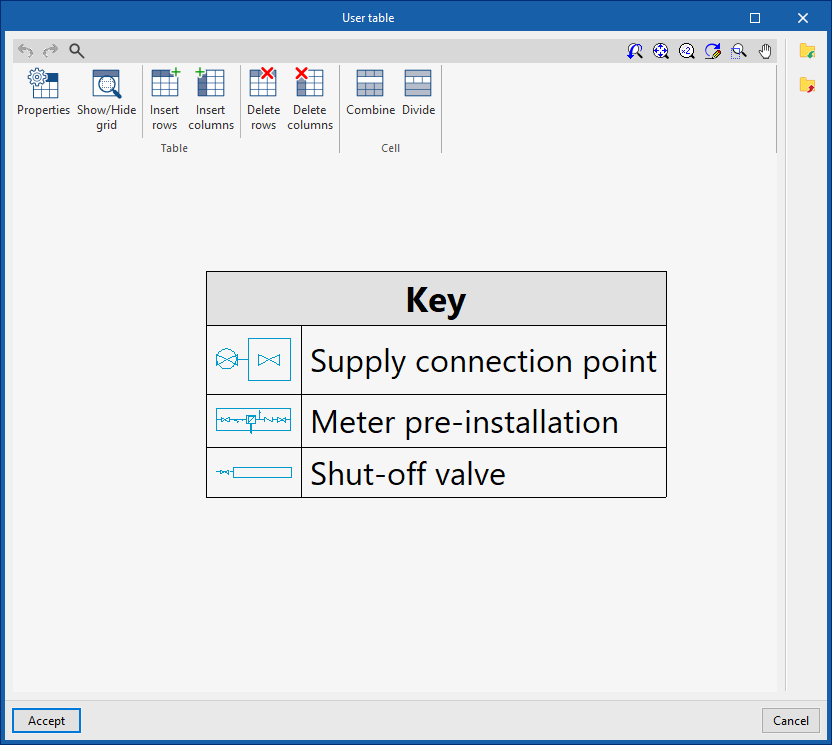

System with a single user

- Supply connection point ("Supply connection point" option).

- Meter pre-installation ("Meter" option).

- Shut-off valve ("Fitting" option).

- Cold water valve of the room with plumbing ("Fitting" option).

- Cold water consumption ("Consumption" option).

- Electric water heater ("Hot water production" option).

- Hot water valve of the room with plumbing ("Fitting" option).

- Hot water consumption ("Consumption" option).

System with more than one user with individual hot water production

- Supply connection point ("Supply connection point" option).

- Meter pre-installation ("Meter" option).

- Meter assembly ("Fitting" option).

- Main water shut-off valve ("Fitting" option).

- Cold water valve of the room with plumbing ("Fitting" option).

- Cold water consumption ("Consumption" option).

- Electric water heater ("Hot water production" option).

- Hot water valve of the room with plumbing ("Fitting" option).

- Hot water consumption ("Consumption" option).

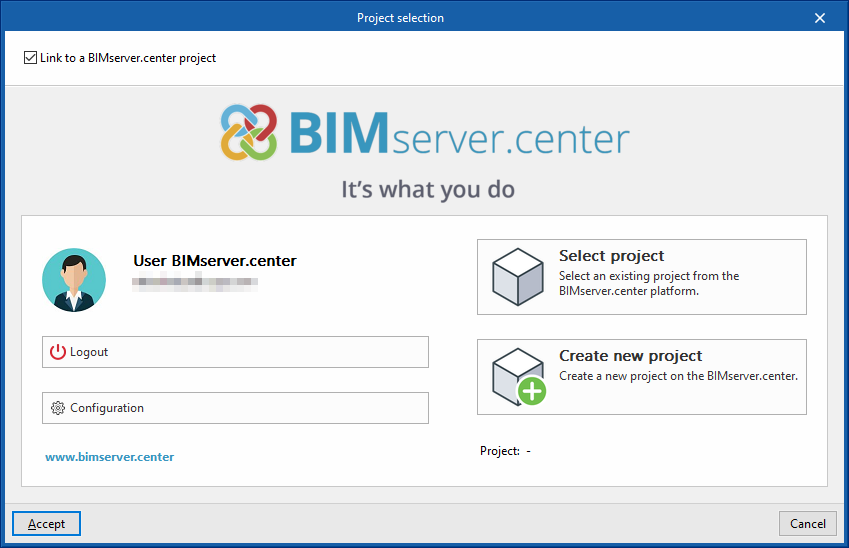

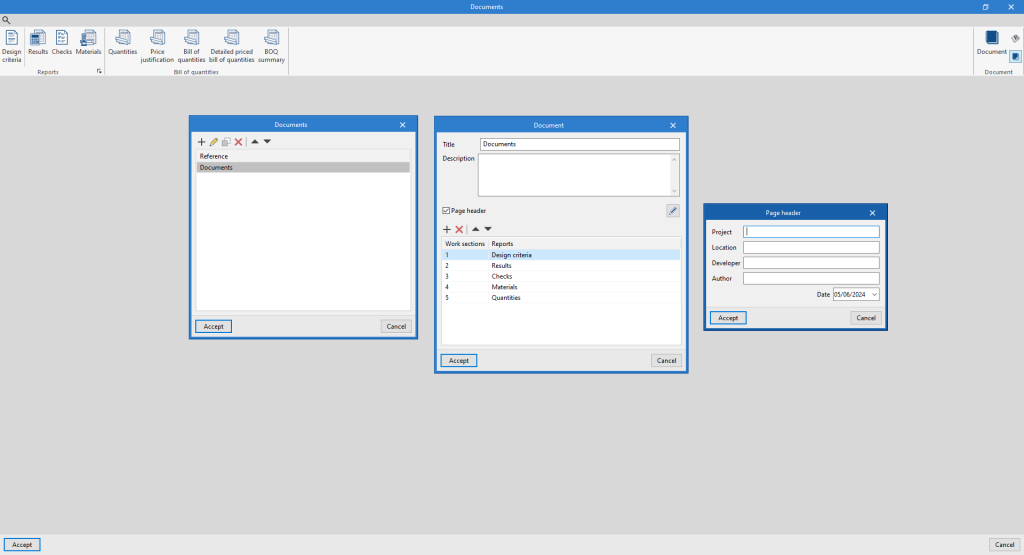

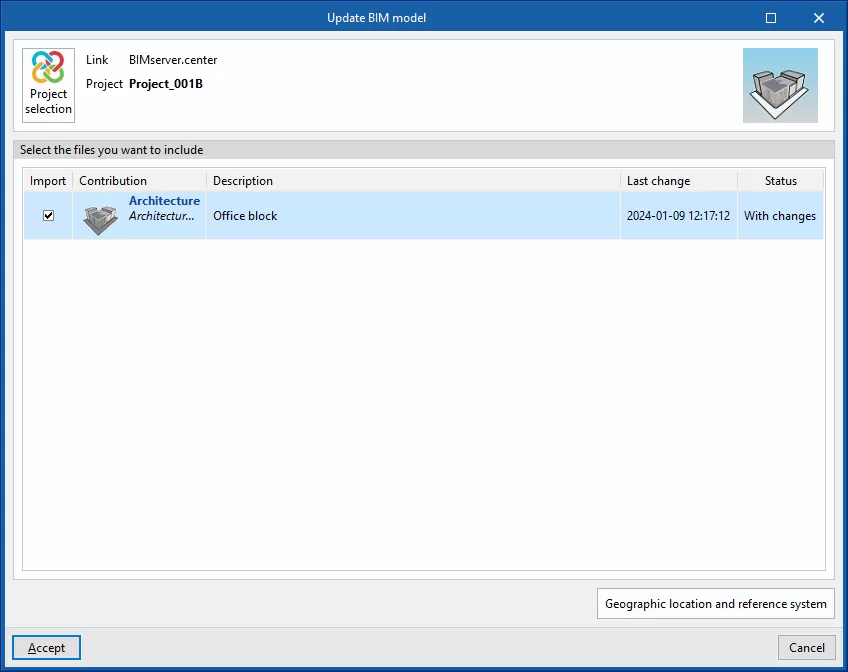

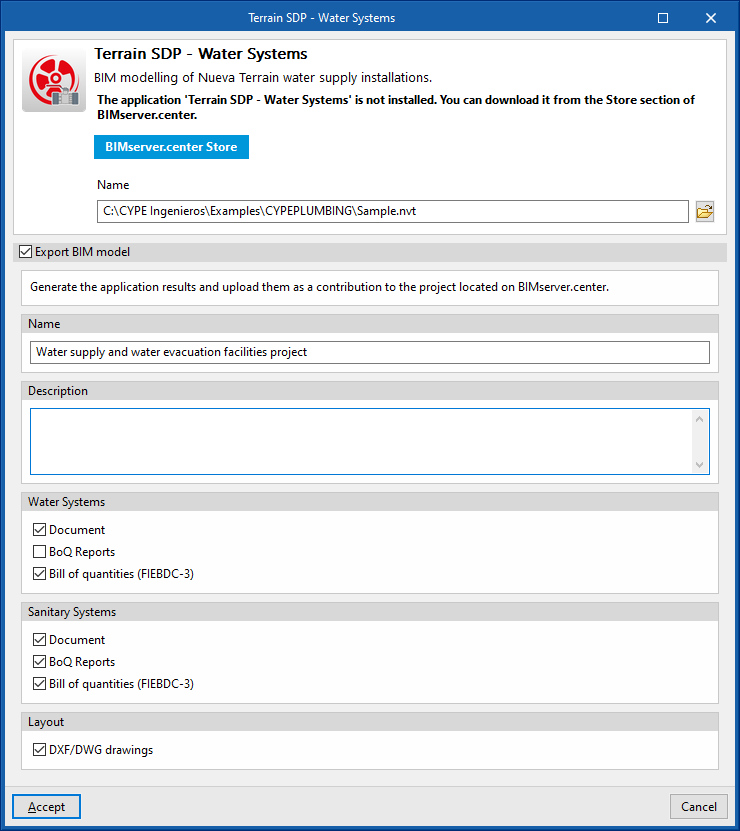

Creating a new job, linking to a project and importing data

When starting the application and clicking on "New", it offers users the chance to create a "New job", which can then be integrated into an existing project in BIMserver.center.

This is selected in the "Project selection" window. On the left-hand side, the user can log in with their BIMserver.center account.

Users can also "Create a new project". In this case, the created project will be visible from BIMserver.center from that moment on.

There is also the option of starting the project without being linked to the BIMserver.center platform. To do this, simply uncheck the box at the top left, "Link to a BIMserver.center project".

Once the new job has been created, the program interface is accessed, which includes a graphic window showing the model or models that have been imported.

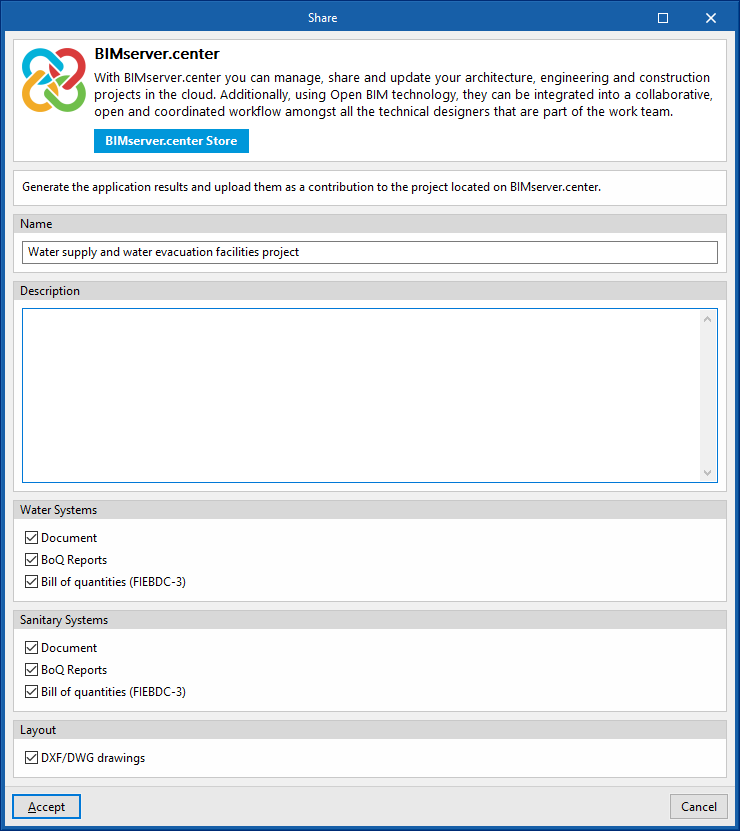

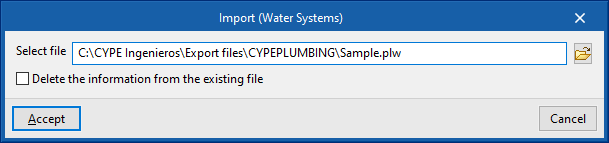

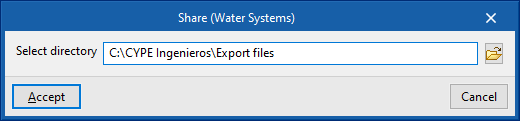

At any time during the project, files can be shared or imported via the "BIMserver.center" group at the top right-hand side of the screen.

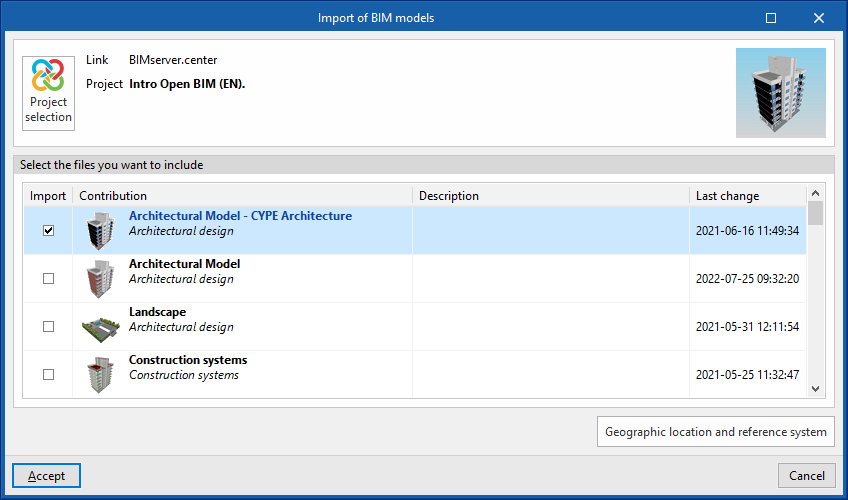

Importing BIM models

When creating a new job and selecting a project hosted on the BIMserver.center platform from "Select project", the "Import BIM models" window appears, which shows the files contained in that project in IFC format.

The application allows users to include one or more of the existing models in the project. To do this, the "Import" box is checked and accepted.

When accessing the interface, the graphic window will display the imported models. In addition, if they contain this information, it will create the views, levels and floor plans necessary for developing the system model.

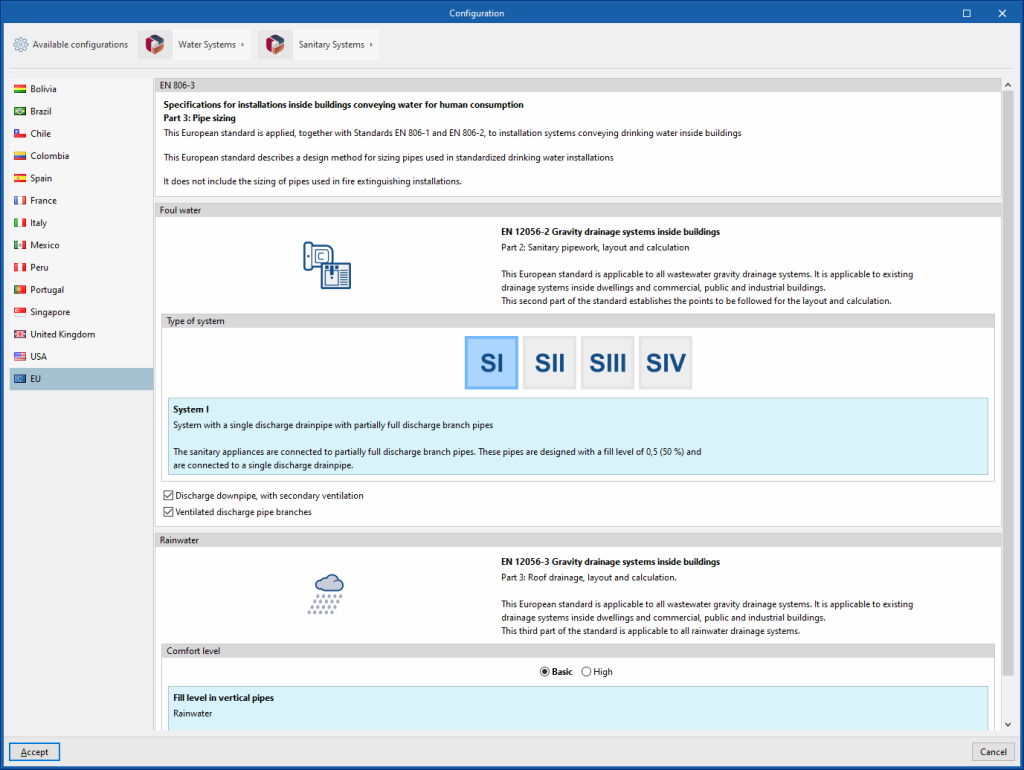

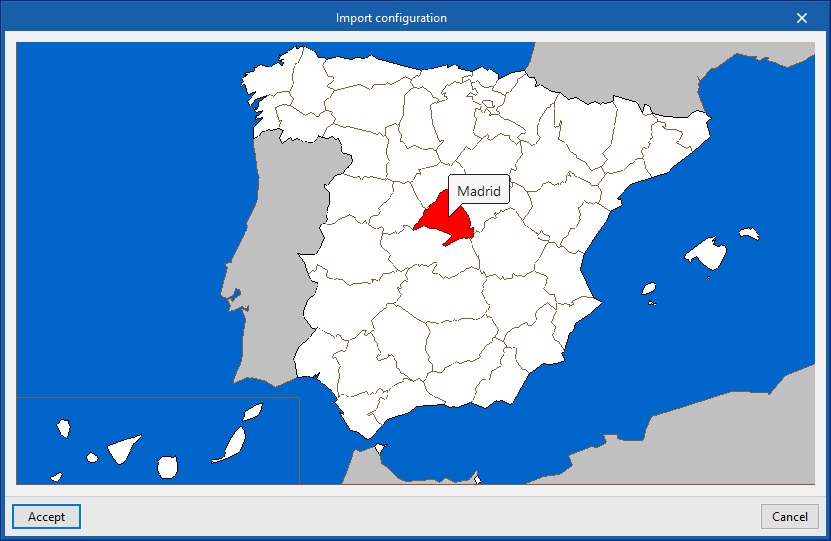

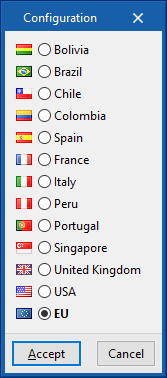

Importing configuration

Further on, the program opens the "Configuration" window, which allows the following:

- In the central part, users can select the configuration and the applicable codes from those available for different countries and regions. The selection is made for both the water supply system, developed in the "Water Systems" tab, and the water evacuation system, developed in the "Sanitary Systems" tab.

- The configuration provided by different manufacturers can also be imported via the "Available configurations" menu at the top left.

- Finally, the "Water Systems" and "Sanitary Systems" menus at the top allow the download and management of catalogues of different elements of the water supply and drainage systems.

If this window is closed or cancelled, the program will create the job without importing any settings.

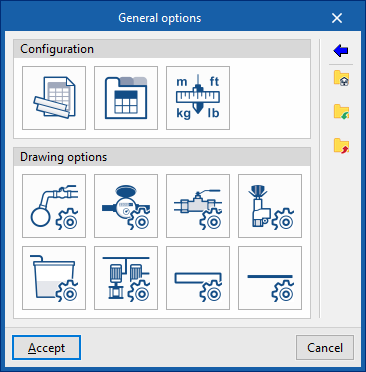

If users wish to subsequently load the configuration or customise it, or manage the job catalogues, they can use the "General options" and "Catalogues" tools in the top toolbar of the "Installation" tab, available in the "Water Systems" and "Sanitary Systems" tabs, respectively.

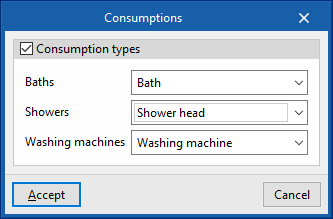

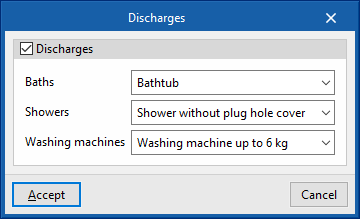

Generating consumptions and discharges from sanitary equipment

If the BIM model contains information on the sanitary appliances, when creating a new job, the program offers to associate them with the consumption and discharge types defined in the configuration of the building. This automatically generates the consumption and discharge points and arranges them in the model space.

Managing manufacturers' catalogues

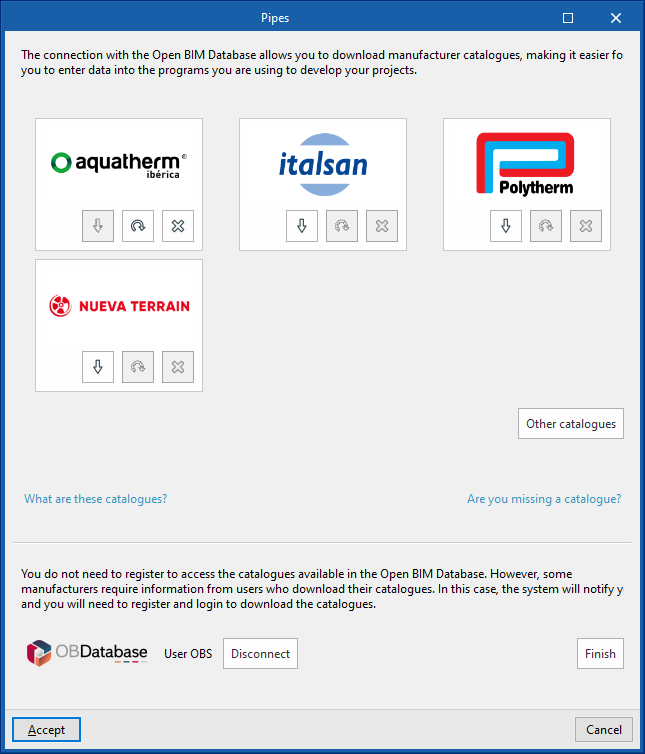

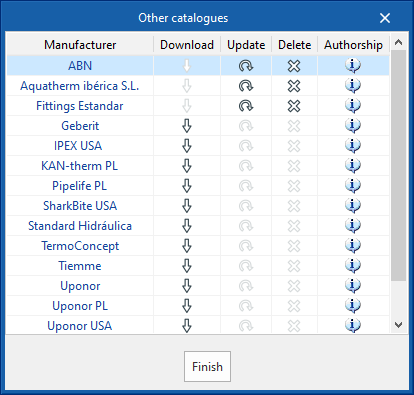

In the "Catalogues" group of the main toolbar of the "Installation" tab, either in the "Water Systems" tab or in the "Sanitary Systems" tab, there are tools for managing manufacturers' catalogues in the water supply or water evacuation system, respectively:

Catalogues

Downloads manufacturers' catalogues using the Open BIM Database connection, making it easier to enter data into the program for the project development.

Clicking on this option opens a menu where the desired element can be selected. When doing this, a window opens with the available manufacturer's catalogues for that element.

Download catalogues

The following options are shown for each manufacturer:

- Download

Download the manufacturer's catalogue. The products in the catalogue will be available in the project. - Update

Updates the selected manufacturer's catalogue to the latest version, deleting the version downloaded in the project. - Delete

Deletes the selected manufacturer's catalogue. The products in the catalogue will no longer be available in the project.

Connection to Open BIM Database

At the bottom of this dialogue box, the program allows users to log in with their Open BIM Database account and password.

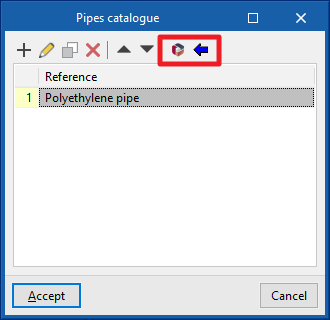

Importing catalogue data

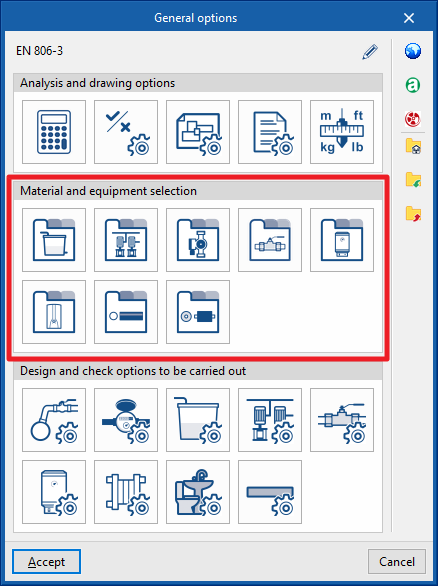

The manufacturers' catalogues downloaded in the project are available when creating materials and equipment for the elements in the system from the different options in the “Material and equipment selection” section of the “General options”, using the “Available manufacturers” button located at the top right of each table.

From here, catalogues can also be downloaded, using the "Catalogues" button next to the one above.

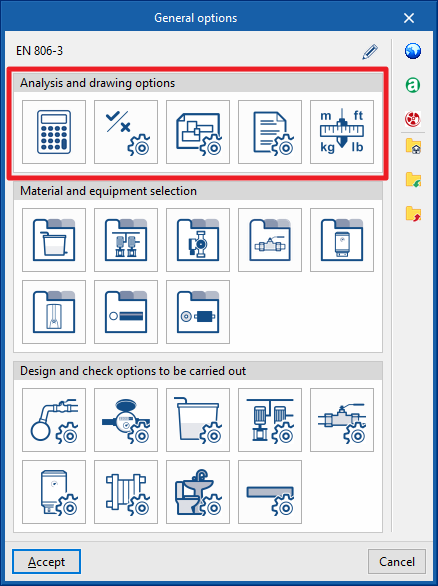

Setting the analysis and drawing options for the water supply system

In the "Installation" tab of the "Water Systems" tab, in the "General Options" of the "Project" group in the main toolbar, the "Analysis and drawing options" of the water supply system can be configured:

- Calculation options

- General checks

- Representation options

- Report configuration

- Units

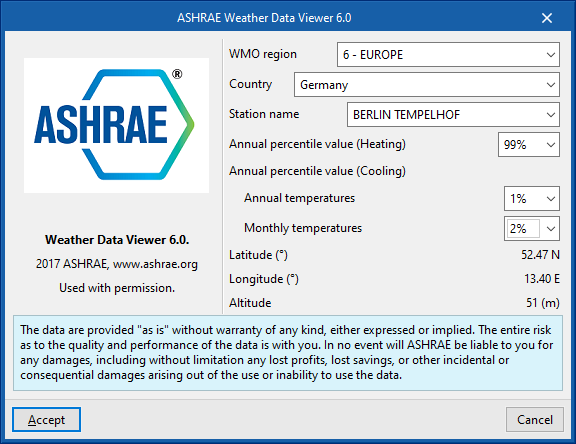

By using the "Import configuration" option, available on the right-hand side of the "General options" panel, this data can be automatically generated for different national and international standards. Similarly, data from different manufacturers can be imported by clicking on the options with their logo.

The other options in the right-hand column are for importing and exporting the complete configuration of the "General options" panel to files on disk, as well as selecting a file with initial values for creating a new job.

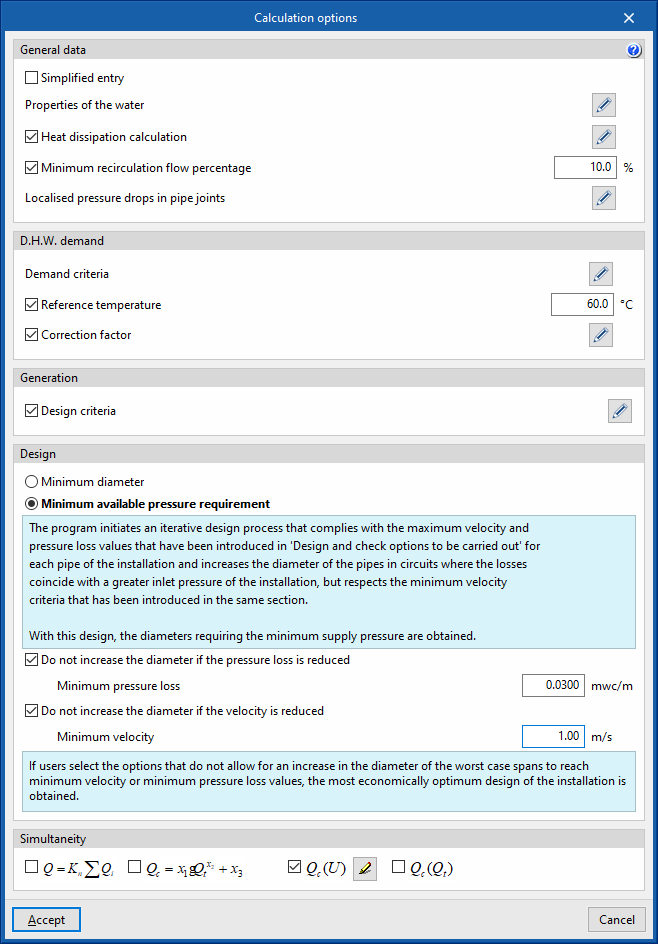

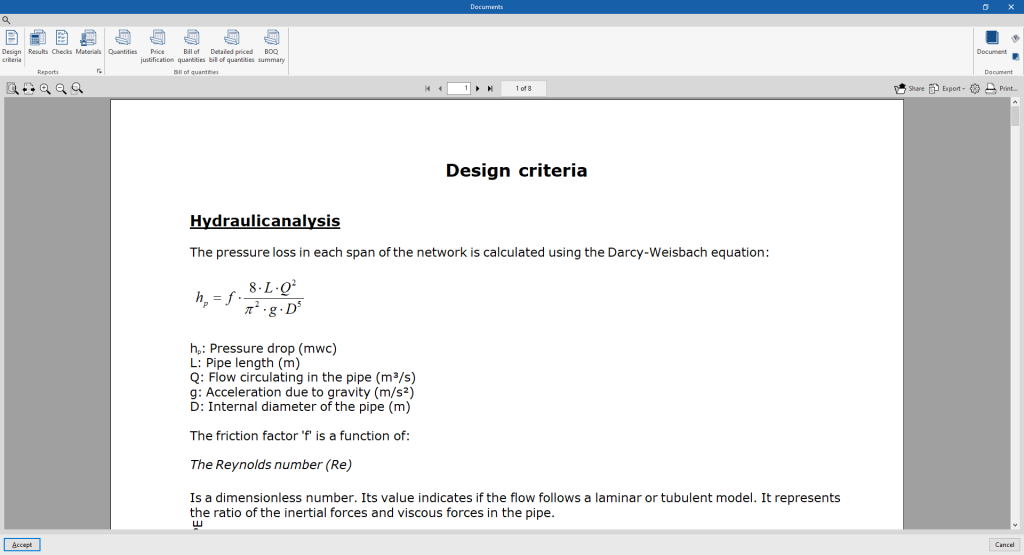

Calculation options

Defines the general data and criteria for the design of the water supply system.

- General data

The formula used in the hydraulic analysis of the system can be consulted using the help button on the right-hand side of this section. The Darcy-Weisbach formula is used to calculate the pressure losses in each section of the network. The expressions that determine the analysis of the hot water return networks are also shown.- Simplified entry (optional)

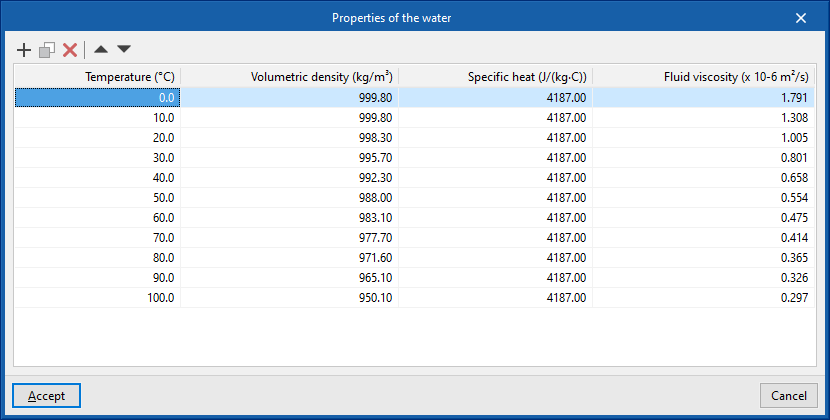

If this option is activated, the panels for entering and editing the elements in the system have a simplified appearance and don't need to be defined by the user. - Properties of the water

This allows the density, specific heat and viscosity of water to be defined for each temperature value. - Heat dissipation calculation (optional)

Activates the heat dissipation calculation. The ambient temperature value must be entered. - Minimum recirculation flow percentage (optional)

Defines a minimum recirculation flow percentage in the hot water return circuits. - Localised pressure drops in pipe joints

Selects the type of local pressure drop to be assigned at the joints of the different kinds of pipes when using the tools for automatically generating "Local pressure drops at pipe joints" available in the "Water supply" group of the main toolbar. The library of pressure loss types can be configured from "Fittings", in the "Design and check options to be carried out" section of the "General options".- Cold water (45° elbow, 90° elbow, Tee, Reducer)

- Hot water (45° elbow, 90° elbow, Tee, Reducer)

- Hot water return (45° elbow, 90° elbow, Tee, Reducer)

- Auxiliary supply (45° elbow, 90° elbow, Tee, Reducer)

- Auxiliary return (45° elbow, 90° elbow, Tee, Reducer)

- Simplified entry (optional)

- D.H.W. demand

- Demand criteria

Defines the available DHW demand criteria, indicating the reference, description and daily demand, per unit (in volume units). This criteria can then be selected to enter the necessary information in the "Consumption" section of the "DHW production" equipment. - Reference temperature (optional)

Defines the reference temperature of the DHW demand. - Correction factor

Defines a correction factor for the DHW demand according to the number of consumers.

- Demand criteria

- Generation

- Design criteria (optional)

Selects the type of pipe that the program assigns to each span of the system during the design, if the "Pipe reference" section is kept unlocked in each pipe entered in the model. The kinds of pipes can be created in "Pipes", in the "Design and check options to be carried out" section of the "General options".- Cold water (Supply connection points, Meter pre-installation, Meter assembly, Shut-off valve, Valve of the room with plumbing, Consumption, Others)

- Hot water (Hot water production, Meter pre-installation, Meter assembly, Shut-off valve, Valve of the room with plumbing, Consumption, Others)

- Design criteria (optional)

- Design

- Minimum diameter

If this option is chosen, the system design is carried out with the maximum values of velocity and pressure loss entered for each pipe from "Pipes", in the "Design and check options to be carried out" section of the "General options". With this design, the minimum possible diameters are obtained, if the supply pressure is sufficient. - Minimum available pressure requirement

If this option is chosen, the program starts an iterative design process which, as well as complying with the maximum values of velocity and head loss introduced for each pipe (in "Piping", in the "Design and check options to be carried out" section of the "General options") increases the diameter of the pipes in the circuits where the losses condition a higher inlet pressure in the system, respecting the minimum velocity criteria entered in the same section. This design obtains the diameters that require the minimum possible supply pressure. Furthermore, if the following options are selected, which do not allow the diameter of the most unfavourable sections to be increased when reaching a minimum speed or a minimum pressure loss, a sizing of the system that is closer to the optimum economic design is obtained:- Do not increase the diameter if the pressure loss is reduced (optional)

- Minimum pressure loss

- Do not increase the diameter if the velocity is reduced (optional)

- Minimum velocity

- Do not increase the diameter if the pressure loss is reduced (optional)

- Minimum diameter

- Simultaneity

Selects and defines the simultaneity analysis methods available in the project. It is then possible to choose one of these methods for each pipe defined in "Pipes", in the "Design and check options to be carried out" section of the "General options".- Q = Kn Σ Qi

Defines the simultaneous flow rate as a function of the sum of the instantaneous flow rates (Qi) and the coefficient (Kn). This coefficient depends on the number n of consumptions and its calculation expression takes different forms, which can be selected for each pipe defined in "Pipes", in the "Design and check options to be carried out" section of the "General options". - Qc = x1 × Qtx2 + x3

Defines the simultaneous or calculation flow rate as a function of the gross flow rate (Qt) and the x1, x2 and x3 parameters, which can be defined by flow rate ranges. This method is proposed in some documents such as the UNE 149201:2017 standard. - Qc (U)

Defines the simultaneous or calculation flow rate (Qc) as a function of the number of consumption units (U). - Qc (Qt)

Defines the simultaneous or calculation flow rate (Qc) as a function of the gross flow rate (Qt).

- Q = Kn Σ Qi

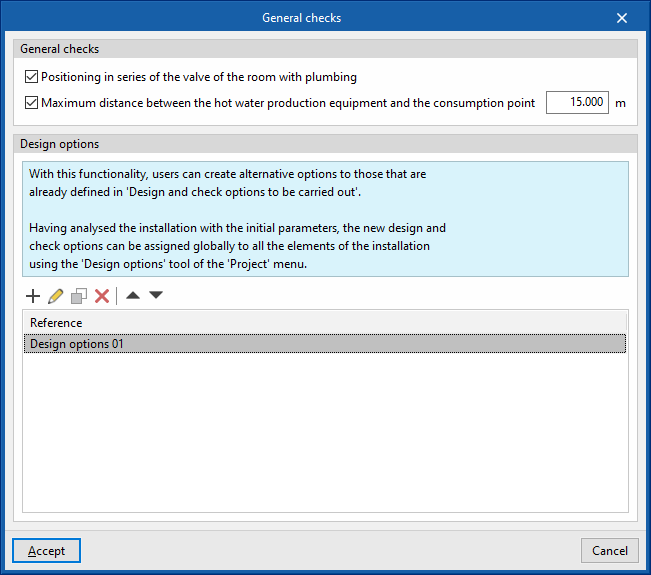

General checks

Defines the general checks of the water supply system.

- General checks

- Positioning in series of the valve of the room with plumbing (optional)

- Maximum distance between the hot water production equipment and the consumption point (optional)

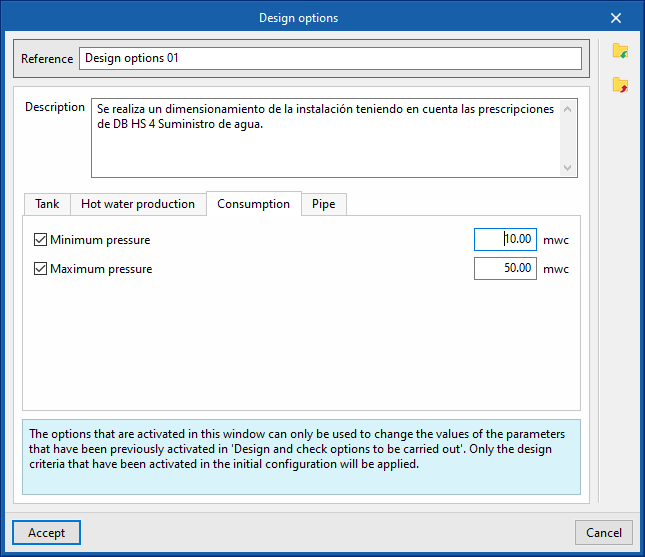

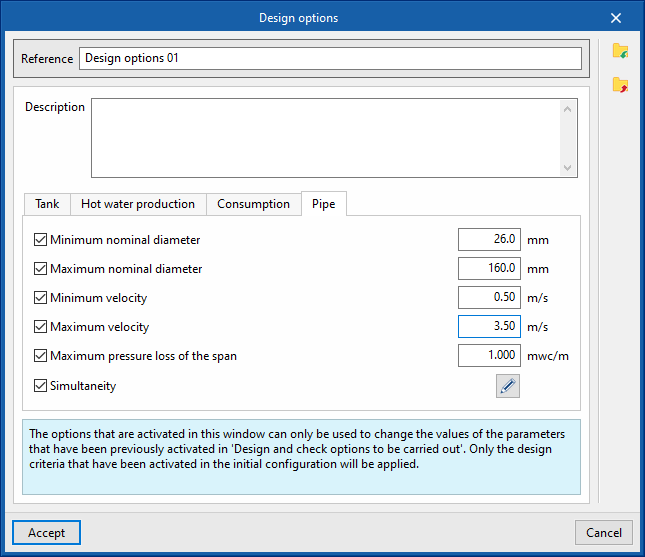

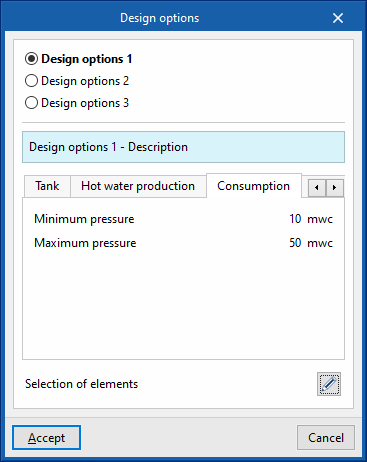

- Design options

With this feature, users can configure alternative design options globally for all the elements in the system. The parameters activated and entered in this window are only used to change the values of the parameters that are previously activated in each type of element defined in the "General options", from where the "Design and check options to be carried out" are accessed. Furthermore, once defined, these options will not be applied to the design of the system until the user assigns them using the "Design options" option in the "Project" group of the top tool menu in the general interface.- Reference

- Description

- "Deposit" tab

- Minimum pressure (optional)

- Maximum pressure (optional)

- “Hot water production” tab

- Minimum pressure (optional)

- Maximum pressure (optional)

- “Consumption” tab

- Minimum pressure (optional)

- Maximum pressure (optional)

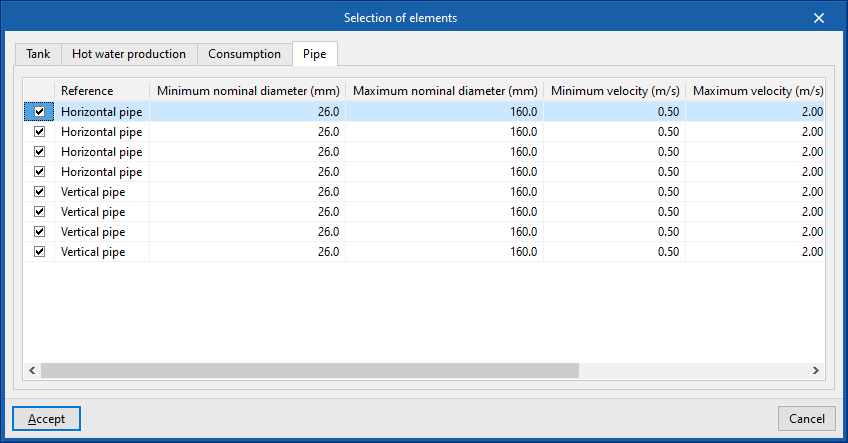

- “Pipe” tab

- Minimum nominal diameter (optional)

- Maximum nominal diameter (optional)

- Minimum velocity (optional)

- Maximum velocity (optional)

- Maximum pressure loss of the span (optional)

- Simultaneity (optional)

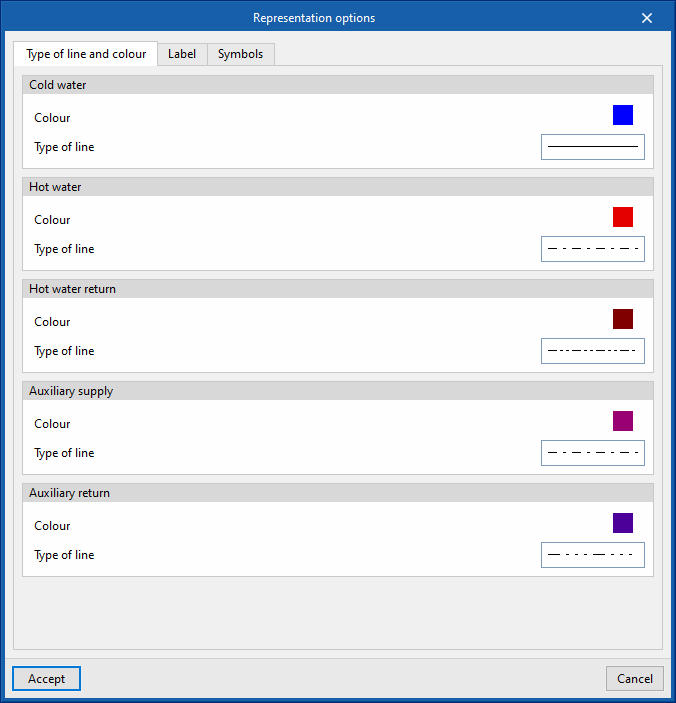

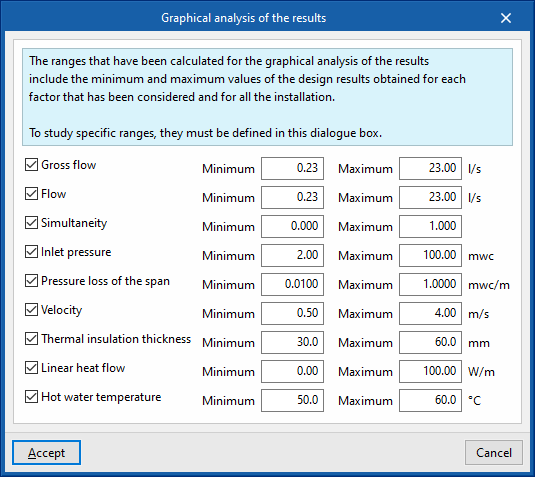

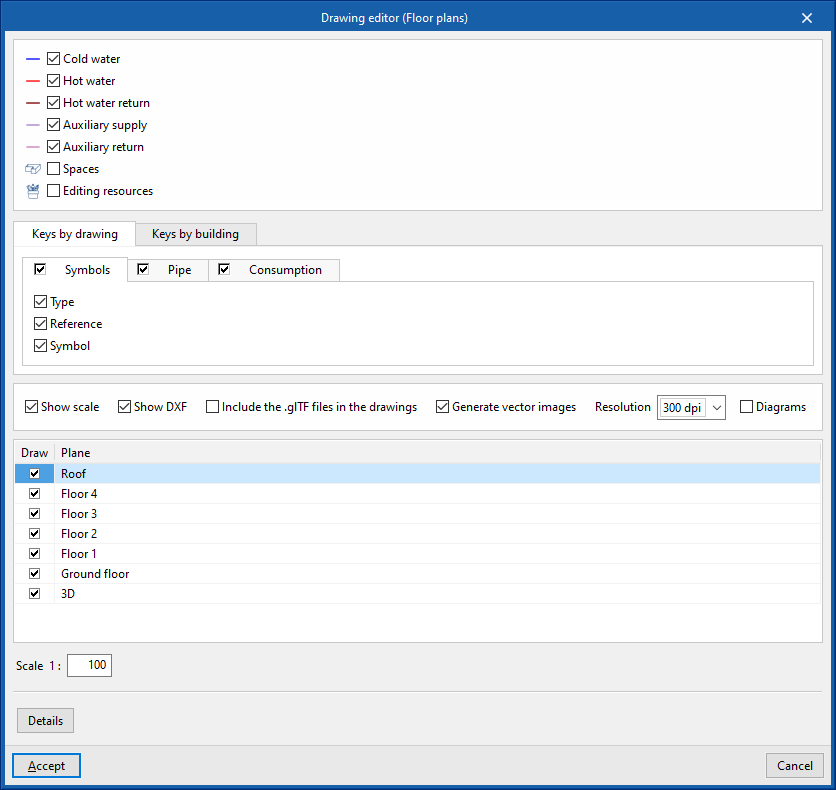

Representation options

Configures the graphical representation of the elements in the water supply system.

- “Type of line and colour” tab

Modifies the type of line and the colour used in the graphical representation of the different types of pipes.- Cold water (Colour, Type of line)

- Hot water (Colour, Type of line)

- Hot water return (Colour, Type of line)

- Auxiliary supply (Colour, Type of line)

- Auxiliary return (Colour, Type of line)

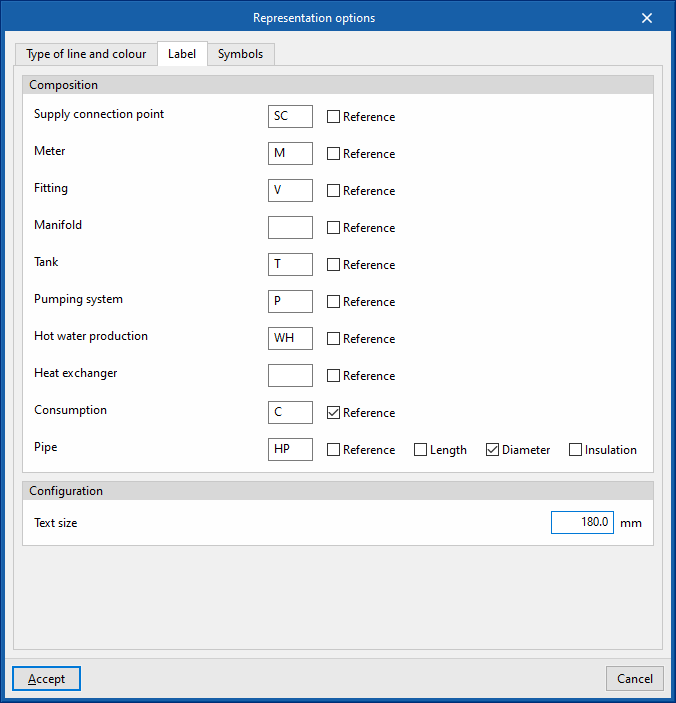

- “Label” tab

Adjusts the information displayed in the labels of the different elements in the water supply system and their text size.- Composition (Supply connection point, Meter, Fitting, Manifold, Tank, Pumping system, Hot water production, Heat exchanger, Consumption, Pipe)

- Configuration

- Text size

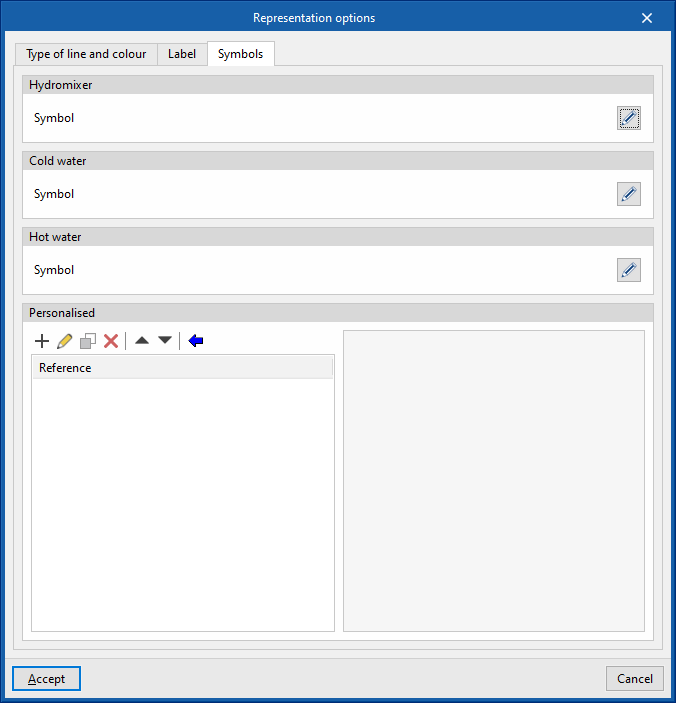

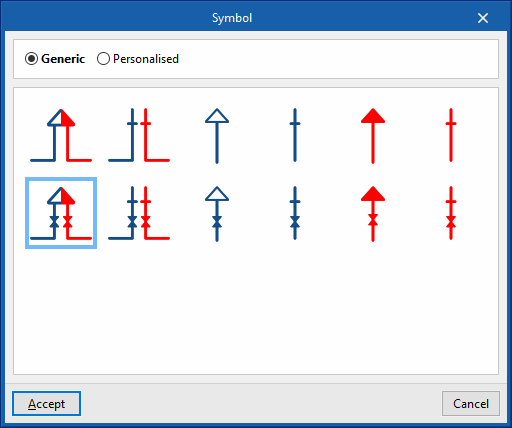

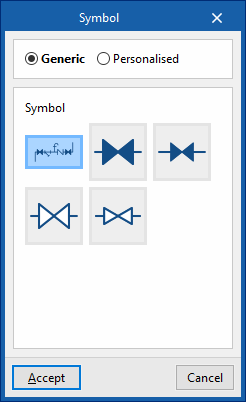

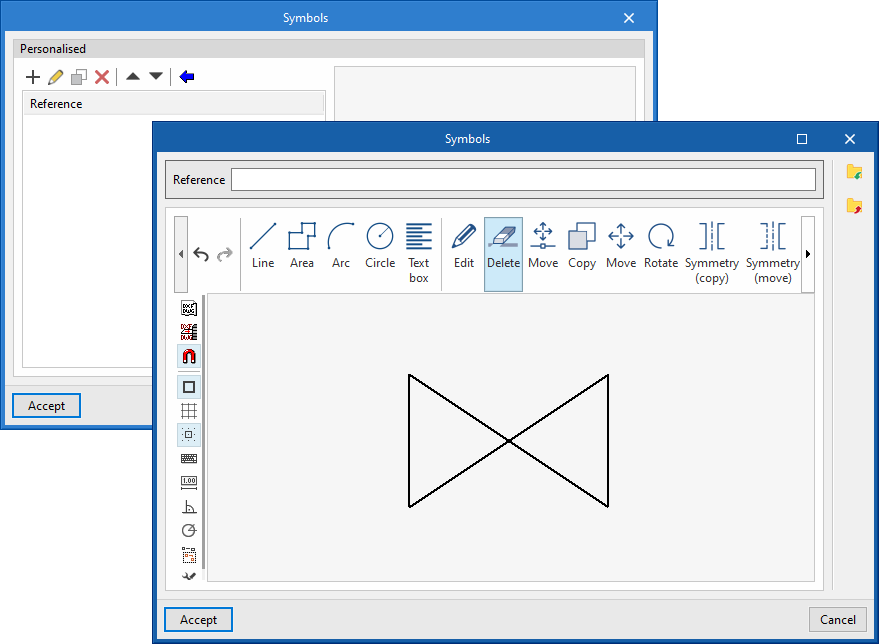

- “Symbols” tab

- Hydromixer (Symbol), Cold water (Symbol), Hot water (Symbol)

Selects the symbol used in the graphical representation of the water supply system consumption from the generic symbols available or the previously created customised symbols. - Personalised

Creates customised symbols using a drawing editor or imports symbols contained in DXF, DWG or DWF files saved on disk.

- Hydromixer (Symbol), Cold water (Symbol), Hot water (Symbol)

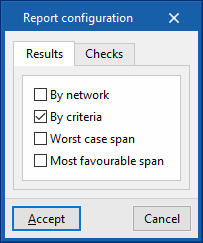

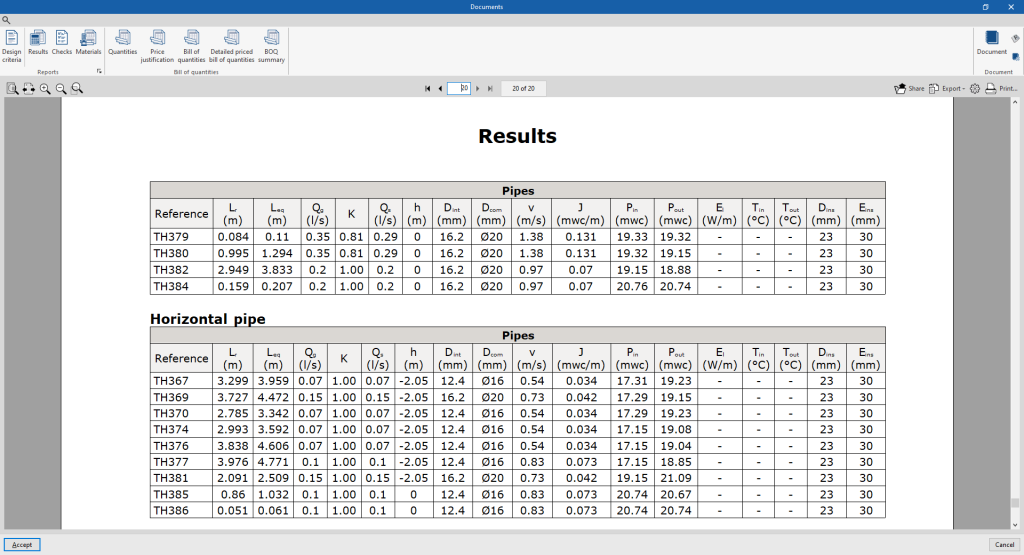

Report configuration

Configures the information that appears in the water supply system reports.

- Results

Configures the information that appears in the results report.- By network (optional)

- By criteria (optional)

- Worst case span (optional)

- Most favourable span (optional)

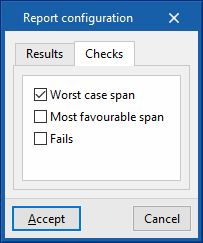

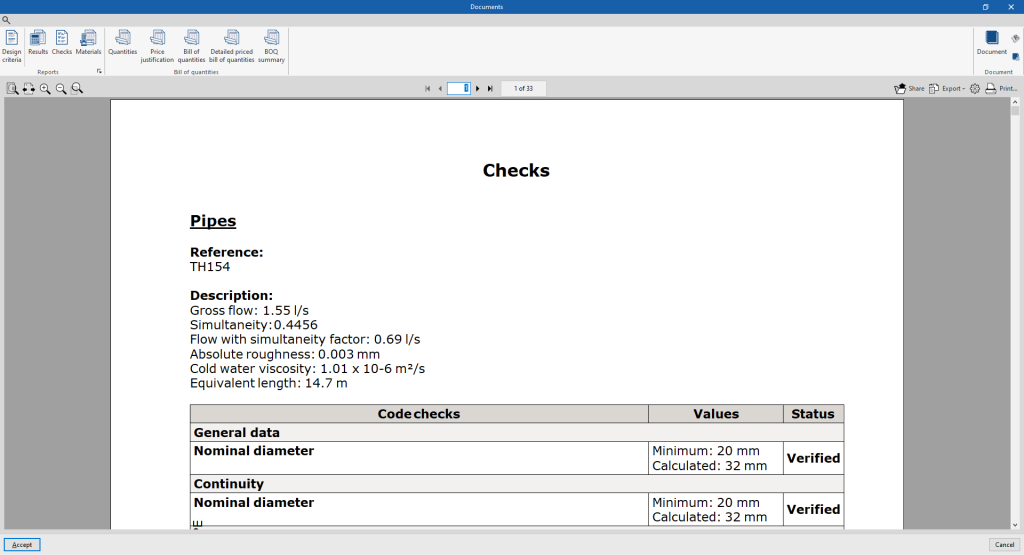

- Checks

Configures the information that appears in the check report.- Worst case span (optional)

- Most favourable span (optional)

- Fails (optional)

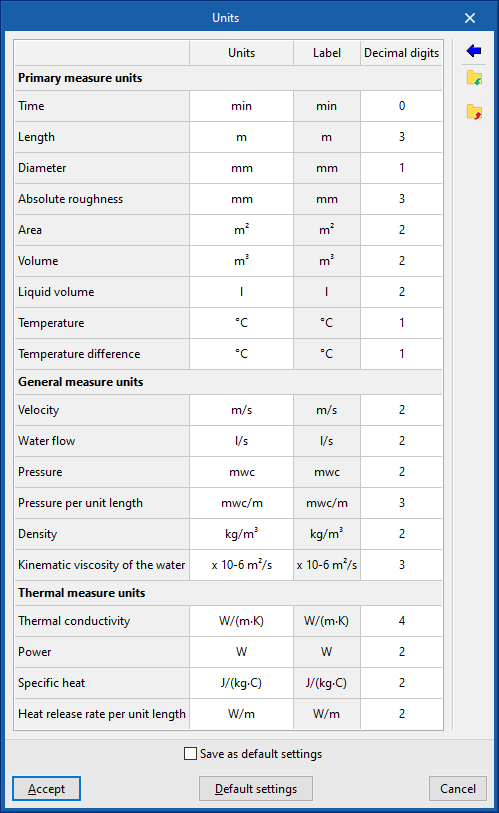

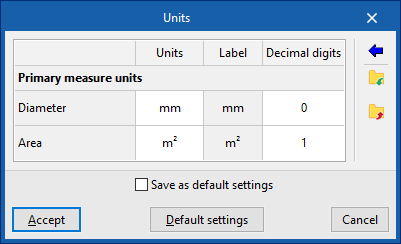

Units

Configures the units, the label and the number of decimal places for each of the magnitudes related to the water supply system:

- Primary measure units (Time, Length, Diameter, Absolute roughness, Area, Volume, Liquid volume, Temperature, Temperature difference)

- General measure units (Velocity, Water flow, Pressure, Pressure per unit length, Density, Kinematic viscosity of the water)

- Thermal measure units (Thermal conductivity, Power, Specific heat, Heat release rate per unit length)

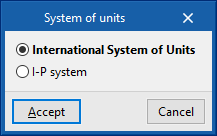

By using the "Import one of the predefined systems of units" option, available on the right-hand side of the panel, one of the following systems of units can be imported:

- International System of Units

Imports the units of the International System of Units. - I-P system

Imports the units of the I-P (Inch-Pound) or imperial system.

Selecting the materials and equipment for the water supply system

In the "Installation" tab of the "Water Systems" tab, in the "General options" from the "Project" group in the main toolbar, the "Material and equipment selection" of the following elements of the water supply system can be carried out:

- Tanks

- Booster sets

- Pumps

- Fittings

- Heat exchangers

- Instantaneous heaters

- Pipes catalogue

- Thermal insulation catalogue

By using the "Import configuration" option, available on the right-hand side of the "General options" panel, this data can be automatically generated for different national and international codes. It is also possible to import data from different manufacturers by clicking on the options showing their logo.

The other options in the right-hand column can be used to import and export the complete configuration of the "General options" panel to files on disk, as well as to select a file with initial values for creating a new job.

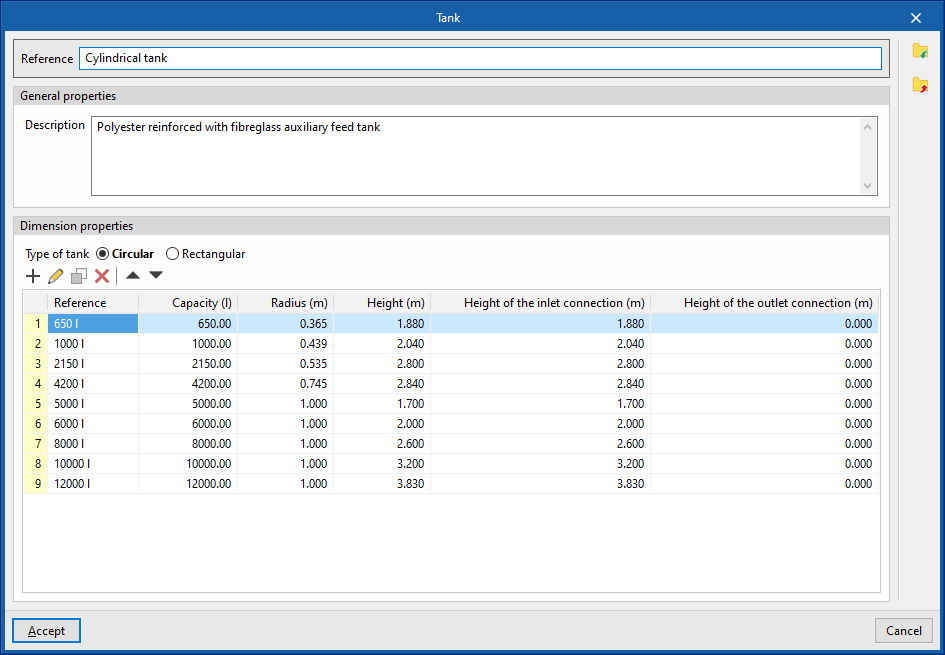

Tanks

Defines the materials and equipment corresponding to the tanks. The subsequent entry of these elements into the model is carried out by means of the "Tank" option in the "Water supply" group.

When defining the tanks in this section, the following parameters need to be entered:

- Reference

Material or equipment reference. - General properties

- Description

- Dimension properties

Enters the dimensional characteristics of the equipment available in the series by adding entries in the table.- Type of tank

The required dimensional characteristics vary depending on whether the tank is circular or rectangular.- Circular (Reference / Capacity / Radius / Height / Height of the inlet connection / Height of the outlet connection)

- Rectangular (Reference / Capacity / Radius / Height / Height of the inlet connection / Height of the outlet connection)

- Type of tank

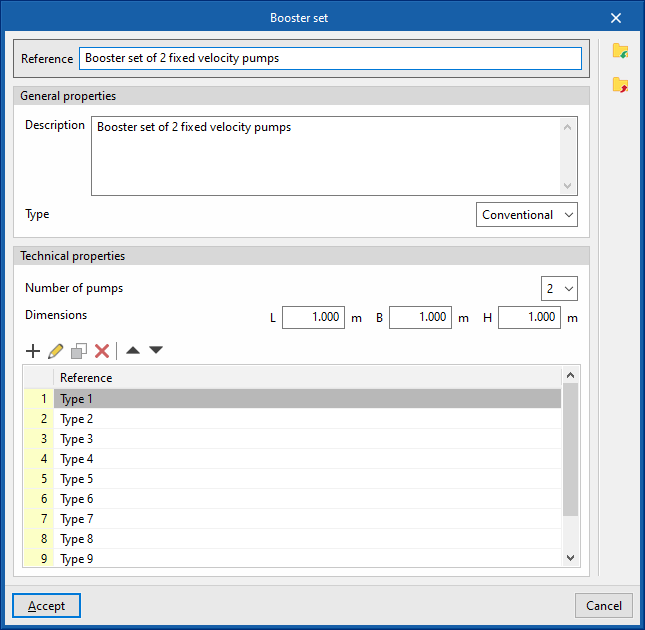

Booster set

Used to define the materials and equipment corresponding to the booster sets. These elements are subsequently entered into the model via the "Pumping system" option in the "Water supply" group.

When defining booster sets in this section, the following parameters need to be specified:

- Reference

Material or equipment reference. - General properties

- Description

- Type (Conventional / Variable flow)

- Technical properties

Enters the technical properties of the booster set.- Number of pumps (1 / 2 / 3 / 4)

- Dimensions (L, B, H)

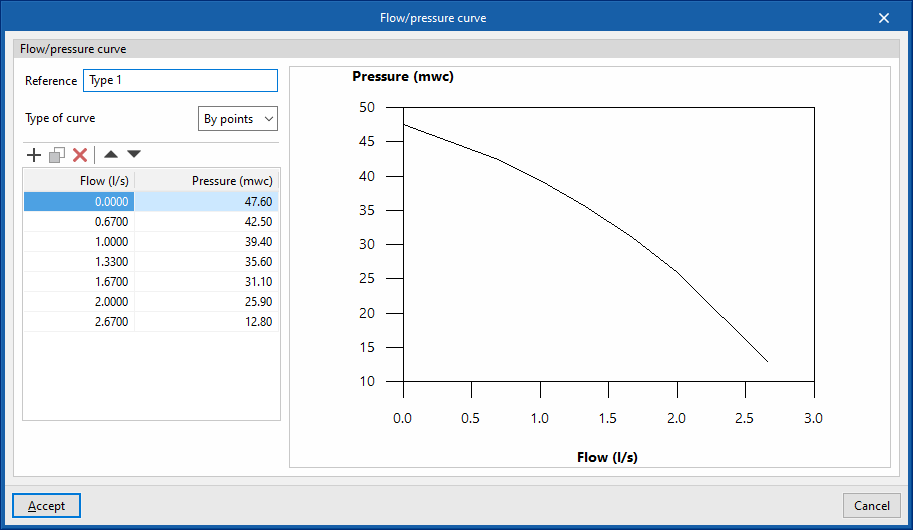

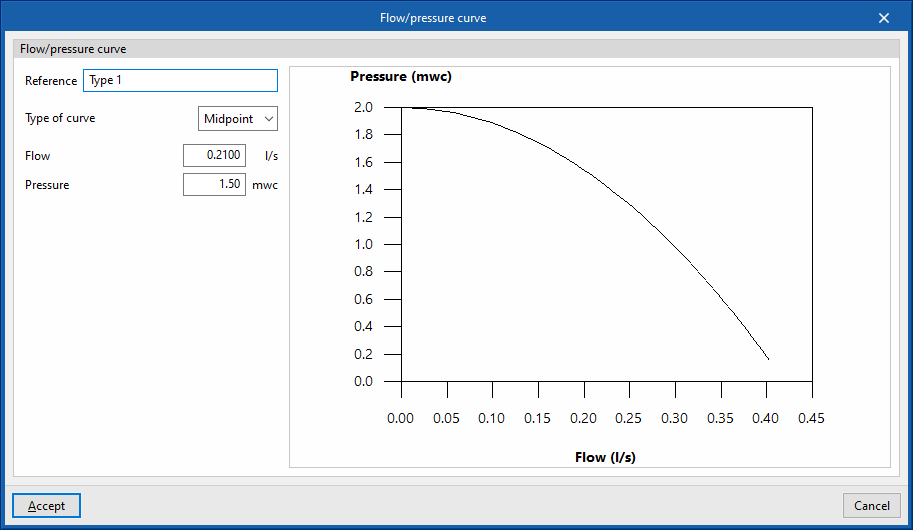

- Flow/Pressure curve

Used to define the available flow/pressure curves for the booster set by adding entries in the table.- Reference

Curve reference. - Type of curve

- Midpoint

Enters the values defining the midpoint of the flow/pressure curve and displays a graph with the associated curve.- Flow

- Pressure

- By points

Enters flow/pressure point pairs and displays a graph with the associated curve.- Flow

- Pressure

- Midpoint

- Reference

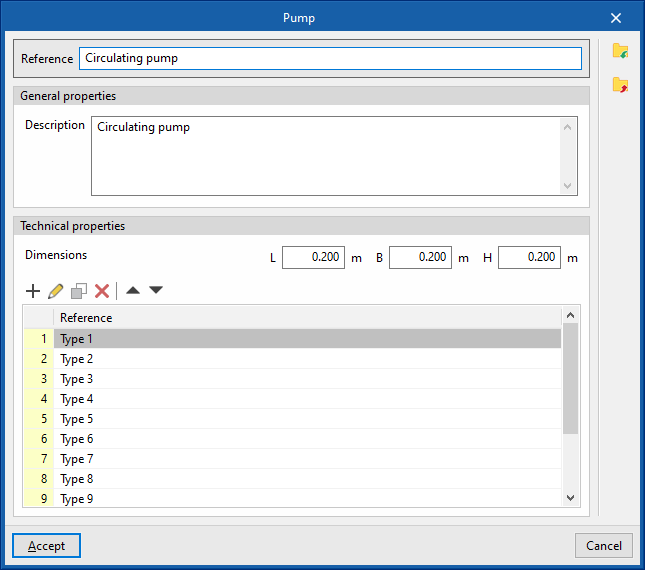

Pumps

Used to define the materials and equipment for the circulation pumps. These elements are subsequently entered into the model via the "Pumping system" option in the "Water supply" group.

When defining the circulation pumps in this section, the following parameters must be specified:

- Reference

Material or equipment reference. - General properties

- Description

- Technical properties

Enters the pump’s technical properties.- Dimensions (L, B, H)

- Flow/Pressure curve

Used to define the available flow/pressure curves for the booster set by adding entries in the table.- Reference

Curve reference. - Type of curve

- Midpoint

Enters the values defining the midpoint of the flow/pressure curve and displays a graph with the associated curve.- Flow

- Pressure

- By points

Enters flow/pressure point pairs and displays a graph with the associated curve.- Flow

- Pressure

- Midpoint

- Reference

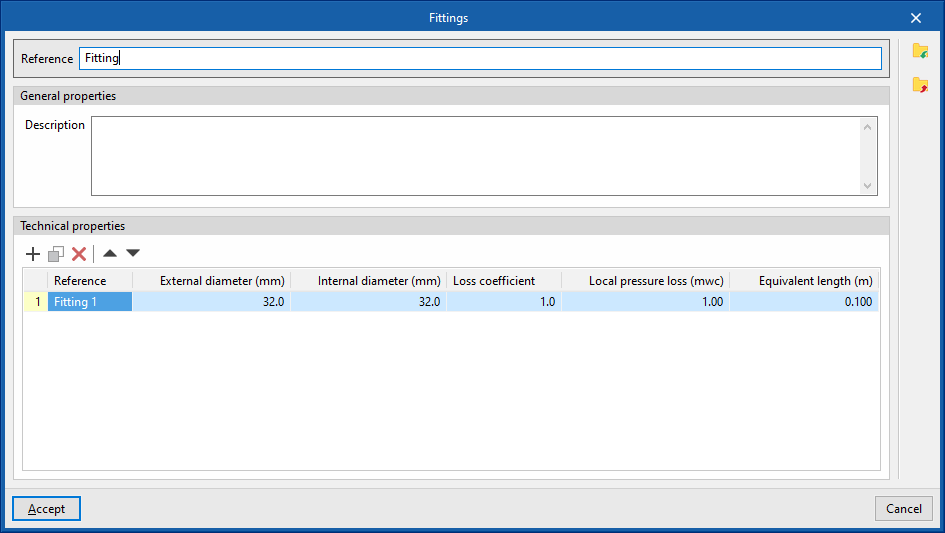

Fittings

Defines the materials and equipment corresponding to the fittings. The materials and equipment defined here can be assigned to the fittings created in "Fittings", in the "Design and check options to be carried out" section of the "General options". The subsequent entry of these elements in the model can be carried out via the "Fittings" option or via the options for automatically generating localised head losses, in the "Water supply" group.

When defining the fittings in this section, the following parameters must be specified:

- Reference

Material or equipment reference. - General properties

- Description

- Technical properties

Enters the technical properties of the fitting by adding entries in the table. The use of these factors depends on the "Local pressure loss calculation" criterion chosen for each fitting defined in "Fittings" in the "Design and check options to be carried out" section of the "General options".- Reference

- External diameter

- Internal diameter

- Loss coefficient

- Local pressure loss

- Equivalent length

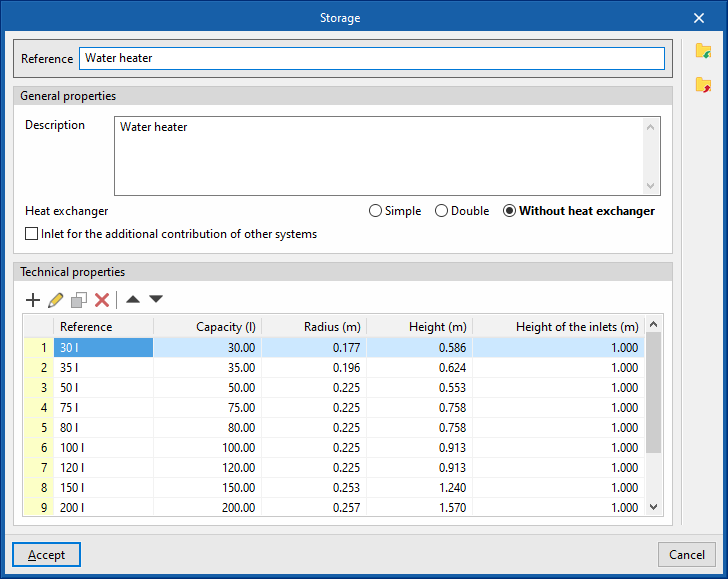

Storage tanks

Defines the materials and equipment corresponding to the storage tanks. The subsequent entry of these elements in the model can be carried out using the "Hot water production" option in the "Hot water" group.

When defining the storage tanks in this section, the following parameters must be specified:

- Reference

Material or equipment reference. - General properties

- Description

- Heat exchanger (Simple / Double/ Without heat exchanger)

- Inlet for the additional contribution of other systems

- Technical properties (Reference / Capacity / Radius / Height / Height of the inlets)

Enters the technical properties of the storage tanks of the series by adding entries in the table.

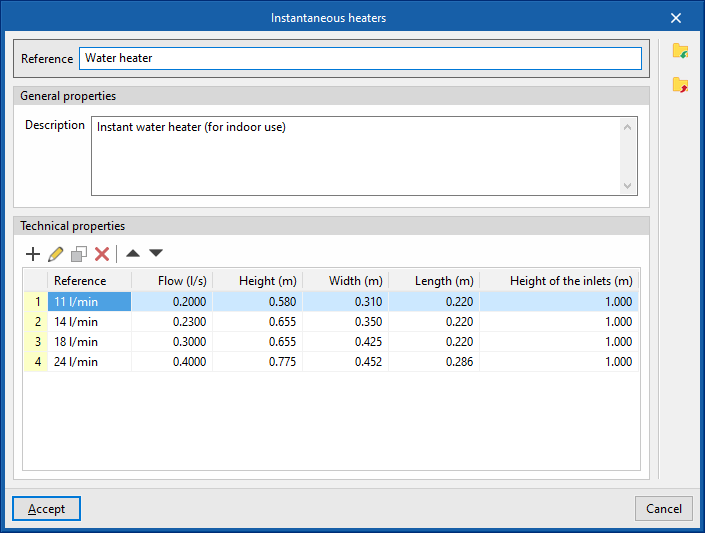

Instantaneous heaters

Defines the materials and equipment corresponding to the instantaneous heaters. The subsequent entry of these elements in the model can be carried out using the "Hot water production" option in the "Hot water" group.

When defining the instantaneous heaters in this section, the following parameters must be specified:

- Reference

Material or equipment reference. - General properties

- Description

- Technical properties (Reference / Flow / Height / Width / Length / Height of the inlets)

Enters the technical properties of the instantaneous heaters of the series by adding entries in the table.

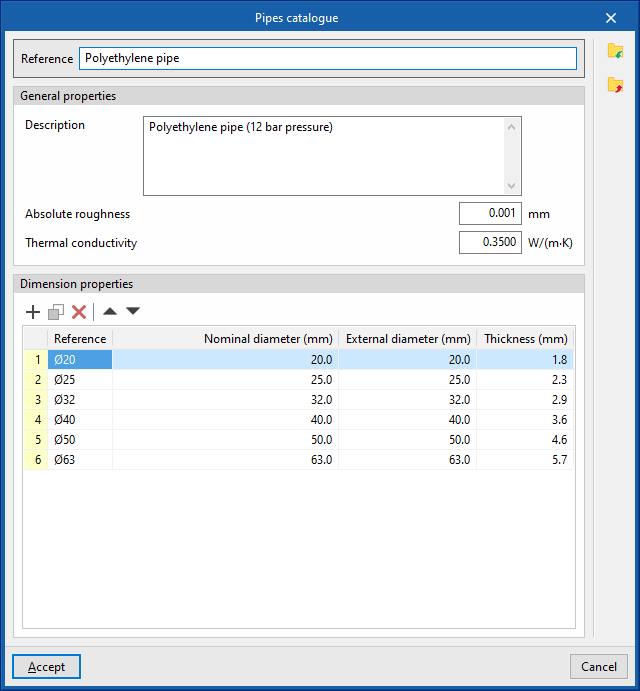

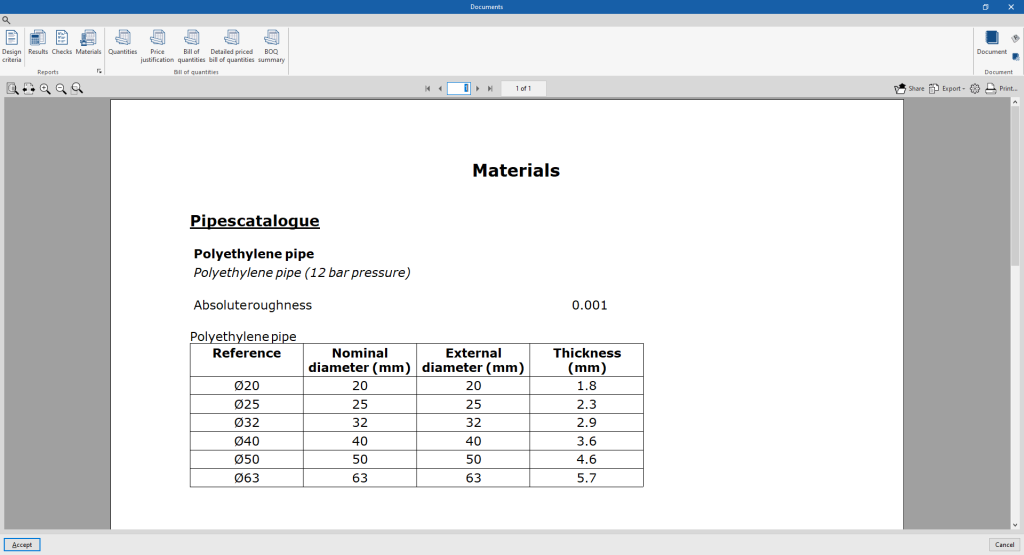

Pipes catalogue

Defines the catalogue of materials available for the pipes. The materials defined here can be assigned to the pipes created in "Pipes", in the "Design and check options to be carried out" section of the "General options". The subsequent entry of these elements in the model is carried out by means of the options available in the "Pipes" group.

When defining the pipes in this section, the following parameters must be specified:

- Reference

Material reference. - General properties

- Description

- Absolute roughness

- Thermal conductivity

- Dimension properties (Reference / Nominal diameter / External diameter / Thickness)

Enters the dimensional properties of each pipe of the series by adding entries in the table.

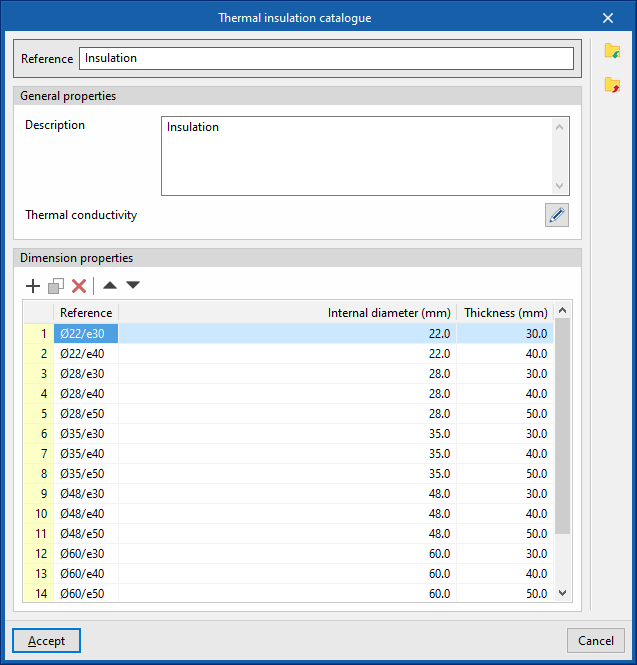

Thermal insulation catalogue

Defines the catalogue of materials available for the thermal insulation of pipes. The materials defined here can be assigned to the pipes created in "Pipes", in the "Design and check options to be carried out" section of the "General options". The subsequent entry of these elements in the model is carried out by means of the options available in the "Pipes" group.

When defining the thermal insulation in this section, the following parameters must be specified:

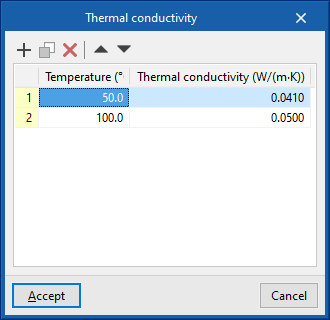

- Reference

Material reference. - General properties

- Description

- Thermal conductivity (Temperature / Conductivity)

In this section, a thermal conductivity value can be entered for each temperature value.

- Dimension properties (Reference / Internal diameter / Thickness)

Enters the dimensional properties of each thermal insulation of the series by adding entries in the table.

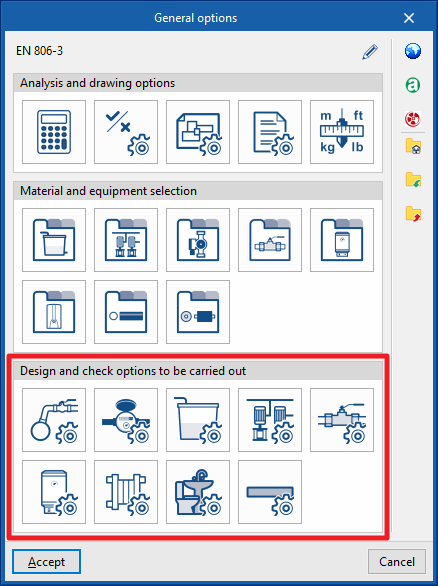

Setting the design and check options to be carried out on the water supply system

In the "Installation" tab of the "Water Systems" tab, in the "General options" of the "Project" group of the main toolbar, the "Design and check options to be carried out" can be defined for the following elements of the water supply system:

- Supply connection points

- Meters

- Tanks

- Pumping system

- Fitting

- Hot water production

- Heat exchangers

- Consumption

- Pipes

These criteria and option catalogues must be defined for each type of element before they are selected and entered into the model.

By using the "Import configuration" option, available on the right-hand side of the "General options" panel, this data can be automatically generated for different national and international standards. The data of different manufacturers can also be imported by clicking on the options displaying their logo.

The other options in the right-hand column allow the complete configuration of the "General options" panel to be imported and exported to files on disk, as well as selecting a file with initial values for creating a new job.

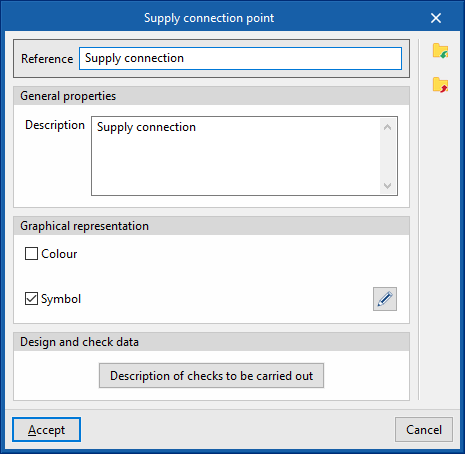

Supply connection point

Used to define the supply connection points available in the project. These elements are then entered in the model via the "Supply connection point" option in the "Water supply" group.

When defining a supply connection point, the following parameters must be specified:

- Reference

Supply connection point reference. - General properties

- Description

- Graphical representation

- Colour (optional)

- Symbol (optional)

- Design and check data

- Description of checks to be carried out

Used to enter a descriptive text of the checks to be carried out on the element. This text will appear in the reports next to each check.- Flow

- Pressure

- Description of checks to be carried out

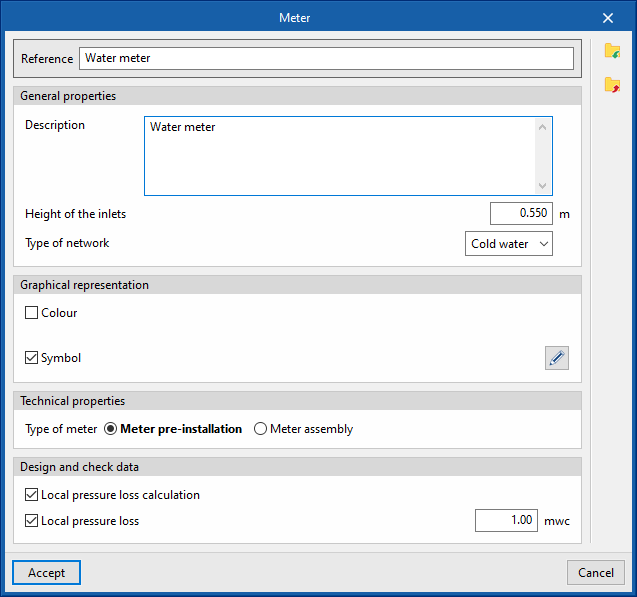

Meters

Used to define the meters available in the project. These elements are then entered in the model via the "Meter" option in the "Water supply" group.

When defining a meter, the following parameters must be specified:

- Reference

Meter reference. - General properties

- Description

- Height of the inlets

- Type of network (Cold water / Hot water)

- Graphical representation

- Colour (optional)

- Symbol (optional)

- Technical properties

- Type of meter

- Meter pre-installation

- Meter assembly

- Type of meter

- Design and check data

- Local pressure los calculation (optional)

Enters local pressure drop values for meters. - Local pressure loss (optional)

Defines a local pressure drop value associated with the meter type. If left deactivated, the local pressure drop must be defined for each particular element of the meter type.

- Local pressure los calculation (optional)

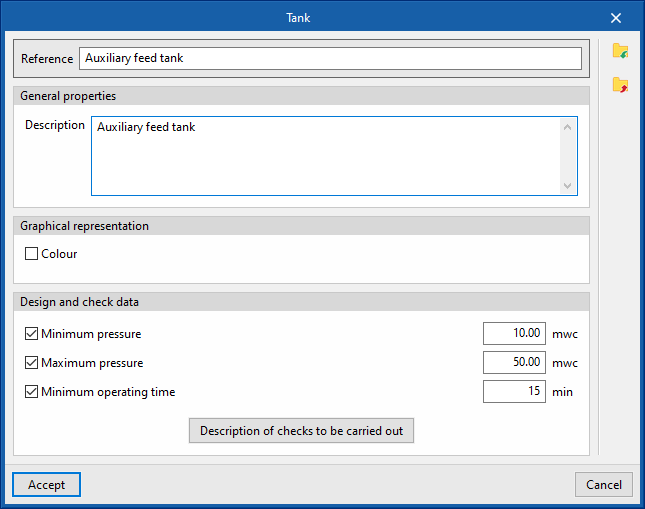

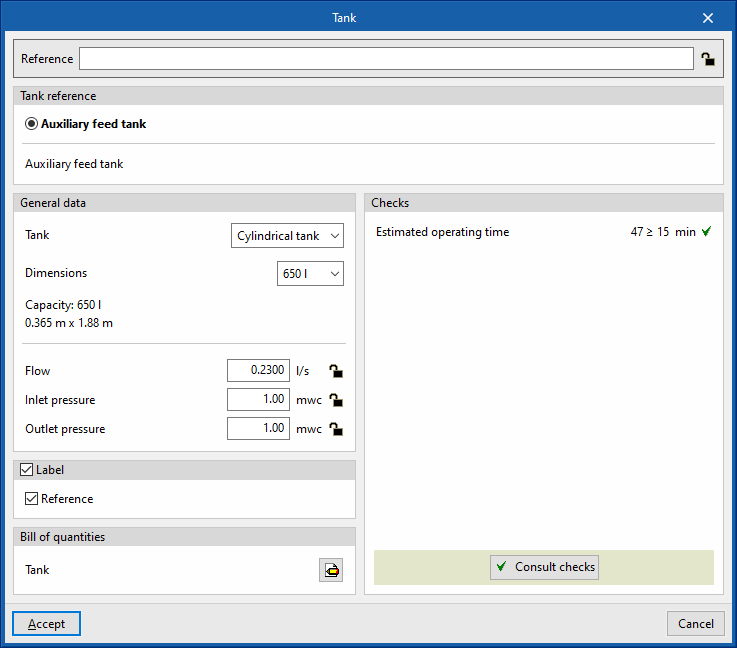

Tanks

Used to define the tanks available in the project. These elements are then entered in the model via the "Tank" option in the "Water supply" group.

When defining a tank, the following parameters must be specified:

- Reference

Tank reference. - General properties

- Description

- Graphical representation

- Colour (optional)

- Design and check data

- Minimum pressure (optional)

Minimum pressure required at the tank inlet. - Maximum pressure (optional)

Maximum pressure required at the tank inlet. - Minimum operating time (optional)

- Description of checks to be carried out

Used to enter a descriptive text of the checks to be carried out on the element. This text will appear in the reports next to each check.- Pressure

- Estimated operating time

- Minimum pressure (optional)

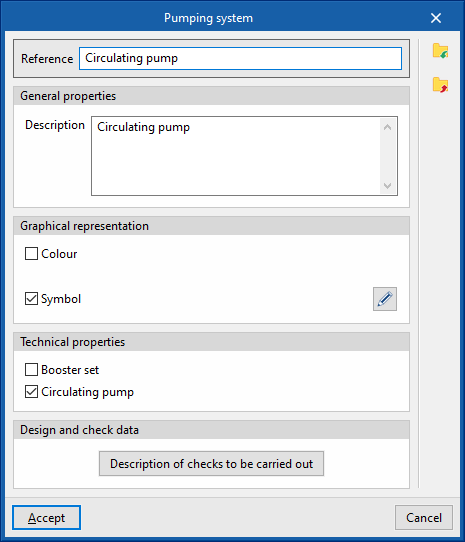

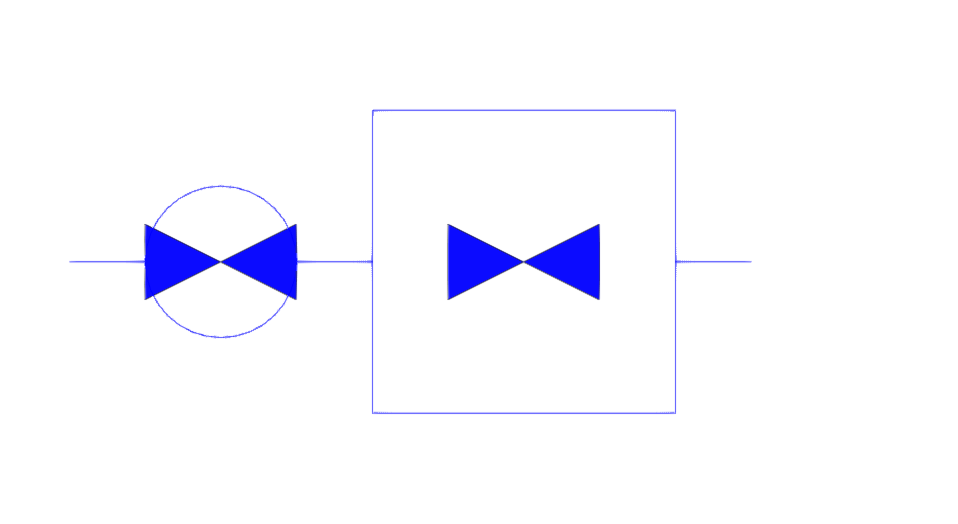

Pumping system

Used to define the pumping systems available in the project. These elements are then entered in the model via the "Pumping system" option in the "Water supply" group.

When defining a pumping, the following parameters must be specified:

- Reference

Pumping system reference. - General properties

- Description

- Graphical representation

- Colour (optional)

- Symbol (optional)

- Technical properties

Indicates whether the pumping system is a booster set or a circulation pump by activating the corresponding option.- Booster set (optional)

- Circulation pump (optional)

- Design and check data

- Description of checks to be carried out

Used to enter a descriptive text of the checks to be carried out on the element. This text will appear in the reports next to each check.- Pressure increase

- Description of checks to be carried out

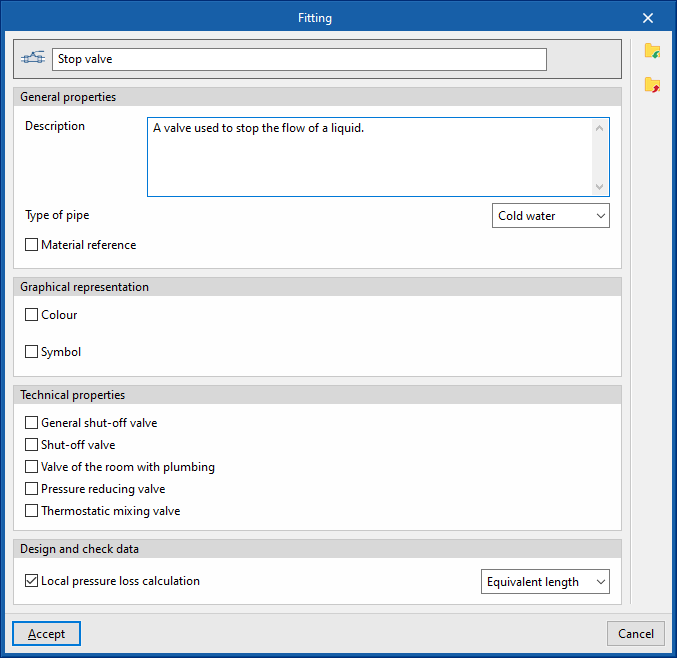

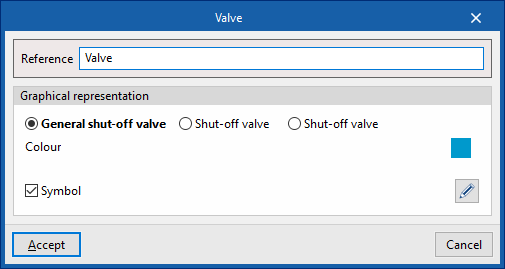

Fittings

Used to define the fittings and manifolds available in the project. The subsequent entry of these elements in the model can be done through the "Fitting" and "Manifold" options or through the options for the automatic generation of localised pressure losses, in the "Water supply" group.

"Fittings" tab

When defining a fitting, the following parameters must be specified:

- Reference

Fitting reference. The button on the left is used to change the associated "Icon" if this fitting is activated in the tool group. - General properties

- Description

- Type of pipe (Cold water / Hot water / Hot water return / Auxiliary supply / Auxiliary return)

- Material reference

Used to select one of the materials entered in the "Fittings" table, in the "Material and equipment selection" section of the "General options".

- Graphical representation

- Colour (optional)

- Symbol (optional)

- Technical properties

Indicates the type of fitting by checking the corresponding option from those available:- General shut-off valve (optional)

- Shut-off valve (optional)

- Valve of the room with plumbing (optional)

- Pressure reducing valve (optional)

- Thermostatic mixing valve (optional)

- Design and check data

- Local pressure loss calculation (optional)

Activates the calculation of localised pressure loss in the fitting and defines the calculation criterion by selecting it from those available:- Loss coefficient

- Local pressure loss

- Equivalent length

- Local pressure loss calculation (optional)

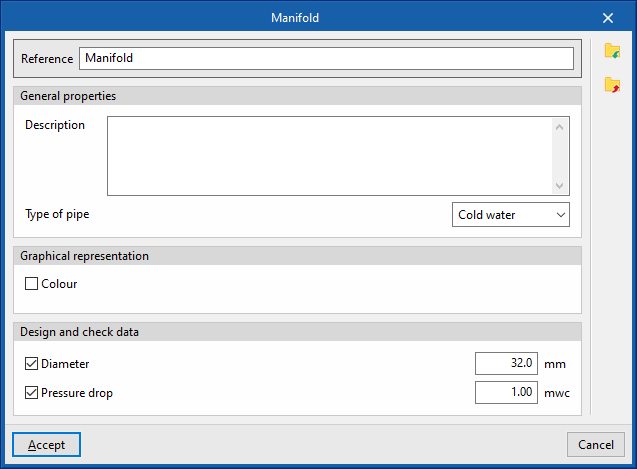

“Manifold” tab

When defining a manifold, the following parameters must be specified:

- Reference

Manifold reference. - General properties

- Description

- Type of pipe (Cold water / Hot water / Hot water return / Auxiliary supply / Auxiliary return)

- Graphical representation

- Colour (optional)

- Design and check data

- Diameter (optional)

Allows the diameter associated with the manifold to be defined. If this option is deactivated, the program requires this value to be entered for each element in the model. - Pressure drop (optional)

Defines the pressure loss associated with the manifold. If this option is deactivated, the program requires this value to be entered for each element in the model.

- Diameter (optional)

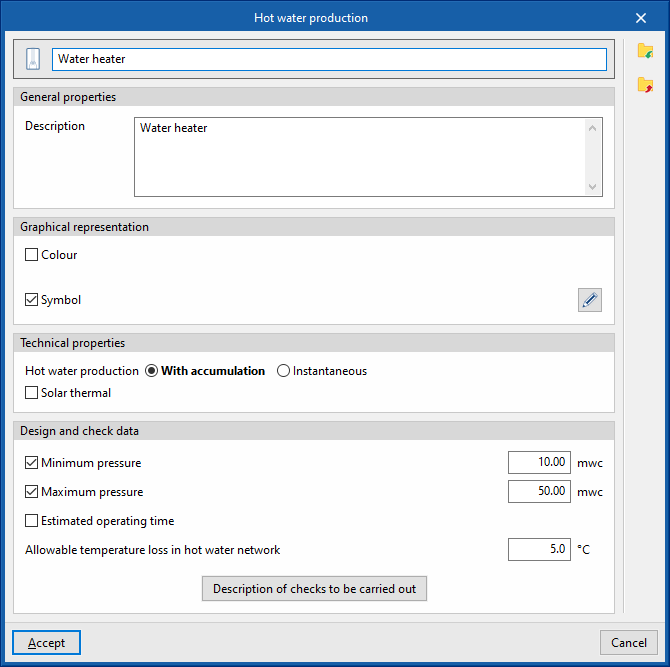

Hot water production

Used to define the hot water production systems available in the project. The subsequent entry of these elements in the model can be carried out by means of the "Hot water production" option, in the "Hot water" group.

When defining a hot water production system, the following parameters must be specified:

- Reference

Hot water production system reference. The button on the left changes the associated "Icon" if this system is activated in the tool group. - General properties

- Description

- Graphical representation

- Colour (optional)

- Symbol (optional)

- Technical properties

Specifies the technical characteristics of the hot water production system:- Hot water production (With accumulation / Instantaneous)

- Solar thermal

- Design and check data

- Minimum pressure (optional)

Minimum pressure required at the inlet of the hot water production system. - Maximum pressure (optional)

Maximum pressure required at the inlet of the hot water production system. - Estimated operating time (optional)

- Allowable temperature loss in hot water network

- Description of checks to be carried out

Used to enter a descriptive text of the checks to be carried out on the element. This text will appear in the reports next to each check.- Flow

- Pressure

- Estimated operating time

- Minimum pressure (optional)

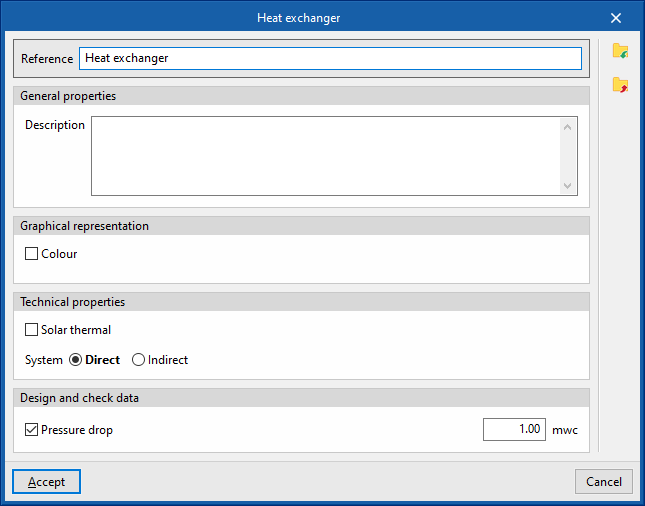

Heat exchangers

Used to define the heat exchangers available in the project. These elements are then entered in the model via the "Heat exchanger" option in the "Water supply" group.

When defining a heat exchanger, the following parameters must be specified:

- Reference

Heat exchanger reference. - General properties

- Description

- Graphical representation

- Colour (optional)

- Technical properties

Specifies the technical properties of the heat exchanger:- Solar thermal (optional)

- System (Direct / Indirect)

- Design and check data

- Pressure loss (optional)

Defines a pressure loss value associated with the type of heat exchanger.

- Pressure loss (optional)

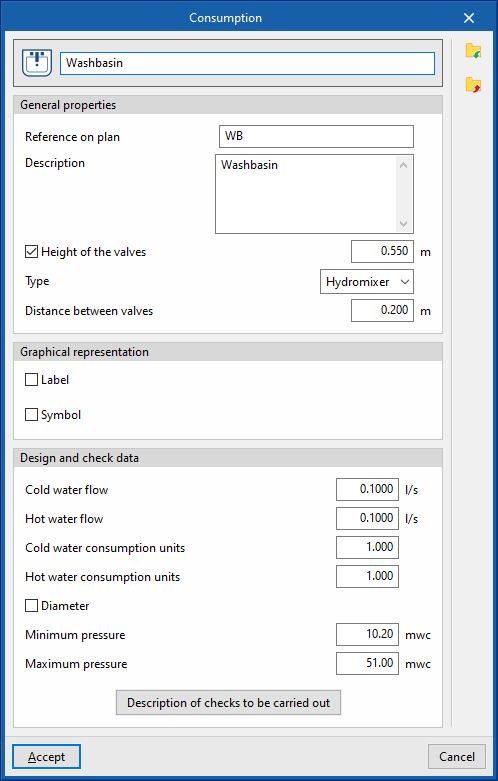

Consumption

Defines the consumptions available in the project. The subsequent entry of these elements in the model can be carried out by means of the "Consumption" option in the "Consumption" group.

When defining a consumption, the following parameters must be specified:

- Reference

Consumption reference. The button on the left can be used to change the associated "Icon" if this consumption is activated in the tool group. - General properties

- Reference on plan

- Description

- Height of the valves (optional)

- Type (Hydromixer / Cold water / Hot water)

- Distance between valves

- Graphical representation

- Label (optional)

- Reference (optional)

- Symbol (optional)

- Label (optional)

- Design and check data

- Cold water flow / Hot water flow (in “Hydromixer” consumption)

Cold and hot water flow rates required by consumption. - Flow (in “Cold water” or “Hot water” types of consumption)

Cold water flow rate or hot water flow rate required by consumption. - Diameter (optional)

- Minimum pressure

Minimum pressure required for consumption. - Maximum pressure

Maximum pressure required for consumption. - Description of checks to be carried out

Used to enter a descriptive text of the checks to be carried out on the element. This text will appear in the reports next to each check.- Pressure

- Cold water flow / Hot water flow (in “Hydromixer” consumption)

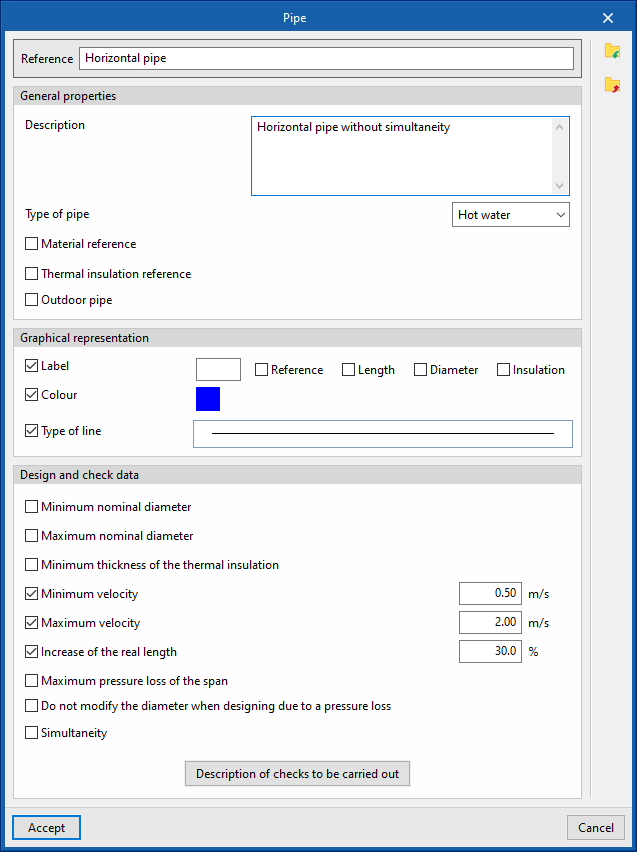

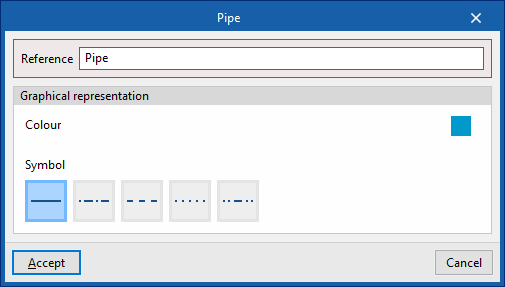

Pipes

Used to define the pipes available in the project. The subsequent entry of these elements into the model is carried out by means of the options available in the "Pipes" group.

When defining a pipe, the following parameters must be specified:

- Reference

Pipe reference. - General properties

- Description

- Type of pipe (Cold water / Hot water / Hot water return / Auxiliary supply / Auxiliary return)

- Material reference

Used to select one of the materials entered in the "Pipe catalogue" table, in the "Material and equipment selection" section of the "General options". - Thermal insulation reference

Used to select one of the materials entered in the "Thermal insulation catalogue" table, in the "Material and equipment selection" section of the "General options". - Outdoor pipe (optional)

Indicates that the pipe is located outdoors.

- Graphical representation

- Label (optional)

- Reference (optional)

- Length (optional)

- Diameter (optional)

- Insulation (optional)

- Symbol (optional)

- Colour (optional)

- Type of line (optional)

- Label (optional)

- Design and check data

- Minimum nominal diameter (optional)

Minimum allowable nominal diameter of the pipe. - Maximum nominal diameter (optional)

Minimum allowable nominal diameter of the pipe. - Minimum thickness of the thermal insulation (optional)

Minimum required thickness of thermal insulation. - Minimum velocity (optional)

Minimum permissible velocity of the fluid in the span. - Maximum velocity (optional)

Maximum permissible velocity of the fluid in the span. - Increase of the real length (optional)

Considers a percentage increase of the actual pipe length over the length entered in the model. - Maximum pressure loss of the span (optional)

Maximum allowable pressure loss of the pipe span. - Do not modify the diameter when designing due to a pressure loss (optional)

- Simultaneity (optional)

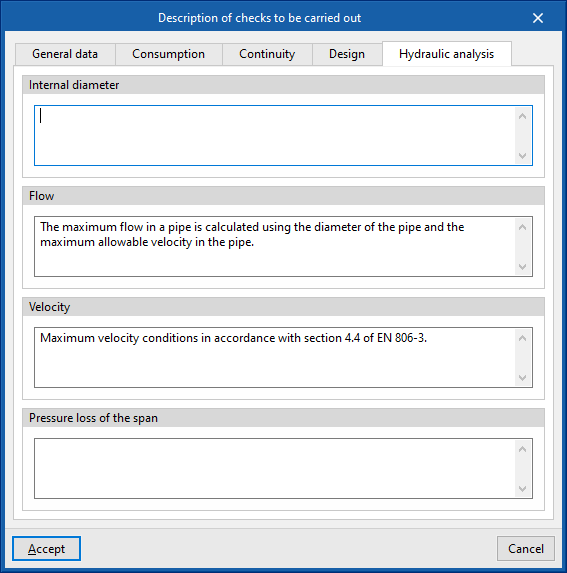

Selects one of the simultaneity design methods entered under "Simultaneity" in the "Design options" section of the "General options". - Description of checks to be carried out

Used to enter a descriptive text of the checks to be carried out on the element. This text will appear in the reports next to each check.- "General data" tab

- Internal diameter

- "Consumption" tab

- Internal diameter

- "Continuity" tab

- Diámetro nominal

- "Design" tab

- Internal diameter

- "Hydraulic" tab

- Internal diameter

- Flow

- Velocity

- Pressure loss of the span

- "General data" tab

- Minimum nominal diameter (optional)

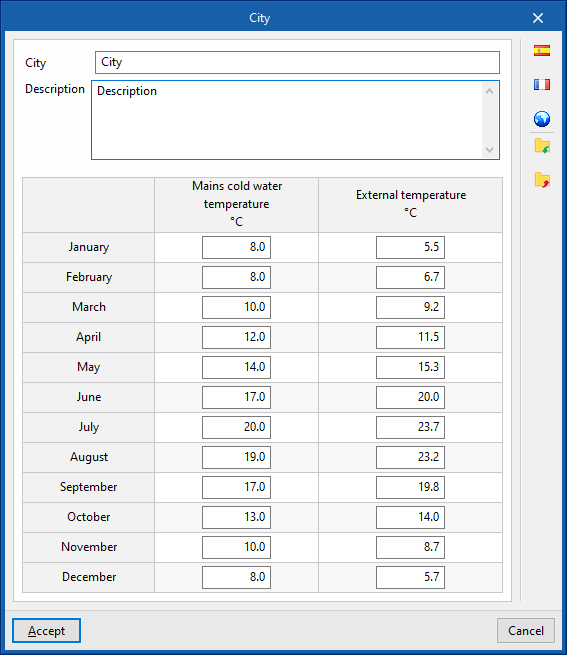

Defining the city in the water supply system project

In the "Installation" tab of the "Water Systems" tab, in the "General options" of the "Project" group of the main toolbar, there is an option for defining the city of the water supply system in the project:

City

Used to define the project site by specifying the following parameters:

- City

- Description

- Mains cold water temperature

Sets the mains cold water temperature for each month of the year. - External temperature

Defines the external temperature for each month of the year.

Assigning design options in the water supply system project

In the "Installation" tab of the "Water Systems" tab, in the "General options" of the "Project" group of the main toolbar, there is an option for defining the city of the water supply system in the project:

Design options

Selects one of the sets of design options previously defined in "Design options", accessible from the "General checks" button of the "General options" and assigns them globally to the desired element types.

Clicking on this option opens a window where users select a set of design options and the parameters defined therein are reported for the following categories of elements:

- Tank

- Hot water production

- Consumption

- Pipe

Then, the "Selection" button is used to access a table showing the currently defined parameters. Here the left box is ticked for each element type assigned to the selected set of design options. The program will modify the design parameters of these types after accepting this window.

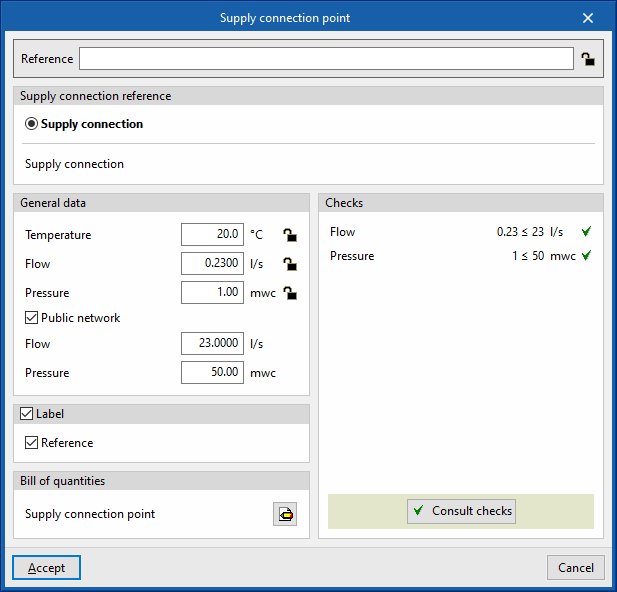

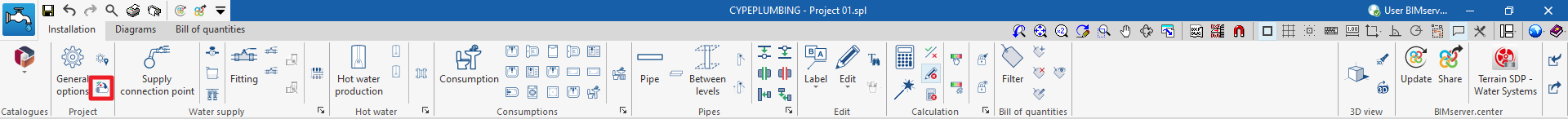

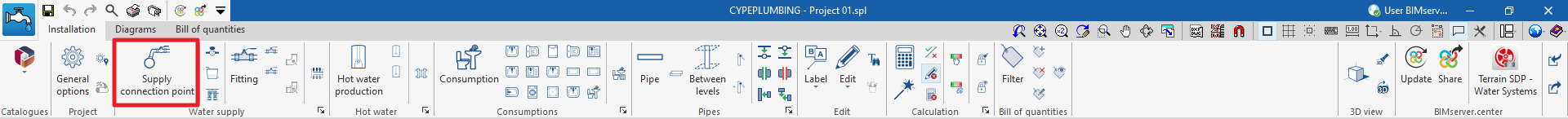

Entering supply connection points into the water supply system

Under “Installation” in the “Water Systems” tab, in the “Water supply” group of the main toolbar, there is an option for entering the supply connection points of the water supply system:

Supply connection point

Enters the supply connection points of the water supply system.

The following parameters can be configured when entering or editing a supply connection point. Some parameters only appear if the “Simplified entry” option in “Design options” under “General options” is deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Supply connection reference

The type of supply connection point can be selected by reference. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- Temperature (Lock/Unlock)

- Flow (Lock/Unlock)

- Pressure (Lock/Unlock)

- Public network (optional)

Indicates that the connection is to a public network. In this way, the available flow and pressure can be entered:- Flow

- Pressure

- 3D layout

The position and angle of the element can be defined. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

The information visible in the element's label can be managed.- Reference (optional)

- Bill of quantities

The element's bill of quantities generation can be controlled by filters.- Supply connection point

- Checks

The checks carried out on the element can be consulted and listed. The program will check that the flow and pressure data entered in the “Public network” section are enough to cover the values defined in the "General data" section.

These options are the same as those available under "Design and check options to be carried out" in "General options" in the "Project" group.

Entering elements from the water supply system: meters, tanks and pumping systems

In “Installation” under the “Water Systems” tab in the “Water supply” group of the main toolbar, the following elements of the water supply system can be entered:

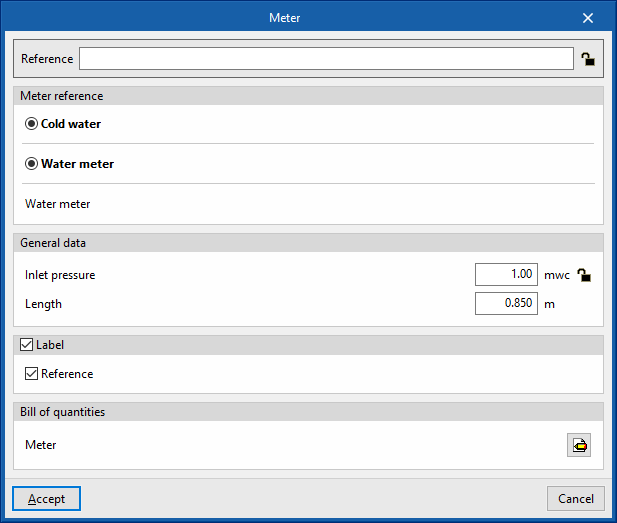

Meter

Inserts meters in the water supply system.

When entering or editing a meter, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option in "Design options" under "General options" is deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Meter reference

The type of meter can be selected by reference. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- Inlet pressure (Lock/Unlock)

Defines the meter’s inlet pressure. - Local pressure loss

Defines the local pressure drop value associated with a particular element. This option only appears if the “Local pressure loss calculation” option is activated in the type of meter defined in "Design and check options to be carried out"’ (in “General options”, in the “Project” group) while keeping the “Local pressure loss” option deactivated. - Length

Defines the length of the meter.

- Inlet pressure (Lock/Unlock)

- 3D layout

The position and angle of the element can be defined. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

The information visible in the element's label can be managed.- Reference (optional)

- Bill of quantities

The element's bill of quantities generation can be controlled by filters.- Meter

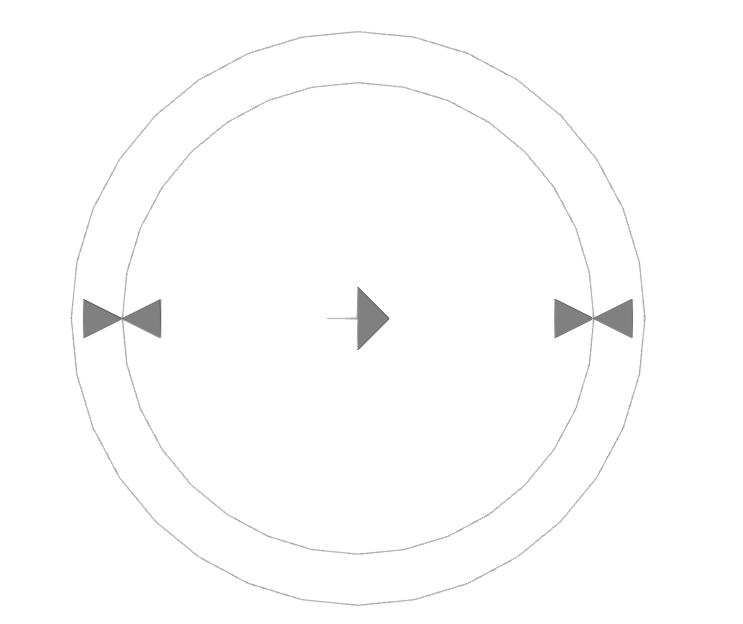

Tank

Inserts tanks into the water supply system.

When entering or editing a tank, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option in "Design options" under "General options" is kept deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Tank reference

The type of tank can be selected by reference. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- Tank

The material or equipment associated with the tank can be selected. The system materials and equipment can be created and edited in "Material and equipment selection" in "General options", in the "Project" group. - Dimensions

Selects the dimensions of the tank by entering its capacity. - Flow (Lock/Unlock)

Defines the element’s flow. - Inlet pressure (Lock/Unlock)

Defines the inlet pressure to the tank. - Outlet pressure (Lock/Unlock)

Defines the outlet pressure to the tank.

- Tank

- 3D layout

The position and angle of the element can be defined. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

The information visible in the element's label can be managed.- Reference (optional)

- Bill of quantities

The element's bill of quantities generation can be controlled by filters.- Tank

- Checks

The checks carried out on the element can be consulted and listed. The program will check that the flow and pressure data entered in the “Public network” section are enough to cover the values defined in the "General data" section.

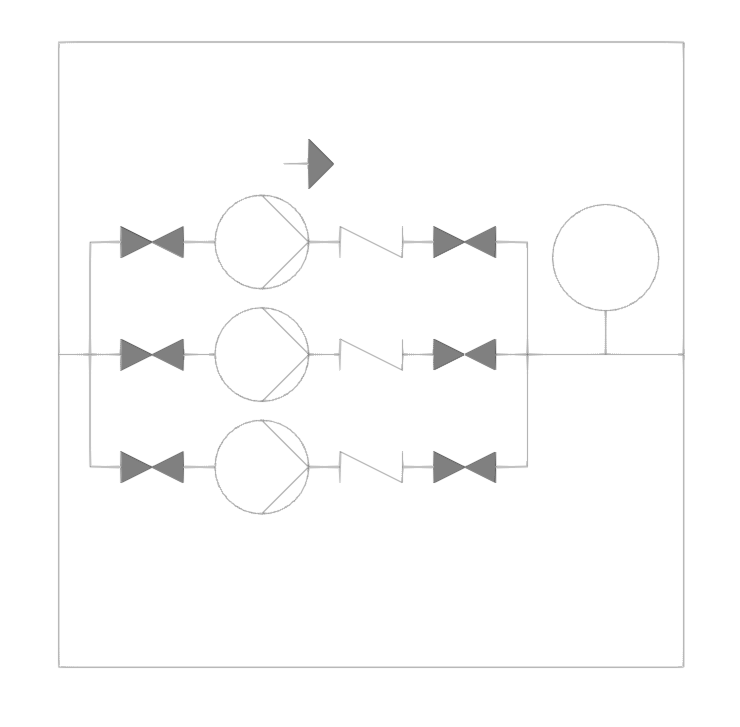

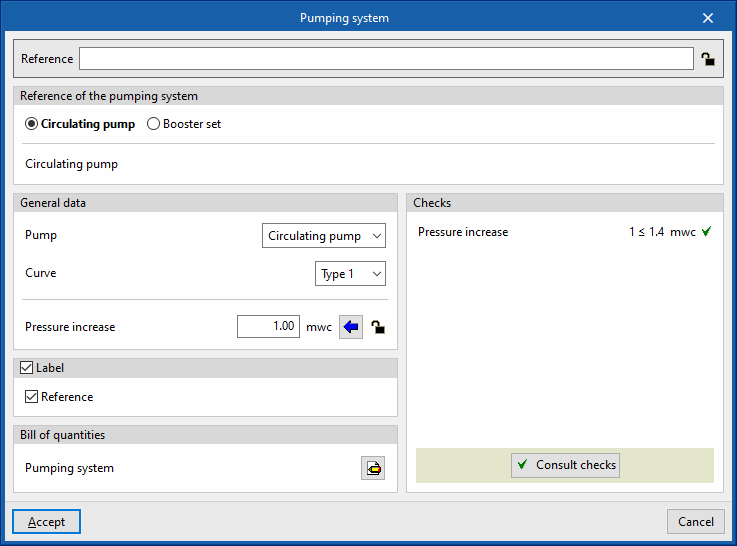

Pumping system

Enters pumping systems in the water supply system.

When entering or editing a pumping system, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option in "Design options" under "General options" is deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Pumping system reference

The type of pumping system can be selected by reference. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- For "Booster set" type pumping systems:

- Booster set

Selects the booster set. The system materials and equipment can be created and edited in "Material and equipment selection" in "General options". - Curve

Selects the booster set curve from those available. - Flow (Lock/Unlock)

Defines the element’s flow. - Inlet pressure (Lock/Unlock)

Defines the inlet pressure to the pumping system. - Outlet pressure (Lock/Unlock)

Defines the outlet pressure to the pumping system.

- Booster set

- For "Pumping system" type or generic pumping systems:

- Pump

Selects the circling pump. The system materials and equipment can be created and edited in "Material and equipment selection" in "General options". - Curve

Selects the pressure group curve from those available. - Total pressure rise (Lock/Unlock)

Defines the pressure increase in the pumping system. This value can be defined as the sum of the pressure drop per pipe section and the point pressure drop due to fittings by means of the button on the right-hand side.

- Pump

- For "Booster set" type pumping systems:

- 3D layout

The position and angle of the element can be defined. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

The information visible in the element's label can be managed.- Reference (optional)

- Bill of quantities

The element's bill of quantities generation can be controlled by filters.- Pumping system

- Checks

The checks carried out on the element can be consulted and listed. The program will check that the flow and pressure data entered in the “Public network” section are enough to cover the values defined in the "General data" section.

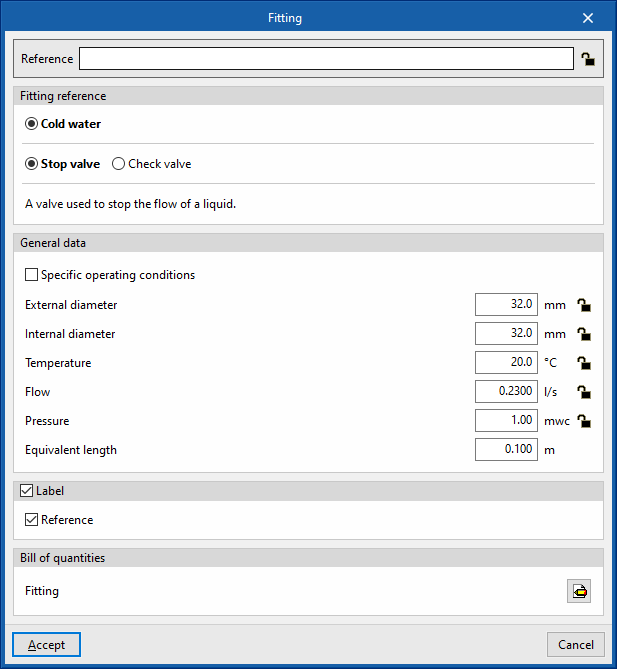

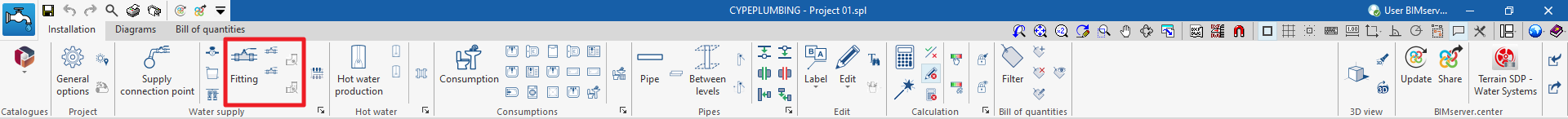

Entering fittings into the water supply system and generating localised pressure drops at pipe joints

In “Installation” under the “Water Systems” tab in the “Water supply” group of the main toolbar, the following elements of the water supply system can be entered:

Fitting

Inserts fittings into the water supply system.

When entering or editing a fitting, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option in "Design options" under "General options" is deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Fitting reference

Selects the type of fitting by its reference and depending on whether it is located in a "Cold water", "Hot water", "Hot water return", "Auxiliary supply" or "Auxiliary return" pipe. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- Specified operating conditions (optional) (Start of the installation / End of the installation)

- Diameter (Lock/Unlock)

Selects the technical characteristics of the pipe associated with the fitting. This option only appears if the “Material reference” option is activated in the type of fitting defined in "Design and check options to be carried out" in "General options", in the "Project" group. - External diameter / Internal diameter (Lock/Unlock)

These options only appear if the “Material reference” option is activated in the type of fitting defined in "Design and check options to be carried out" in "General options", in the "Project" group. - Temperature (Lock/Unlock)

- Flow (Lock/Unlock)

- Pressure (Lock/Unlock)

- Loss coefficient / Local pressure loss / Equivalent length

Defines the value of the loss coefficient, the local pressure loss or the equivalent length associated with the element. These options only appear if the “Material reference” option is activated in the type of fitting defined in "Design and check options to be carried out" in "General options", in the "Project" group.

- 3D layout

The position and angle of the element can be defined. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

The information visible in the element's label can be managed.- Reference (optional)

- Bill of quantities

The element's bill of quantities generation can be controlled by filters.- Fitting

These options are equivalent to those available in "Design and check options to be carried out" in "General options", in the "Project" group.

Fittings with a checked box will be available as additional quick-access options in this tool group. This allows users to enter the desired fittings quickly.

Generating local pressure losses in pipe joints

The program includes two tools for the automatic generation of "Localised pressure drops in pipe joints":

- The first option generates pressure losses at the joints of all the pipes in the job.

- The second option generates the pressure losses at the pipe joints selected by the user.

After using any of these tools, the program reports the number of intersections where a localised pressure loss has been generated. From here, users can edit or delete the fittings created in the process if they wish to do so.

For these options to be available, the corresponding boxes must be activated in "Localised pressure drops in pipe joints" found in “Generation” under “Design options”, and in turn, under "General options". From here it is also possible to configure the type of fitting associated with each type of pipe joint.

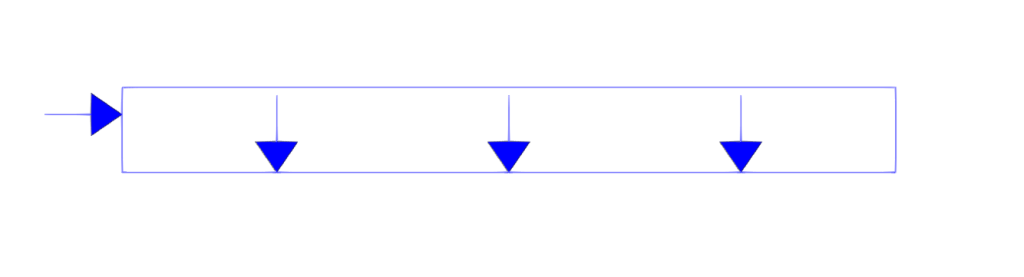

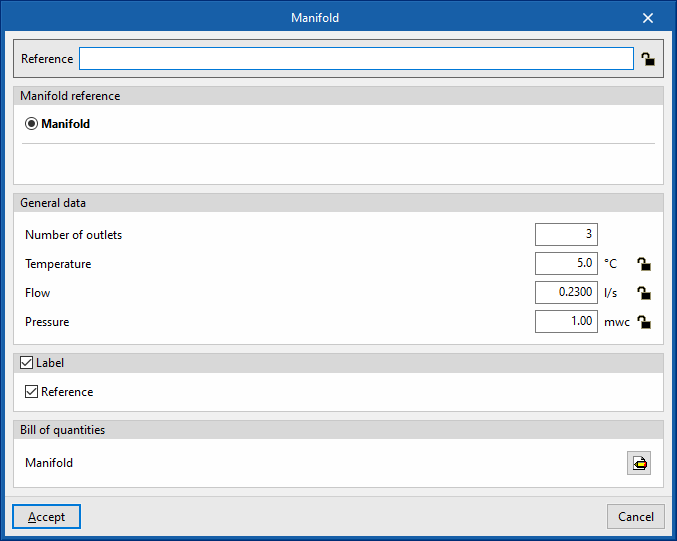

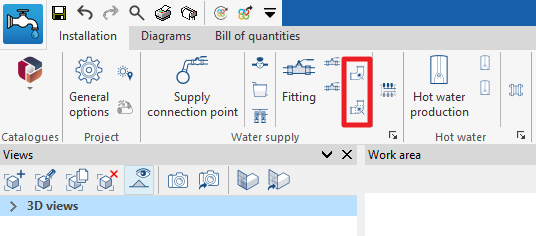

Entering manifolds in the water supply system

In the "Installation" tab under "Water Systems", in the "Water supply" group of the main toolbar, there is an option for entering manifolds in the water supply system:

Manifolds

This allows manifolds to be inserted into the water supply system.

When entering or editing a manifold, the following parameters can be configured. Some of them only appear if the ‘Simplified input’ option, which can be found in ‘Calculation options’ under ‘General options’, is deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Manifold reference

Selects the type of manifold by its reference. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- Number of outlets

- Diameter (Lock/Unlock)

Selects the technical characteristics of the pipe associated with the fitting. This option only appears if the “Diameter” option is deactivated in the manifold selected and defined in "Design and check options to be carried out" in "General options", in the "Project" group. - Temperature (Lock/Unlock)

- Flow (Lock/Unlock)

- Pressure (Lock/Unlock)

- Local pressure loss

Defines the value of the local pressure loss associated with the element. This option only appears if the “Pressure loss” option is activated in the manifold selected and defined in "Design and check options to be carried out" in "General options", in the "Project" group.

- 3D layout

The position and angle of the element can be defined. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

The information visible in the element's label can be managed.- Reference (optional)

- Bill of quantities

The element's bill of quantities generation can be controlled by filters.- Manifold

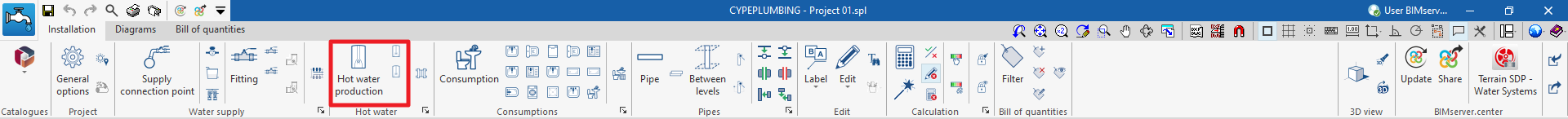

Entering domestic hot water production equipment in the water supply system

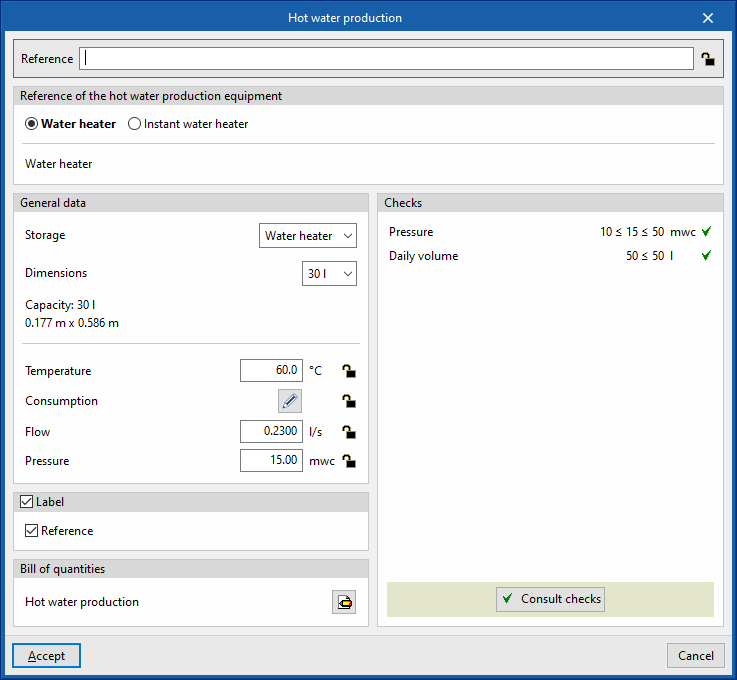

In the "Installation" tab of the "Water Systems" tab, in the "Hot water" group of the main toolbar, there is an option for inserting domestic hot water (DHW) production equipment into the water supply system:

Hot water production

Enters domestic hot water production equipment into the water supply system.

When entering or editing DHW production equipment, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option, which can be found in "Calculation options" under "General options", is deactivated:

- Reference

Element reference. This value can be locked or unlocked. If unlocked, the program will create or modify the reference when updating the results. - Reference of the hot water production equipment

The type of DHW production equipment can be selected by its reference. These types can be created and edited by means of "Design and check options to be carried out", which can be found in "General options", in the "Project" group. - General data

Defines the general data of the element. Some of these values can be locked or unlocked. If a value is locked, when updating the results it is not modified but remains unchanged.- Storage tank / Instant water heater

Selects the DHW production equipment from those defined in "Material and equipment selection", under "General options", in the "Project" group. - Dimensions (Lock / Unlock)

Selects the dimensions of the DHW production equipment by entering the capacity (in the case of storage heaters) or the flow rate (in the case of instant heaters). - Temperature (Lock / Unlock)

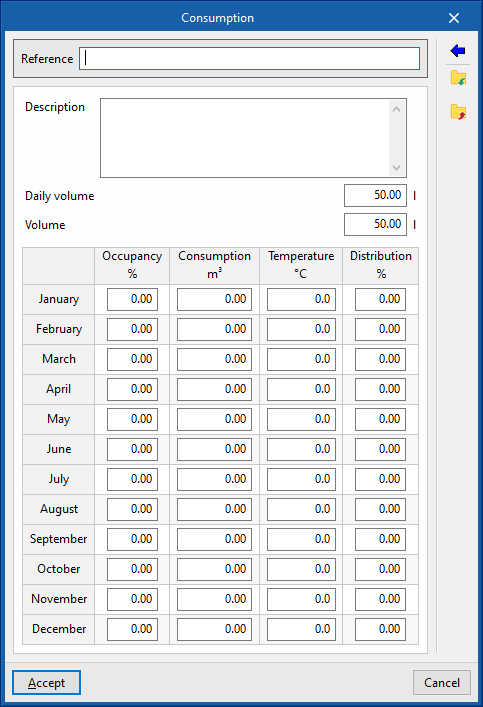

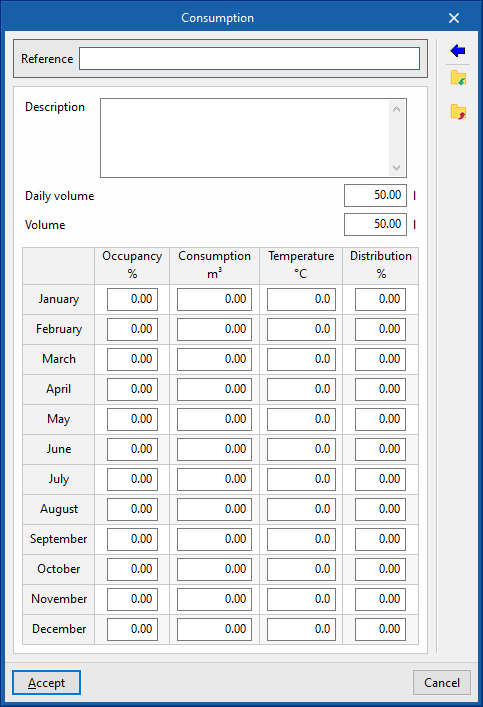

- Consumption

Defines the DHW consumption associated with the production equipment. With the button on the right-hand side, this data can be loaded from the values indicated for "Daily demand, per unit" (which can be configured in "Demand criteria", under "Analysis options" and, in turn, under "General options") and the number of "Units" provided by the equipment.- Reference

- Description

- Daily volume

- Volume

- Occupancy / Consumption / Temperature / Distribution

They are defined for each month.

- Flow (Lock / Unlock)

- Pressure (Lock / Unlock)

- Storage tank / Instant water heater

- 3D layout

Defines the position and angle of the element. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

Manages the information visible in the element's label.- Reference

- Bill of quantities

Controls the generation of the element's bill of quantities by means of filters.- Hot water production

- Consult checks

Allows the checks carried out on the element to be consulted and listed. These checks can be activated, edited or deactivated in "Design and check options to be carried out", under "General options" in the "Project" group.

These options are equivalent to those available in "Design and check options to be carried out" under "General options" in the "Project" group.

The hot water production equipment with the checked box will be available as additional quick access options in this tool group. This allows users to quickly enter the desired equipment.

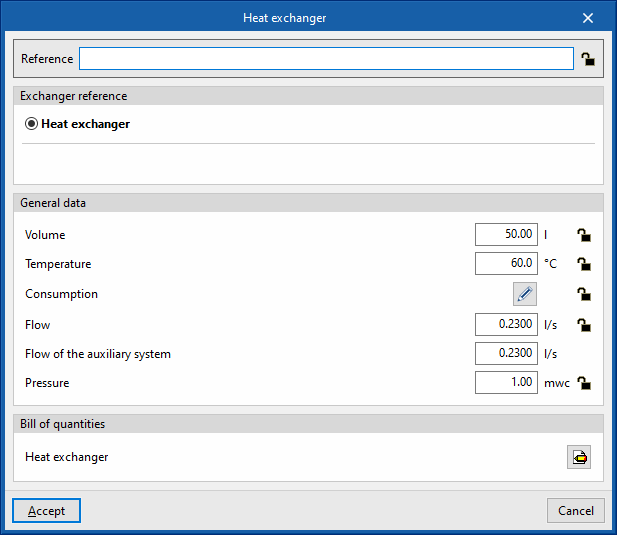

Entering heat exchangers in the water supply system

In the "Installation" tab of the "Water Systems" tab, in the "Hot water" group of the main toolbar, there is an option for inserting heat exchangers into the water supply system:

Heat exchanger

Used to insert heat exchangers into the water supply system.

When entering or editing a heat exchanger, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option under "Design options" in "General options" is deactivated:

- Reference

Element reference. This value can be locked or unlocked. The program will create or modify the reference when updating results if unlocked. - Heat exchanger reference

The type of heat exchanger can be selected by reference. These types can be created and edited from "Design and check options to be carried out" in "General options", in the "Project" group. - General data

The element's general data can be defined. Some of these values can be locked or unlocked. If a value is locked when updating the results, it is not modified and remains unchanged.- Volume (Lock/Unlock)

- Temperature (Lock/Unlock)

- Consumption

Defines the DHW consumption associated with the production equipment. With the button on the right-hand side, this data can be loaded from the values indicated for "Daily demand, per unit" (which can be configured in "Demand criteria", under "Analysis options" and, in turn, under "General options") and the number of "Units" provided by the equipment.- Reference

- Description

- Daily volume

- Volume

- Occupancy / Consumption / Temperature / Distribution

They are defined for each month.

- Flow (Lock / Unlock)

- Flow of the auxiliary system

- Pressure (Lock / Unlock)

- 3D layout

Defines the position and angle of the element. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Bill of quantities

Controls the generation of the element's bill of quantities by means of filters.- Heat exchanger

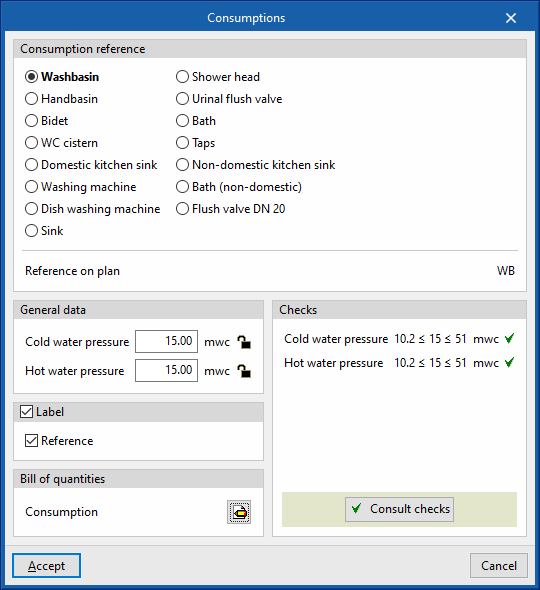

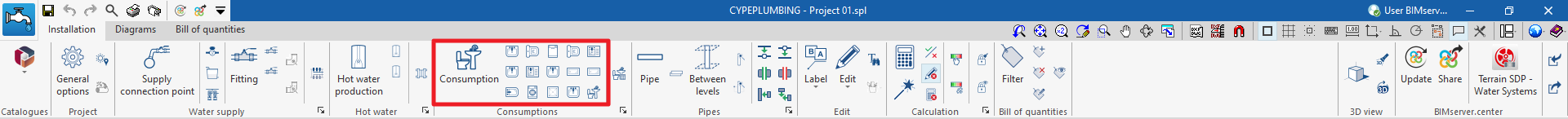

Entering consumptions in the water supply system

In the "Installation" tab within the "Water Systems" tab, in the "Consumption" group of the main toolbar, there are options for entering the consumption of the water supply system:

Consumption

This is used to enter consumptions in the water supply system.

When entering or editing a consumption, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option, which is accessed via "Calculation options" in the "General options", is deactivated:

- Consumption reference

Selects the type of consumption by its reference. These types can be created and edited in the "Design and checks to be carried out" section of the "General options" of the "Project" group. The program also provides information on their "Reference on plan". - General data

Permite definir los datos generales del elemento. Algunos de estos valores se pueden bloquear o desbloquear. Si un valor está bloqueado, aUsed to define the general data of the element. Some of these values can be locked or unlocked. If a value is locked, it is not modified when updating the results and remains unchanged.- Cold water pressure (Lock/Unlock)

Sets the cold water pressure in the consumption. This option appears in "Hydromixer" or "Cold water" type consumptions. - Hot water pressure (Lock/Unlock)

Sets the hot water pressure in the consumption. This option appears in "Hydromixer" or "Cold water" type consumptions.

- Cold water pressure (Lock/Unlock)

- 3D layout

Sets the position and angle of the element. This section only appears when editing a previously entered element.- Position (x, y, z)

- Angle

- Label (optional)

Manages the information visible in the element's label.- Reference

- Bill of quantities

Controls the generation of the element's bill of quantities using filters.- Consumption

- Consult checks

Used to consult and list the checks carried out on the element. These checks can be activated, edited or deactivated from "Design and check options to be carried out", in the "General options" of the "Project" group.

These options are equivalent to those available in the "Design and check options to be carried out" section, within the "General options" of the "Project" group.

Consumptions with a checked box will be available as additional quick-access options in this tool group. This allows for quick entry of the desired consumptions.

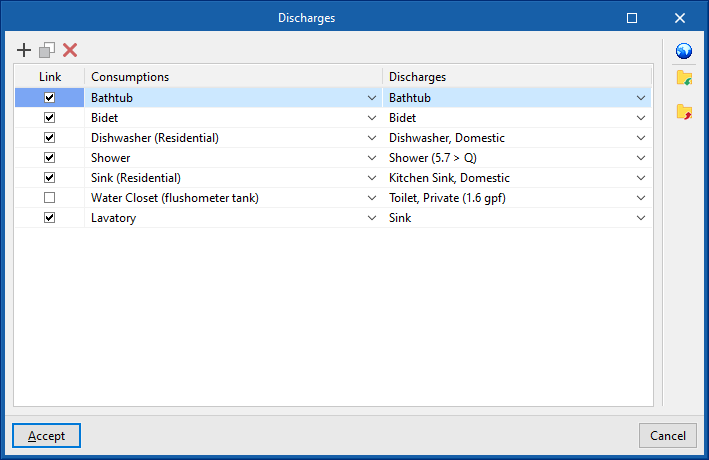

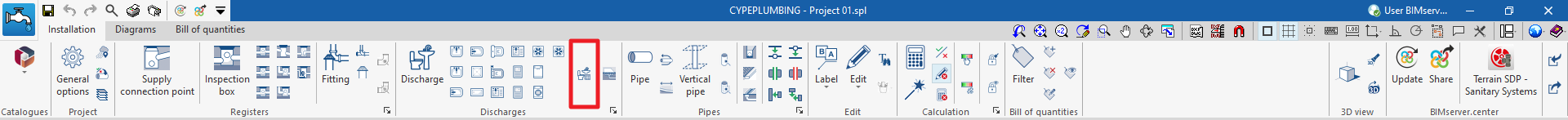

Coordination between consumptions and discharges in water supply and evacuation systems

In the "Installation" tab within the "Water Systems" tab, in the "Consumption" group of the main toolbar, there is an option that can be used to coordinate consumption and discharges in the water supply and evacuation systems:

This feature is equivalent to the one found under the "Installation" tab of the "Sanitary Systems" tab in the "Discharges" group of the main toolbar:

Clicking on the option opens a window that displays a table with three columns:

- Link

- Consumptions

- Discharges

The consumption associated with each discharge can be defined in the program by selecting it in each of the entries in the table. This way, when a consumption is entered in the "Water Systems" tab, the associated discharge is automatically entered in the "Sanitary Systems" tab, and vice versa, when a discharge is entered in the "Sanitary Systems" tab, the associated consumption is automatically entered in the "Water Systems" tab.

If the "Link" checkbox is ticked, the associated consumption and discharge will remain linked for editing operations such as moving them. Thus, moving the consumption will also move the discharge.

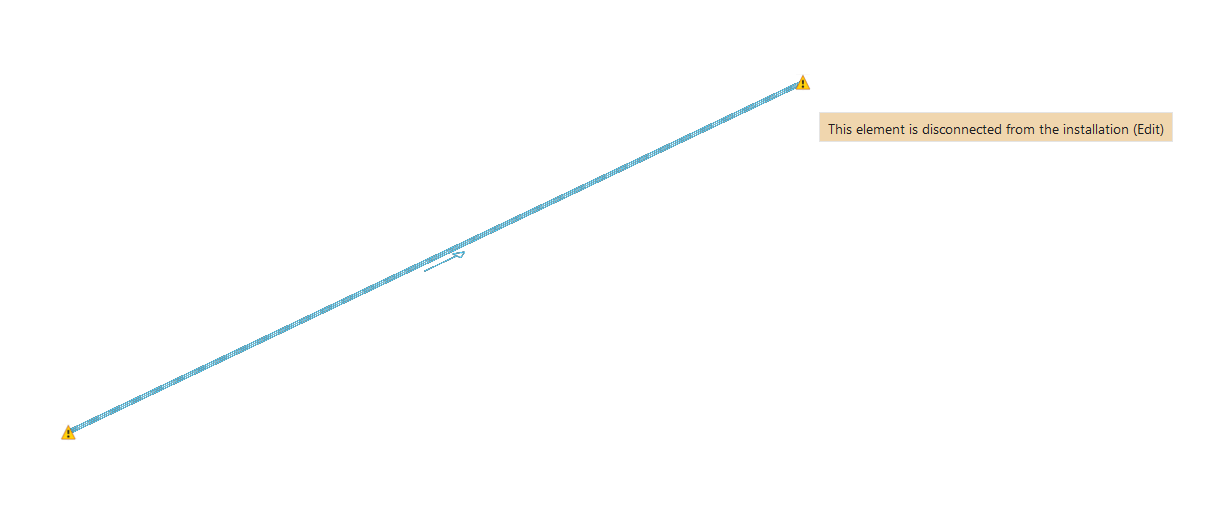

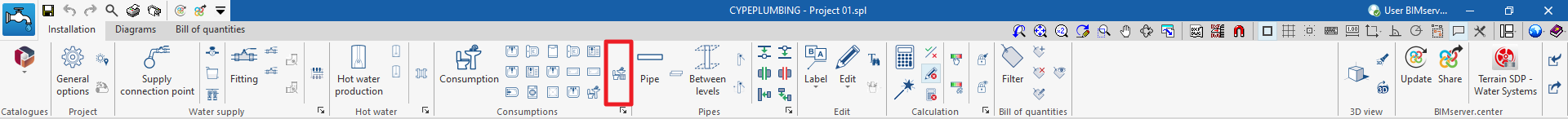

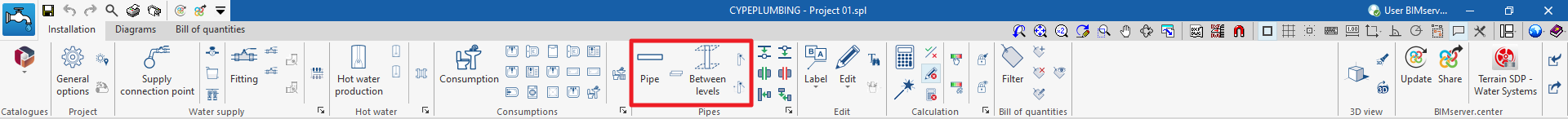

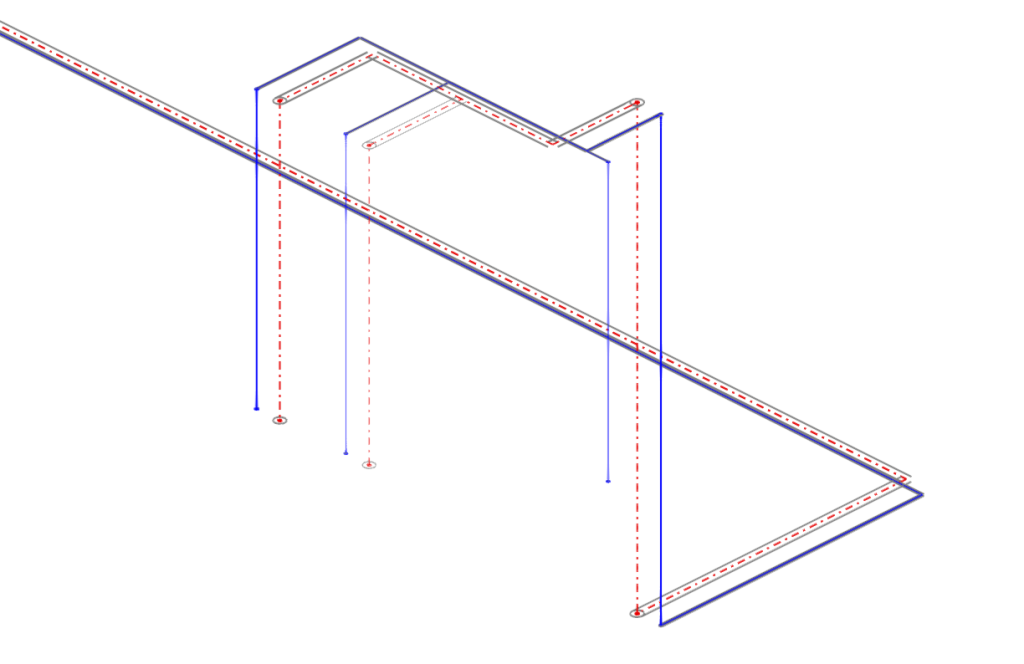

Inserting pipes into the water supply system

Within the "Installation" tab of the "Water Systems" tab, in the "Pipes" group of the main toolbar, there are options for entering the pipes of the water supply system:

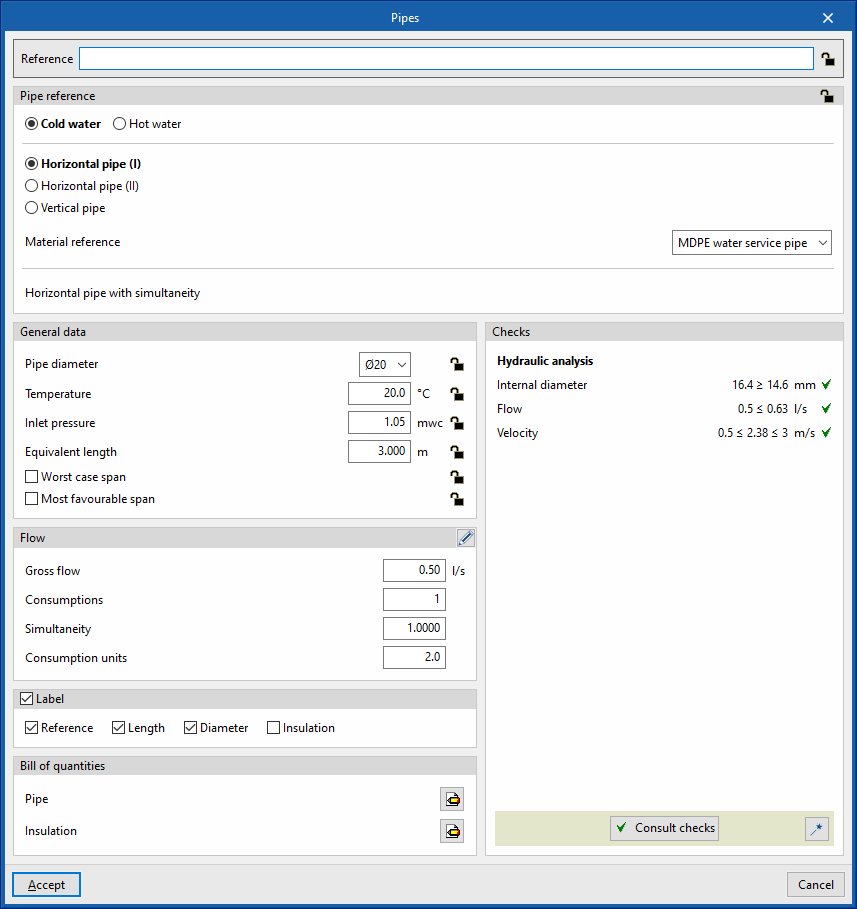

Pipe

Allows pipes to be inserted into the water supply system in any position.

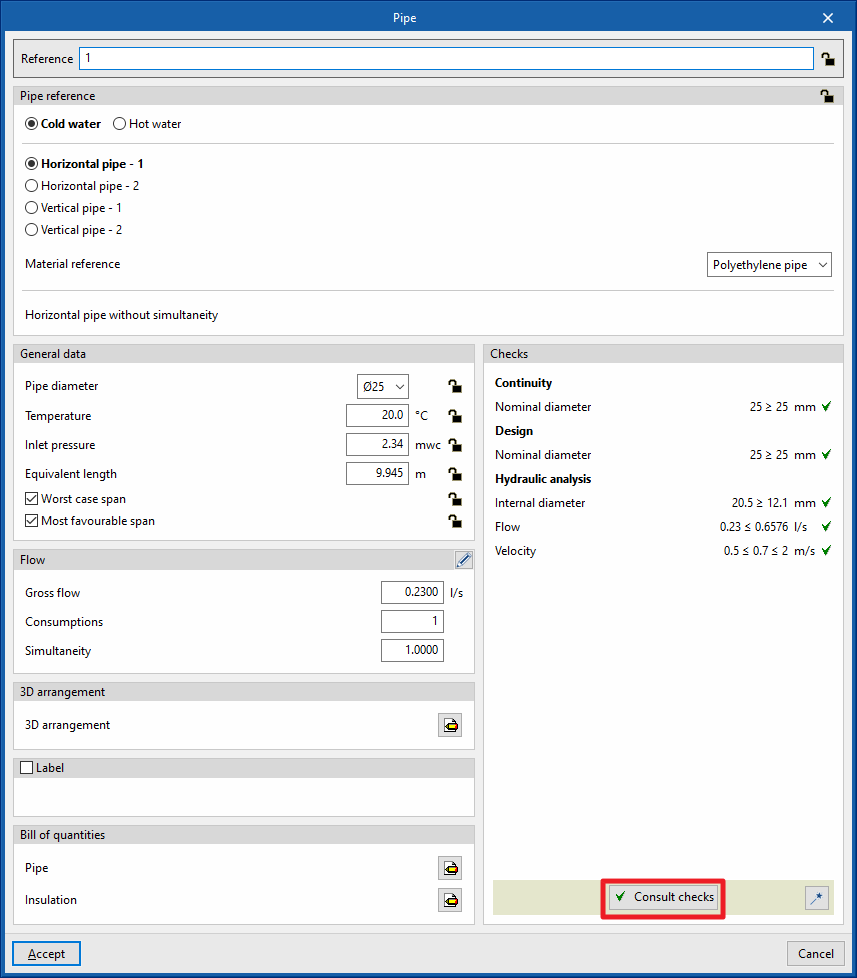

When inserting or editing a pipe, the following parameters can be configured. Some parameters only appear if the "Simplified entry" option, accessed from "Design options" under "General options", is deactivated:

- Reference

Element reference. This value can be locked or unlocked. If unlocked, the program will create or modify the reference when updating results. - Pipe reference

Allows the pipe type to be selected by its reference and depending on whether it is a "Cold water", "Hot water", "Hot water return", "Auxiliary supply" or "Auxiliary return" pipe. These types can be created and edited from the "Project" group, in the "Design and check options to be carried out" section of the "General options". The program also provides information on the "Material reference". The pipe reference can be locked or unlocked. If it is unlocked, the program can modify the pipe reference when updating results according to their arrangement in the model. - General data

Defines the element's general data. Some of these values can be locked or unlocked. If a value is locked, it is not modified when updating the results and remains unchanged.- Pipe diameter (Lock/Unlock)

Allows the pipe diameter to be selected from those available in the series. The materials and equipment in the system can be created and edited from "Material and equipment selection", in the "General options" of the "Project" group. - Temperature (Lock/Unlock)

- Inlet pressure (Lock/Unlock)

Defines the inlet pressure in the pipe. - Equivalent length (Lock/Unlock)

- Worse case span (optional) (Lock/Unlock)

- Most favourable span (optional) (Lock/Unlock)

- Pipe diameter (Lock/Unlock)

- Flow

Used to define the flow rate of the pipe. In the dialogue box accessible from the button on the right-hand side, the "Cold water flow rate" or "Hot water flow rate" values that will affect the upstream section that will feed the pipe being edited or entered can be specified. The values shown in the main pipe editing panel correspond to those of the pipe being edited or entered are as follows:- Gross flow

- Consumptions

- Simultaneity

- 3D layout

Used to check or edit the coordinates of the points of the polygonal line that defines the position of the pipe in the model. This section only appears when editing a previously entered pipe.- X, Y, Z

- Label (optional)

Manages the information visible in the element's label.- Reference

- Length

- Diameter

- Insulation

- Bill of quantities

Controls the generation of the element's bill of quantities using filters.- Pipe

- Insulation

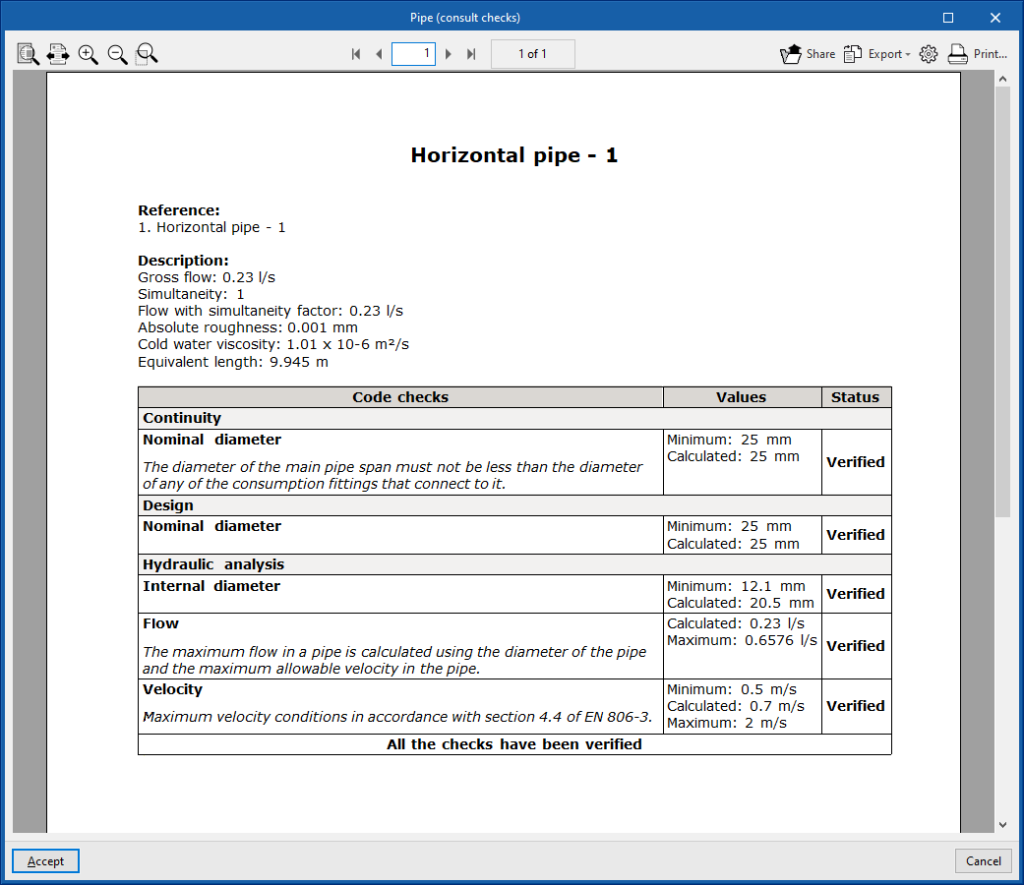

- Consult checks

Used to consult and list the checks carried out on the element. These checks can be activated, edited or deactivated from "Design and check options to be carried out", in the "General options" of the "Project" group. - Design

This tool, available from the button in the bottom right corner of the pipe editing panel, allows the pipe to be automatically designed to meet the defined checks.

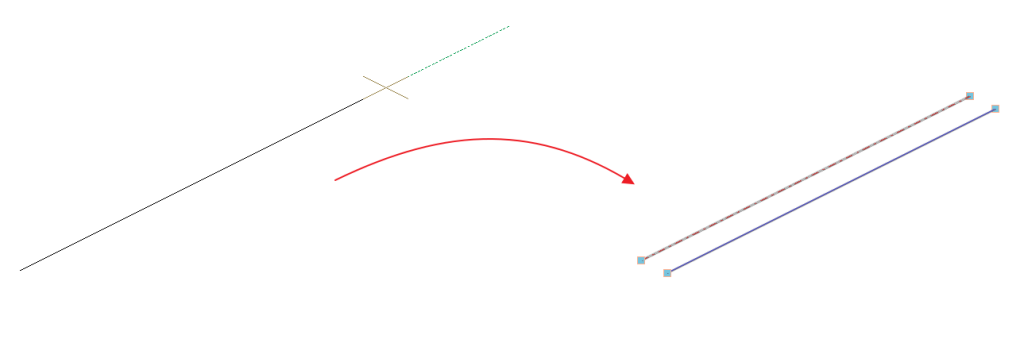

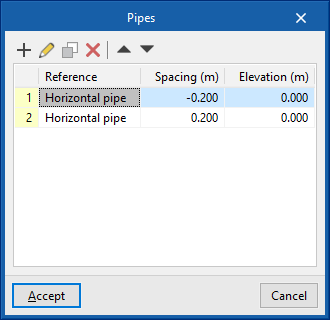

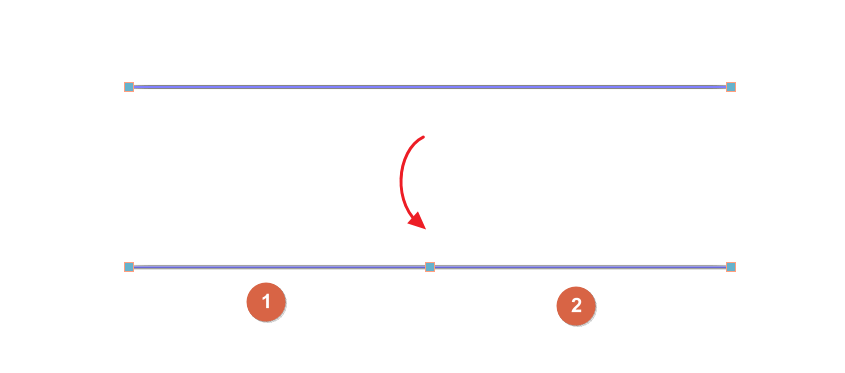

Multiple pipes

This option allows multiple or parallel pipes to be inserted into the water supply system in any position.

By clicking on this option, the program can define the characteristics and relative layout of one or more pipes by adding entries in the table. The following parameters must be entered:

- Reference

Reference of each pipe. - Spacing

Spacing of each pipe with respect to the insertion line in the model. - Elevation

The elevation of each pipe with respect to the insertion line in the model.

After being inserted, the model, geometry and properties of each of the pipes inserted using this option can be edited like any other pipe, without maintaining a link with the other pipes inserted at the same time.

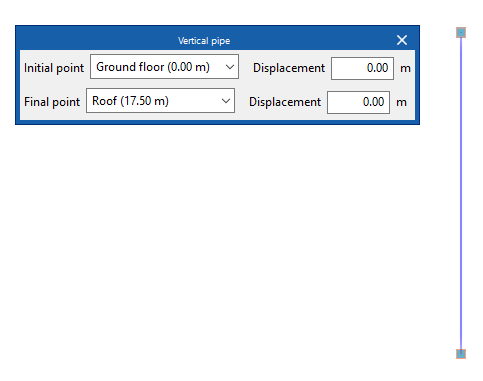

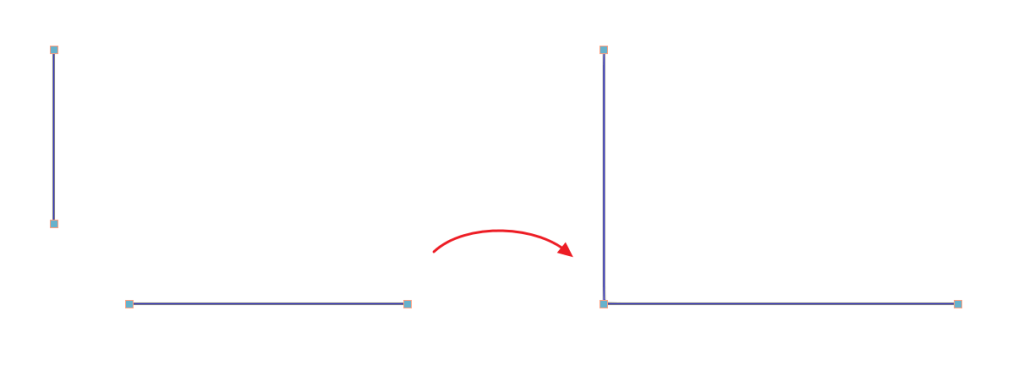

Pipes between levels

The "Between levels" option is used to insert water supply pipes between levels.

When clicking on this option, the program can define the pipe properties by means of an editing panel identical to the one that appears when using the "Pipe" option.

Then, in the "Properties - Vertical pipe" dialogue box, the level associated with the "Final point" of the pipe is defined, together with a "Displacement" above the indicated level, expressed in positive or negative values.

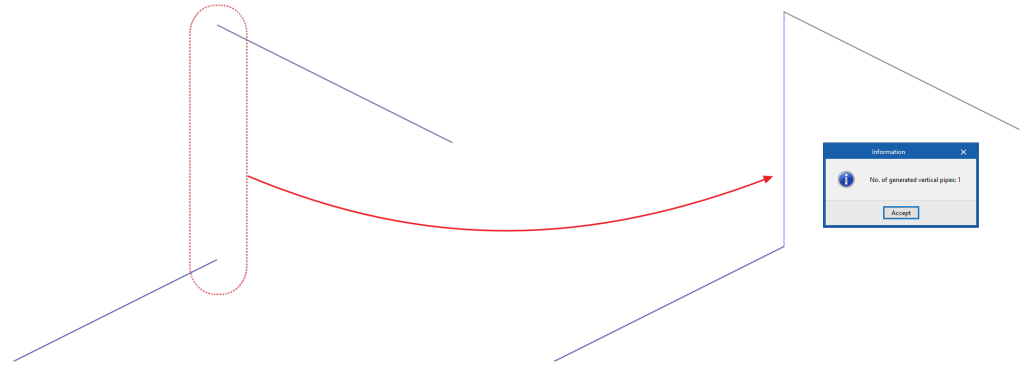

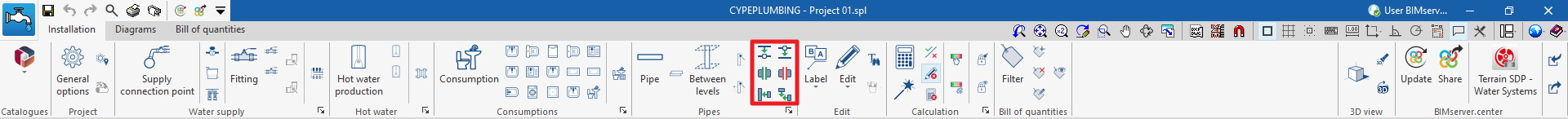

Generating vertical pipes

The program offers two tools for the automatic generation of vertical pipes connecting other elements (e.g. pipes or consumptions) previously arranged in the model.

- The first option generates the vertical pipes at all points of the job where possible.

- The second option generates the vertical pipes between the elements selected by the user, if possible.

After using any of these tools, the program reports the number of generated vertical pipes. From here, users can edit or delete the pipes created in the process if they wish to do so.

Esta herramienta solamente genera una tubería vertical entre dos elementos This tool only generates a vertical pipe between two elements located at different heights if their ends, or if the points where the vertical connection pipe is to be placed, have the same coordinates on the plan.

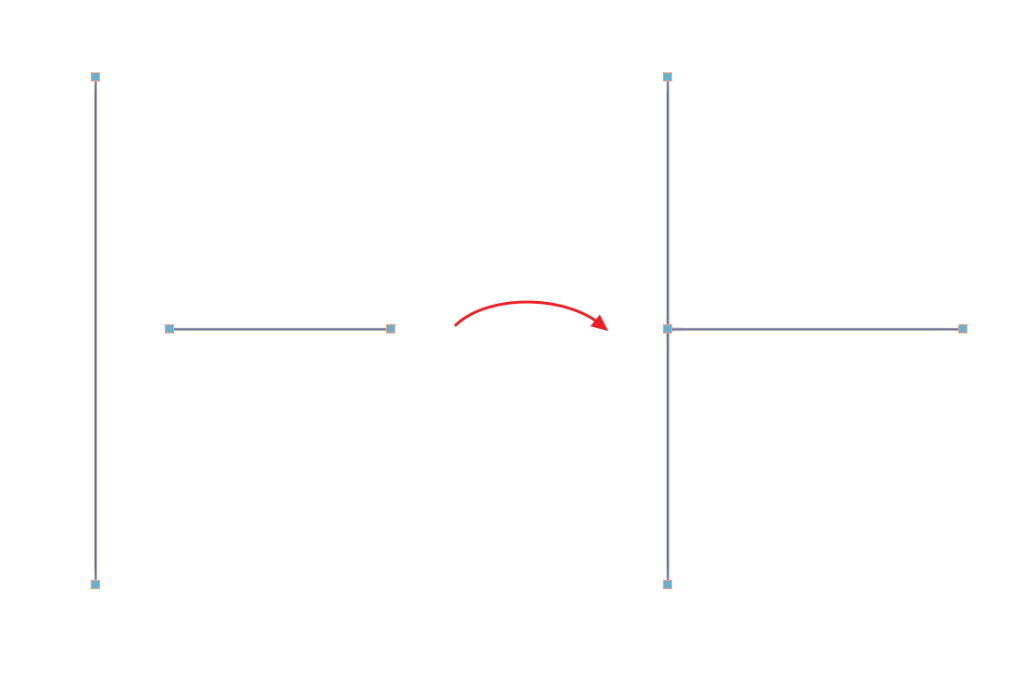

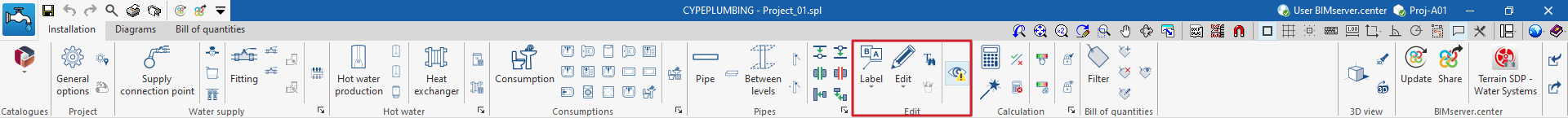

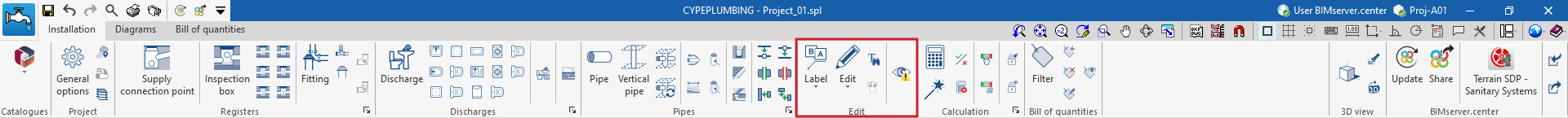

Editing pipes in water supply and evacuation systems

In the "Installation" tab under the "Water Systems" tab, in the "Pipes" group of the main toolbar, there are options for editing the geometry of the water supply system pipes:

These features are also available for editing the pipe geometry of the water evacuation system in the "Installation" tab under the "Sanitary Systems" tab in the "Pipes" group of the main toolbar:

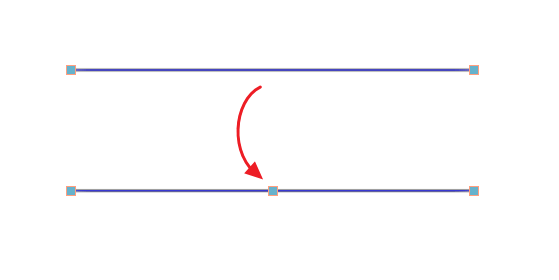

Add points

Adds intermediate points to pipes. The pipe remains as a single element without being divided.

Delete points

Deletes intermediate points of the pipes. The pipeline remains as a single element without being divided.

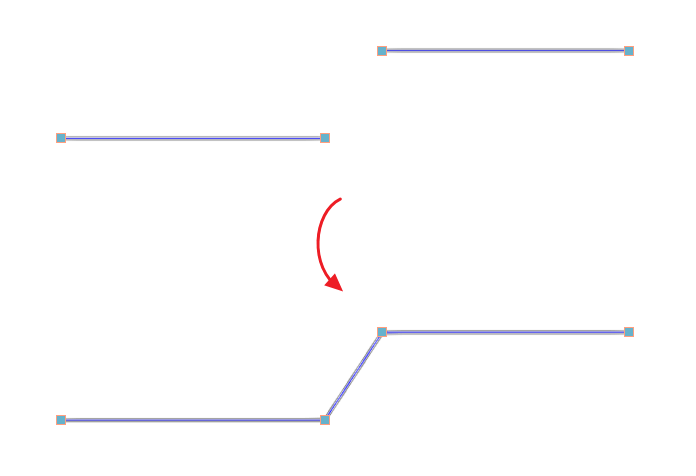

Join

Joins two pipes into a single pipe, generating the connection span if necessary. The resulting pipe adopts the properties of the first pipe selected when using the option.

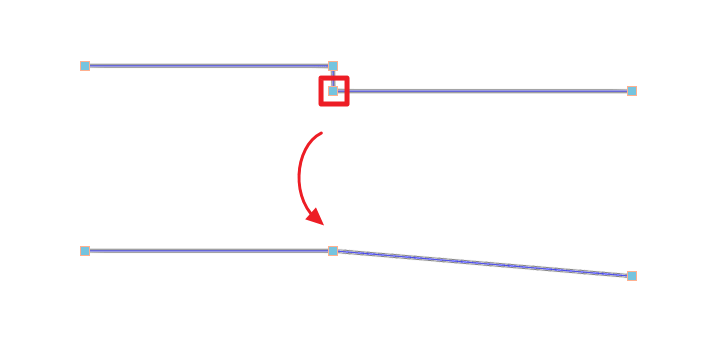

Extend/trim element

Used to lengthen or shorten a pipe with respect to a reference pipe. The first selected pipe serves as a reference, while the second selected pipe is lengthened or shortened after using the option. The program can be used to preview the resulting geometry when the second selection is made.

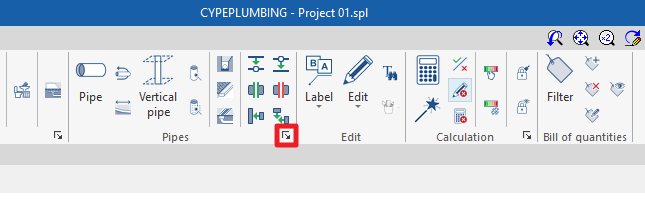

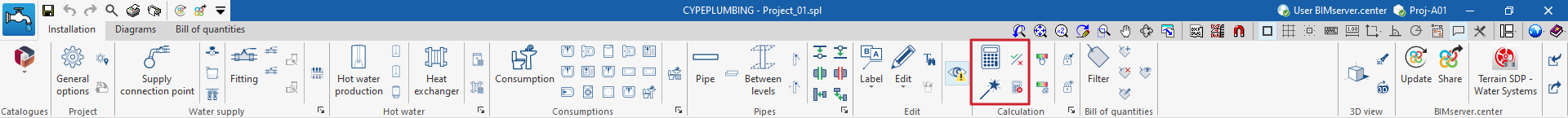

Editing tools

In the "Edit" group of the main toolbar of the "Installation" tab, either in the "Water Systems" tab or in the "Sanitary Systems" tab, the following tools can be found:

Label

The options in this menu allow the following operations to be performed on the element labels:

| Move tag in 2D mode | Moves the selected tag on the element's floor plan. | |

| Move tag in 3D mode | Moves the selected tag in the 3D space. | |

| Move tag to the initial point | Returns the tag of the selected element to the initial point. | |

| Show/hide tag | Shows or hides the selected element's tag. | |

| Place or remove the reference line of the tag | Shows or hides the line linking the tag to the selected element it refers to. | |

| Rotate tag | Rotate the tag over its position. | |

| Label | Edits the composition of the labels of different categories of elements and the size of the text. |

Edit

The options in this menu allow the following editing operations to be carried out on the elements of the system entered in the model:

| Edit | Edits the parametric properties of the selected element in the model. | |

| Delete | Deletes a previously entered element. | |

| Move element | Moves an element or a node of an element. | |

| Move a group of elements | Moves a group of elements. | |

| Rotate element | Rotates an element about the "x", "y" or "z" axis. | |

| Rotate a group of elements | Rotate a group of elements. | |

| Copy | Creates a copy of one or more elements. | |

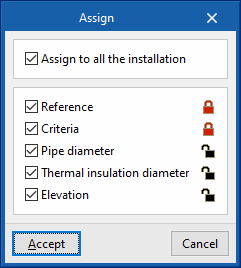

| Assign | Assigns the parametric properties of the selected element to other elements. | |

| Symmetry (copy) | Copies a selection of elements with symmetry with respect to a vertical plane defined by two points. | |

| Symmetry (move) | Moves a selection of elements with symmetry about a vertical plane defined by two points. | |

| Copy onto another floor plan | Creates a copy of the selected elements in the desired floor plans. This feature is only available on floor plans. | |

| Measure lengths on plan | Measures lengths and angles between points defined in the model. If a closed outline is selected, it also indicates the area. | |

| Projection | Switches to the plan projection (XY plane) in the work area. |

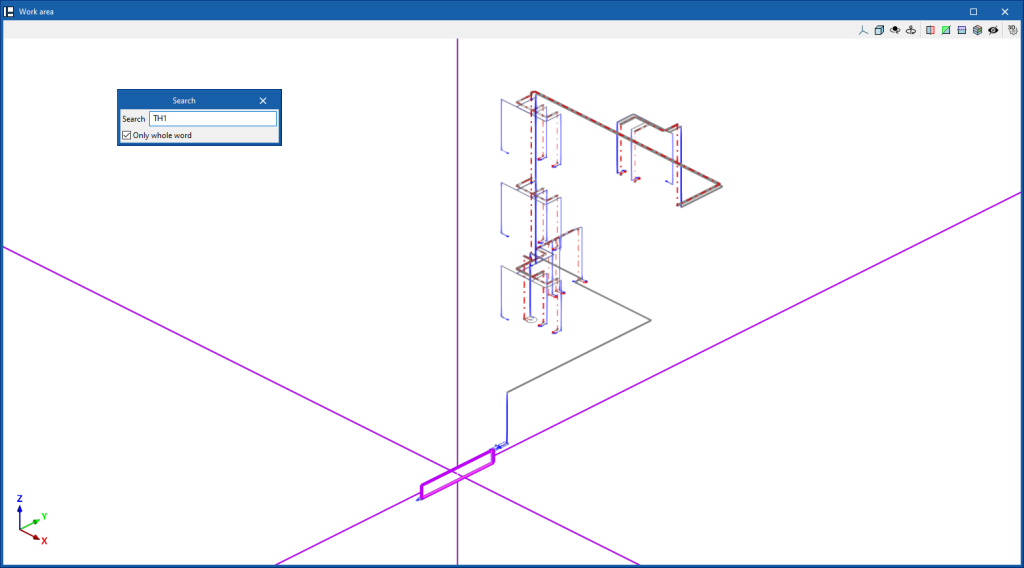

Search

Searches for an element by entering a text with its full reference or part of its reference.

- Only whole word (optional)

If this box is checked, only the elements that match the entered text in full will be searched for.

When doing this, the program locates the element in the model by means of magenta lines in the main directions of the space and an enveloping volume of the same colour.

Drawing

The options in this menu allow the following drawing resources to be entered in a plan view:

| Elevation | Enters an elevation between two selected points, indicating the line colour, line thickness, and text size. | |

| Line | Inserts a line between two selected points, indicating its colour and thickness. | |

| Text | Enter a text and a reference line, indicating its colour, the line thickness and the text size. | |

| Text box | Enter a left-aligned, right-aligned or centred text box, indicating the colour and size of the text, the properties of the frame and the background fill. | |

| Arc | Enter an arc and, optionally, its radius, indicating the line colour, line thickness and text size. | |

| Circle | Enter a circle and its radius or diameter, optionally, indicating the line colour, line thickness, and text size. | |

| Rectangle | Enter a rectangle and, optionally, its area, indicating the line colour, line thickness and text size. | |

| Area | Enter a dotted polygon and, optionally, its area, indicating the line colour, line thickness, and text size. | |

| Polyline | Inserts a polyline by points, indicating its colour and thickness. | |

| Edit | Edit the properties of the selected drawing resource. | |

| Delete | Deletes the selected drawing resources. | |

| Move | Moves the selected drawing resource or parts of it. | |

| Assign | Enter a circle and its radius or diameter, optionally, indicating the line colour, line thickness, and text size. |

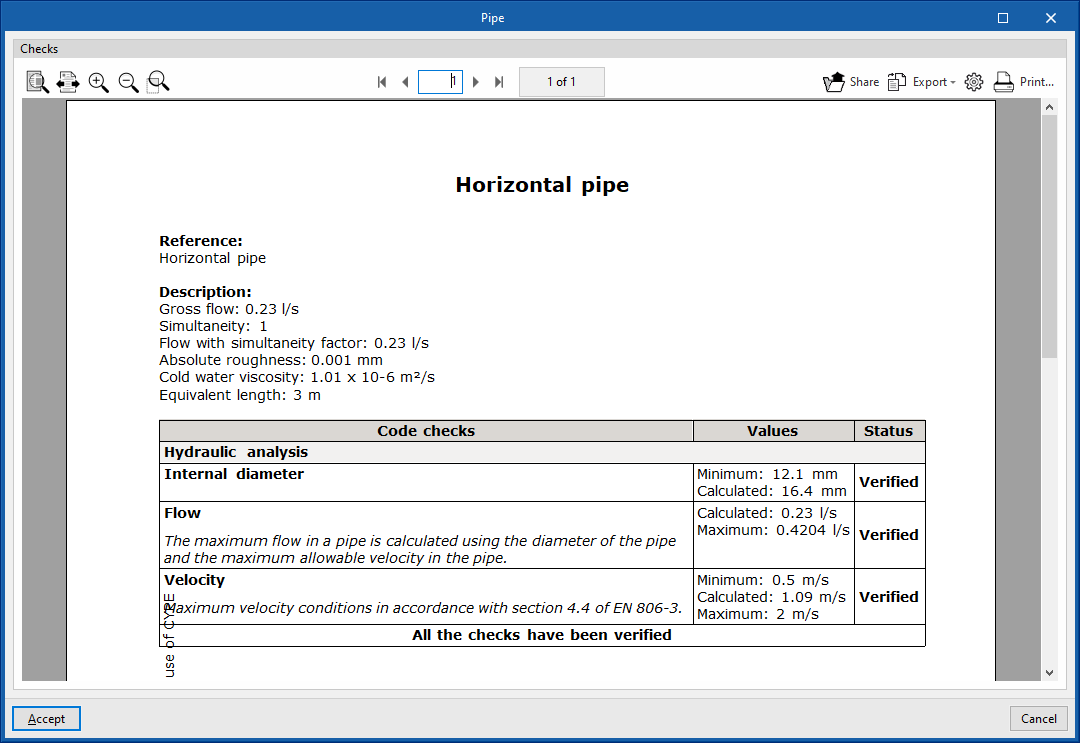

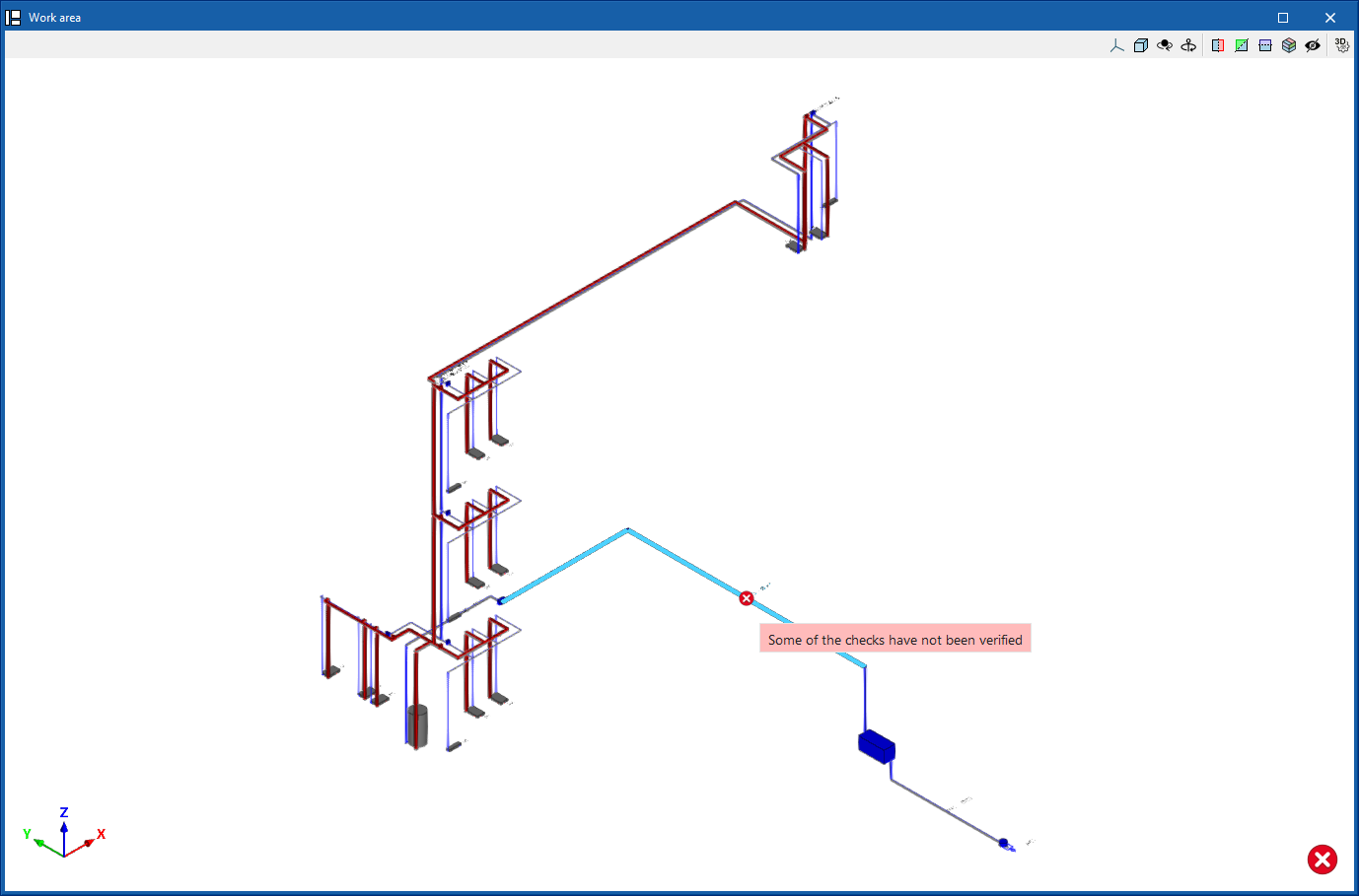

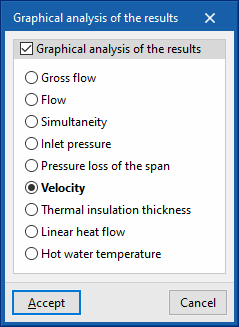

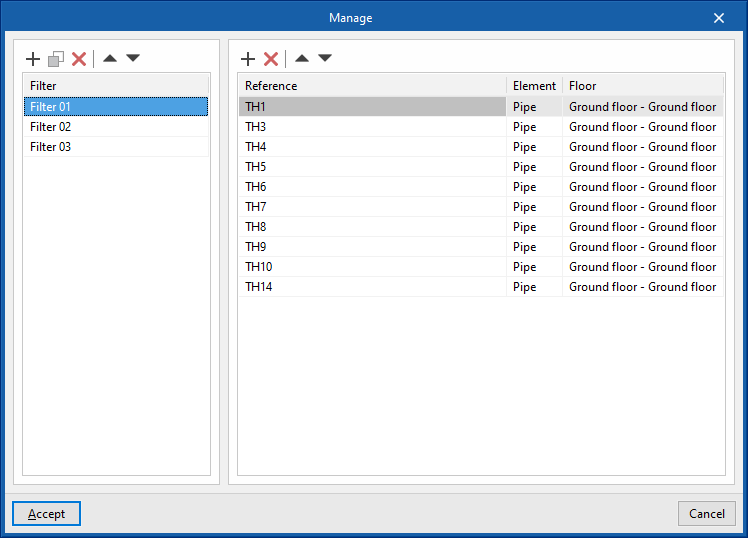

Check