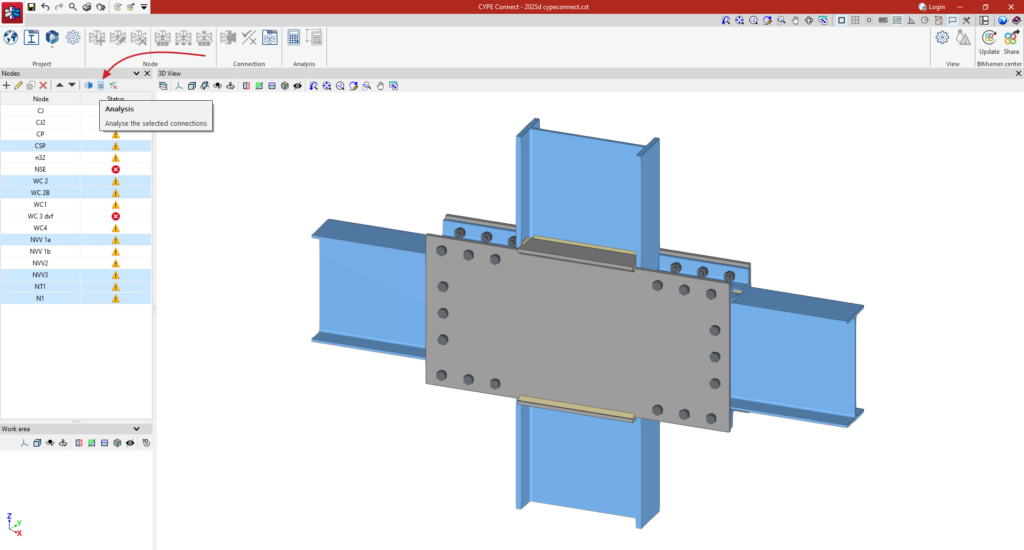

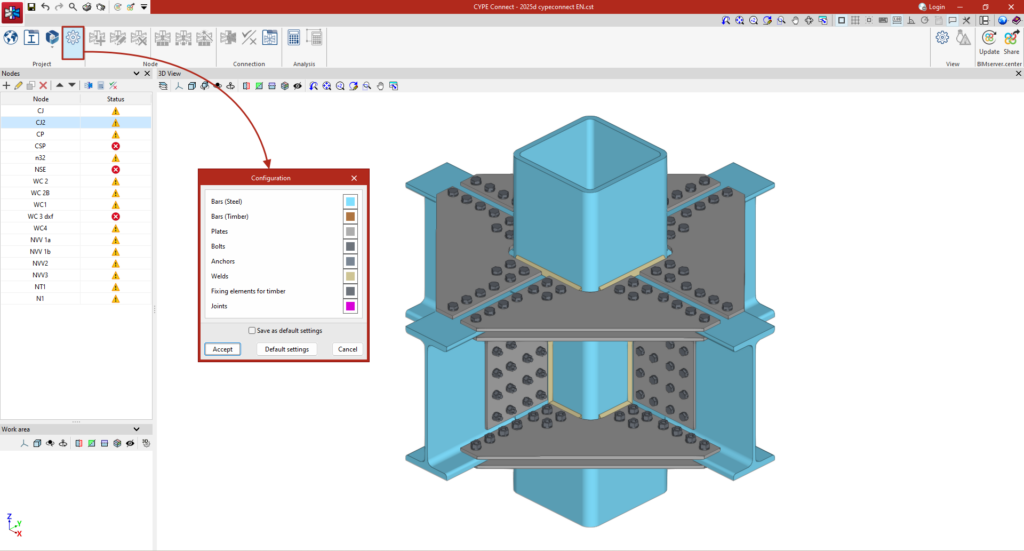

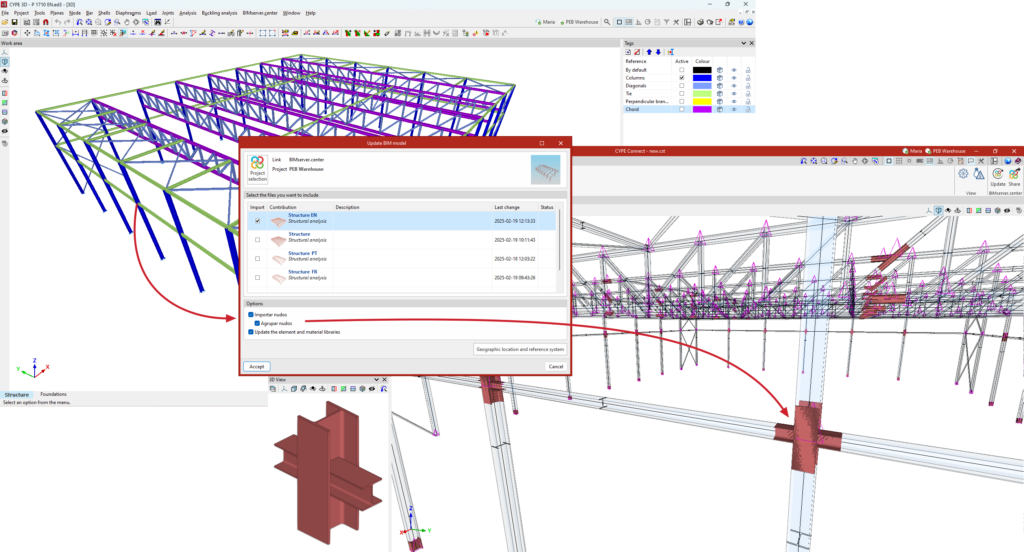

In version 2025.d, CYPE Connect incorporates a new tool for analysing selected connections directly from the list of nodes.

In previous versions, the program could analyse selected connections, but this selection had to be made exclusively from the 3D view of the structure.

Now with this update, the tool, located at the top of the list of connections, can be used to select and analyse connections directly from the list.